SUN HYDRAULICS

XQGFLANAN

$1,177.60 USD

Tags:

- SUN HYDRAULICS

- Material:XQGFLANAN

- Model:XQGF-LAN-AN

- Summary:Y-assembly

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

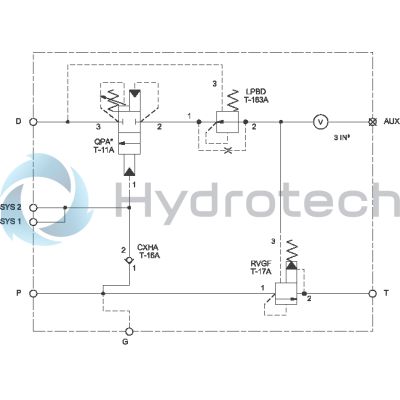

The Sun Hydraulics XQGFLANAN (XQGFLANAN) is a specialized valve assembly designed to efficiently manage accumulator charging using a fixed displacement pump. This assembly excels in maintaining system pressure by unloading the pump when the set pressure point is reached and re-engaging it when the pressure drops to a predetermined level, as dictated by the pilot valve's fixed percentage. A notable feature of this valve assembly is its ventable relief, which not only serves as a main stage for unloading the pump but also acts as an overpressure relief for the system. Additionally, it includes a simple circuit that softens the pump's unloading process, thereby enhancing operational smoothness. The XQGFLANAN is constructed with durability in mind, featuring a line mount body type with mounting hole threads of .375-16 UNC 2B and a depth of .88 inches. It requires three mounting holes for secure installation. The manifold material used in this assembly is 6061-T651 aluminum, chosen for its strength, cost-effectiveness, machinability, and excellent corrosion resistance. Despite these properties, it is important to note that manifolds made from this material are not rated for pressures exceeding 3000 psi (210 bar), regardless of port type or size. For applications requiring additional volume to achieve smoother shifts, an auxiliary port is available to attach a hose for added capacity. This thoughtful design consideration ensures adaptability across various operational needs while maintaining system integrity. The Sun Hydraulics XQGFLANAN provides robust performance and reliability in hydraulic systems where precise control of accumulator charging and pressure regulation are critical.

The Sun Hydraulics XQGFLANAN (XQGFLANAN) is a specialized valve assembly designed to efficiently manage accumulator charging using a fixed displacement pump. This assembly excels in maintaining system pressure by unloading the pump when the set pressure point is reached and re-engaging it when the pressure drops to a predetermined level, as dictated by the pilot valve's fixed percentage. A notable feature of this valve assembly is its ventable relief, which not only serves as a main stage for unloading the pump but also acts as an overpressure relief for the system. Additionally, it includes a simple circuit that softens the pump's unloading process, thereby enhancing operational smoothness. The XQGFLANAN is constructed with durability in mind, featuring a line mount body type with mounting hole threads of .375-16 UNC 2B and a depth of .88 inches. It requires three mounting holes for secure installation. The manifold material used in this assembly is 6061-T651 aluminum, chosen for its strength, cost-effectiveness, machinability, and excellent corrosion resistance. Despite these properties, it is important to note that manifolds made from this material are not rated for pressures exceeding 3000 psi (210 bar), regardless of port type or size. For applications requiring additional volume to achieve smoother shifts, an auxiliary port is available to attach a hose for added capacity. This thoughtful design consideration ensures adaptability across various operational needs while maintaining system integrity. The Sun Hydraulics XQGFLANAN provides robust performance and reliability in hydraulic systems where precise control of accumulator charging and pressure regulation are critical.

This valve assembly is meant to charge an accumulator using a fixed displacement pump. When the pressure reaches the set point of the valve, the pump is unloaded. When the pressure drops to the value determined by the fixed percentage of the pilot valve, the pump is brought back on line to recharge the accumulator. The ventable relief serves a dual purpose as a main stage to unload the pump and as a system over-pressure relief. The assembly has an additional feature; a simple circuit that softens the unloading of the pump.

| Body Type | Line mountLine mount |

| Mounting Hole Thread | .375-16 UNC - 2B in..375-16 UNC - 2B in. |

| Mounting Hole Depth | .88 in.22,4 mm |

| Mounting Hole Quantity | 33 |

Show FAQ

Additional Resources

- Integrated Packages: Solutions That Grow Your Reputation

- Fluid and Temperature Recommendations

- Sun's Floating Style Screw-In Cartridge

- Sun Model Code Explanation; 999-901-334

- Custom Integrated Packages from Sun

Notes:

- Some applications may require additional volume for a smoother shift. Should this become necessary, an auxillary port has been provided to attach a length of hose for additional volume.

- Important: Carefully consider the maximum system pressure. The pressure rating of the manifold is dependent on the manifold material, with the port type/size a secondary consideration. Manifolds constructed of aluminum are not rated for pressures higher than 3000 psi (210 bar), regardless of the port type/size specified.