BOSCH REXROTH

R901000131

Prefill Valves

Check valves: SFE 50.-1x/

BOSCH REXROTH

MATERIAL: R901000131

SUMMARY: Check valves: SFE 50.-1x/

Quantity in stock: 0

Type "SEF . Z" (with optional cover type "LFF")

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

||

|

SFE |

0 |

– |

1X |

/ |

M |

* |

|

01 |

Prefill valves |

SFE |

|

02 |

Size 25 |

25 |

|

Size 32 |

32 |

|

|

Size 40 |

40 |

|

|

Size 50 |

50 |

|

|

Size 63 |

63 |

|

|

Size 80 |

80 |

|

|

Size 100 |

100 |

|

|

03 |

Block installation |

P |

|

Cylinder installation 1) |

Z |

|

|

04 |

without pre-decompression |

0 |

|

05 |

Component series 10 ... 19 (10 ... 19: unchanged installation and connection dimensions) - Size 10 |

1X |

|

Seal material |

||

|

06 |

NBR seals (other seals on request) |

M |

|

Observe compatibility of seals with hydraulic fluid used. |

||

|

07 |

Further details in the plain text |

* |

1) Control cover type “LFF” incl. matching mounting kit (separate order, see page 8):

With NG25 and 32, alternative control covers type "LFA.D-7X/....F…" (see RE 21010) may be used.

general

|

Size |

25 | 32 | 40 | 50 | 63 | 80 | 100 | |

|

Weight |

kg |

0.53 | 1.05 | 1.94 | 3.2 | 6.48 | 10.3 | 22.15 |

|

Installation position |

any | |||||||

|

Ambient temperature range 1) |

°C |

-30 … +80 | ||||||

| 1) | NBR seals |

hydraulic

|

Size |

25 | 32 | 40 | 50 | 63 | 80 | 100 | ||

|

Maximum operating pressure |

Port P |

bar |

350 | ||||||

|

Anschluss A |

bar |

16 | |||||||

|

Port B |

bar |

350 | |||||||

|

Anschluss X |

bar |

150 | |||||||

|

Cracking pressure 1) |

bar |

≈ 0.12 | |||||||

|

Maximum flow 2) |

Case of application 1 |

l/min |

100 | 170 | 240 | 360 | 580 | 810 | 1210 |

|

Case of application 2 |

l/min |

90 | 140 | 200 | 320 | 510 | 710 | 1070 | |

|

Case of application 3 |

l/min |

60 | 100 | 140 | 220 | 350 | 480 | 730 | |

|

Case of application 4 |

l/min |

50 | 70 | 100 | 160 | 260 | 360 | 540 | |

|

Druckflüssigkeit |

Mineral oil (HL, HLP) to DIN 51524;fast bio-degradable hydraulic fluids according to VDMA 24568; HETG (rape seed oil); other hydraulic fluids on enquiry | ||||||||

|

Hydraulic fluid temperature range |

°C |

-30 … +80 | |||||||

|

Viscosity range |

mm²/s |

10 … 800 | |||||||

|

Maximum admissible degree of contamination of the hydraulic fluid 3) |

Class 20/18/15 according to ISO 4406 (c) | ||||||||

| 1) | Pressure differential at the main poppet for overcoming the spring force |

| 2) | Pulling function (A to B) |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

Flow ‒ case of application 1 (A to B)

Flow ‒ case of application 2 (A to B)

Size of the filling tank at least 1.5 x cylinder content

Flow ‒ case of application 3 (A to B)

Flow ‒ case of application 4 (A to B)

Attention!

Faulty dimensioning of prefill valves and connection lines may lead to cavitation effects. The consequences affect the reliability and durability of products!

Attention!

An underdimensioned prefill valve and/or an underdimensioned line leads to gas leaks from the hydraulic fluid with corresponding consequences and often to long-term damage at the cylinder seals.

Notice!

