SUN HYDRAULICS

XQILLANBM

$2,131.40 USD

Tags:

- SUN HYDRAULICS

- Material:XQILLANBM

- Model:XQIL-LAN-BM

- Summary:Y-assembly

Quantity in stock: 0

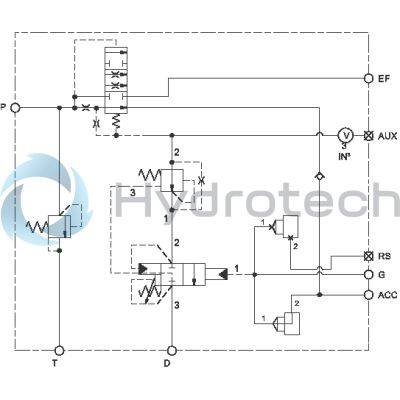

The Sun Hydraulics XQILLANBM (Material Number: XQILLANBM) is a sophisticated valve assembly designed specifically for charging an accumulator using a fixed displacement pump. This assembly features a ventable priority flow control valve that efficiently manages system pressure. When the pressure reaches the set point, the valve vents, allowing all pump flow to be available to the system. Conversely, when the pressure drops, a fixed percentage of pilot valve control ensures that priority flow recharges the accumulator, maintaining system efficiency by directing only necessary flow to the accumulator while leaving remaining pump flow accessible for other system needs. The assembly incorporates several key features: a circuit that softens pump unloading, an overpressure relief system, and provisions for remote sensing of accumulator pressure. A separate drain line is essential to prevent erratic operations due to tank line pressure fluctuations. It's crucial to select an appropriate adjustment range since operating pressures and flows significantly influence unloading valve performance. The design includes large porting relative to its capacity, encouraging large piping use to minimize issues from flow-induced pressure drops. The spool design in the pilot valve maintains a consistent differential ratio due to non-wearing diameters on the spool. The accumulator pilot valve must be set below any reliefs in the pump side of the system to avoid severe heating. This line mount body type assembly has a capacity of 120 gpm (480 L/min) and requires careful consideration of maximum system pressures as manifolds made from aluminum are not rated beyond 3000 psi (210 bar). Remote sensing can enhance accuracy in accumulator charge pressure management by minimizing circuit errors through strategic plug interchange and connection adjustments.

This valve assembly is meant to charge an accumulator using a fixed displacement pump. It incorporates a ventable priority flow control valve. When the pressure reaches the set point of the valve, the priority flow control is vented and all of the pump flow is available to the system. When the pressure drops to the value determined by the fixed percentage of the pilot valve, the priority flow is used to recharge the accumulator. Only the priority flow is directed to the accumulator leaving the rest of the pump flow available to the system. The assembly has three additional features; a simple circuit that softens the unloading of the pump, a system over-pressure relief, and provisions for remote sensing of the accumulator pressure.

- When applying this assembly, a separate drain line is required to prevent erratic operation caused by tank line pressure fluctuations.

- NOTE: Careful consideration should be given when selecting an adjustment range. System pressure drops and flows tend to affect the operation of unloading valves. Low operating pressures combined with low differentials result in a very narrow band between unload and reset, requiring precise system design. High flow rates typically mean high pressure drops, which subtract from the differential the valve has to work with.

- The pressure setting and the resultant reseat pressure are in reference to the port 1 area of the QPA* pilot valve. Pump pressure will be higher and accumulator pressure will be lower due to pressure drop caused by flow. Use of the remote sense for accumulator pressure will minimize the error on the accumulator side of the circuit. Use of the remote sense is highly recommended.

- The porting on this assembly is large in relation to its capacity. This is done to encourage the use of correspondingly large piping to minimize problems caused by flow induced pressure drop.

- The spool design of the pilot valve allows it to maintain a fixed differential ratio because the areas are created by diameters on the spool that will not wear or change with use.

- The accumulator pilot valve must be set below any reliefs in the pump side of the system or severe heating could occur.

- The relief in this package is meant to be an over-pressure device. It is set higher than the highest setting of the pilot valve and capped.

| Capacity | 120 gpm480 L/min. |

| Body Type | Line mountLine mount |

| Mounting Hole Thread | .375-16 UNC - 2B in..375-16 UNC - 2B in. |

| Mounting Hole Depth | .88 in.22,4 mm |

| Mounting Hole Quantity | 33 |

Show FAQ

Additional Resources

- Integrated Packages: Solutions That Grow Your Reputation

- Fluid and Temperature Recommendations

- Sun's Floating Style Screw-In Cartridge

- Sun Model Code Explanation; 999-901-334

- Custom Integrated Packages from Sun

Notes:

- Some applications may require additional volume for a smoother shift. Should this become necessary, an auxillary port has been provided to attach a length of hose for additional volume.

- Remote sensing of accumlator charge pressure can be achieved by interchanging cavity plugs XZCC and XZOC, and connecting RS port to Accumulator.

- Important: Carefully consider the maximum system pressure. The pressure rating of the manifold is dependent on the manifold material, with the port type/size a secondary consideration. Manifolds constructed of aluminum are not rated for pressures higher than 3000 psi (210 bar), regardless of the port type/size specified.