For limit areas, please contact us. It is often sufficient, to select a pipeline which is one size larger.

|

1 |

Cylinders |

|

2 |

Prefill valve |

|

a |

at least 300 mm with extended cylinder |

|

b |

up to 1000 mm with the specified maximum flows |

|

c |

≤ 500 mm |

|

h |

300 mm ≤ h ≤ 500 mm |

For applications outside these parameters, please consult us!

(measured with HLP46, ϑOil {ν = [si]40 mm2/s[/si][imp]40 cSt[/imp]) = [si]40 ±5 °C[/si][imp]104 ±41 °F[/imp])

NG25

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG25

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

Size 32

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

Size 32

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG40

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG40

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG50

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG50

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG63

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG63

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG80

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

NG80

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

Size 100

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

Size 100

Pressure differential Δp between ports A and B dependent on the flow qV in suction direction.

Prefill valve type SFE

Prefill valve type SFE with control cover type LFF

Installation bore for block installation type SFE . P

Dimensions in mm

| 1) | Fit |

Installation bore for block installation type SFE . P

Dimensions in mm

| 1) | Fit |

|

1 |

Port A can be positioned anywhere around the central axis. However, it must be observed that the control bores and the mounting bores are not damaged! |

|

2 |

Block |

|

3 |

Cylinders |

|

NG |

ØD1H7 / ØD8 |

ØD2H7 / ØD7 |

ØD3 |

ØD4 |

ØD5 |

ØD6 |

H1 |

P1 1) |

P2 1) |

T1 |

T2 |

T3 |

T4 |

T5 |

||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| 25 | 43 | 37 | 25 | - 5 | 36 | 25 | 7 | 7 | 30 | 13 | 70 | + 0.1 | 56 | 43.5 | 2.5 | 2.5 |

| 32 | 58 | 50 | 31 | - 5 | 46 | 32 | 7 | 9 | 30 | 13 | 78 | + 0.1 | 63 | 47 | 2.5 | 2.5 |

| 40 | 75 | 55 | 40 | - 5 | 58 | 40 | 7 | 11 | 26 | 16 | 81 | + 0.1 | 63 | 43 | 3 | 3 |

| 50 | 90 | 68 | 50 | - 5 | 71 | 50 | 7 | 14 | 31 | 20 | 100 | + 0.1 | 78 | 53 | 4 | 3 |

| 63 | 120 | 90 | 63 | - 5 | 90 | 60 | 7 | 16 | 32 | 23 | 114 | + 0.1 | 89 | 59 | 4 | 4 |

| 80 | 145 | 110 | 78.5 | - 5 | 107 | 76 | 7 | 18 | 36 | 23 | 134 | + 0.1 | 109 | 71 | 5 | 5 |

| 100 | 180 | 135 | 95 | - 5 | 132 | 93 | 7 | 30 | 60 | 30 | 180 | + 0.1 | 148 | 101 | 8 | 8 |

| 1) | Fit |

Installation bore for cylinder installation type SFE . Z

Dimensions in mm

| 1) | Fit |

Installation bore for cylinder installation type SFE . Z

Dimensions in mm

| 1) | Fit |

|

1 |

Port A can be positioned anywhere around the central axis. However, it must be observed that the control bores and the mounting bores are not damaged! |

|

2 |

Cover |

|

3 |

Cylinders |

|

NG |

ØD1H7 / ØD8 |

ØD2H7 / ØD7 |

ØD3 |

ØD4 |

ØD5 |

ØD6 |

H1 |

P1 1) |

P2 1) |

T1 |

T2 |

T3 |

T4 |

||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| 25 | 43 | 45 | 25 | - 5 | 36 | 25 | 7 | 7 | 27 | 83 | 85 | + 0.1 | 60 | 41 | 2.5 |

| 32 | 58 | 60 | 31 | - 5 | 46 | 32 | 7 | 9 | 28 | 89.5 | 91.5 | + 0.1 | 66 | 44 | 2.5 |

| 40 | 75 | 78 | 40 | - 5 | 58 | 40 | 7 | 11 | 30 | 91 | 93 | + 0.1 | 71 | 50 | 3 |

| 50 | 90 | 90 | 50 | - 5 | 71 | 50 | 7 | 14 | 34 | 110 | 112 | + 0.1 | 85 | 59 | 4 |

| 63 | 120 | 123 | 63 | - 5 | 90 | 60 | 7 | 16 | 40 | 128 | 130 | + 0.1 | 101 | 71 | 4 |

| 80 | 145 | 150 | 78.5 | - 5 | 107 | 76 | 7 | 18 | 40 | 148 | 150 | + 0.1 | 117 | 79 | 5 |

| 100 | 180 | 185 | 95 | - 5 | 132 | 100 | 7 | 30 | 50 | 188 | 200 | + 0.1 | 152 | 101 | 8 |

| 1) | Fit |

Installation bore and connection dimensions according to ISO 7368

Dimensions in mm

Installation bore and connection dimensions according to ISO 7368

Dimensions in mm

Tolerances:

General tolerances ISO 2768-mK Tolerancing principle ISO 8015Dimensions

|

NG |

ØD2 |

ØD3H13 |

L1 |

L2 |

L3 |

L4 |

L5 |

H1 |

|

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| 25 | 6 | - 0.5 | 5 | 85 | 58 | 29 | 33 | 16 | 25 |

| 32 | 8 | - 0.5 | 5 | 102 | 70 | 35 | 41 | 17 | 35 |

| 40 | 10 | - 0.5 | 5 | 125 | 85 | 42.5 | 50 | 23 | 45 |

| 50 | 10 | - 0.5 | 8 | 140 | 100 | 50 | 58 | 30 | 45 |

| 63 | 12 | - 0.5 | 8 | 180 | 125 | 62.5 | 75 | 38 | 65 |

| 80 | 16 | - 0.5 | 10 | 250 | 200 | - | - | - | 50 |

| 100 | 20 | - 0.5 | 10 | 300 | 245 | - | - | - | 63 |

Poppet geometry and determination of the minimum pilot pressure

Dimensions in mm

Poppet geometry and determination of the minimum pilot pressure

Dimensions in mm

|

A1 |

Effective area of the main poppet |

|

A2 |

Effective area of the control spool |

|

s1 |

Stroke of the main poppet |

|

s2 |

Stroke of the control spool |

|

F1 |

Spring force of the valve spring |

|

F2 |

Spring force of the compression spring of the control spool |

|

Vst X |

Pilot volume for opening the valve |

|

pÖ |

Cracking pressure (pressure differential at the main poppet for overcoming the spring force F1) |

|

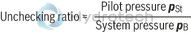

pSt |

Pilot pressure at port X |

|

pB |

System pressure at port B |

|

|

NG |

A1 |

A2 |

s1 |

s2 |

F1 |

F2 |

VstX |

Unchecking ratio |

|

cm² |

cm² |

mm |

mm |

N |

N |

cm³ |

||

| 25 | 5.31 | 1.33 | 6.2 | 5 | 6 … 14 | 38 … 70 | 0.66 | 4 |

| 32 | 8.04 | 2.01 | 8.5 | 6.5 | 9 … 22 | 58 … 109 | 1.3 | 4 |

| 40 | 13.52 | 3.14 | 10 | 7 | 14 … 29 | 93 … 162 | 2.2 | 4.3 |

| 50 | 21.24 | 4.71 | 12.5 | 9 | 23 … 49 | 149 … 261 | 4.2 | 4.5 |

| 63 | 32.67 | 7.07 | 14.5 | 11 | 35 … 63 | 206 … 348 | 7.8 | 4.6 |

| 80 | 49.02 | 10.18 | 17 | 13 | 57 … 127 | 310 … 579 | 13.2 | 4.8 |

| 100 | 73.13 | 15.9 | 22 | 16 | 81 … 193 | 476 … 952 | 25.5 | 4.6 |

Example: Type SFE32...

pB = 30 bar [435 psi];

pSt = 4.0 x 30 bar [435 psi] = 129 bar [1740 psi]