SUN HYDRAULICS

XRDCLNNHO

$429.70 USD

Tags:

- SUN HYDRAULICS

- Material:XRDCLNNHO

- Model:XRDC-LNN-HO

- Summary:Y-assembly

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

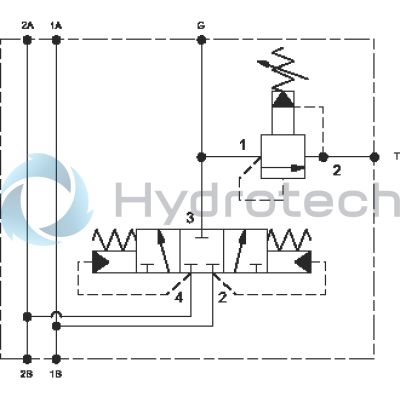

The Sun Hydraulics XRDCLNNHO (Material Number: XRDCLNNHO) is a specialized valve assembly designed to enhance the performance of hydrostatic transmissions through an efficient hot oil flushing circuit. This mechanism facilitates the removal of hot, contaminated oil from the low-pressure side of the loop, replacing it with cooler, filtered oil via the charge pump. The flushed hot oil can also pass through the cases of both the pump and motor, ensuring that they are free from heat and debris. A notable feature of this assembly is its ability to allow for confirmation or adjustment of the hot oil relief setting when the transmission is in neutral, providing operational flexibility. The design includes common ports marked as 1 and 2, allowing for easy integration into existing systems by teeing off rather than direct plumbing into the loop. The high-pressure relief on one side controls pressure on the opposite port, making it a versatile component in managing system dynamics. When in neutral, charge pressure is regulated by the charge pump relief; however, upon activation of the hot oil shuttle, flow redirection occurs to manage temperature effectively. With a standard hot oil relief setting at 200 psi (14 bar) at a flow rate of 4 gpm (16 L/min), this valve assembly supports capacities up to 10 gpm (40 L/min). It is designed for line mounting with four mounting holes for secure installation. Given hydraulic motors' tendency to leak slightly over time, incorporating a mechanical brake is advisable for positively locking any stopped live loads. The manifold's construction from corrosion-resistant 6061-T651 aluminum ensures durability without anodizing, maintaining its integrity under typical operating conditions while avoiding additional costs associated with anodization processes.

The Sun Hydraulics XRDCLNNHO (Material Number: XRDCLNNHO) is a specialized valve assembly designed to enhance the performance of hydrostatic transmissions through an efficient hot oil flushing circuit. This mechanism facilitates the removal of hot, contaminated oil from the low-pressure side of the loop, replacing it with cooler, filtered oil via the charge pump. The flushed hot oil can also pass through the cases of both the pump and motor, ensuring that they are free from heat and debris. A notable feature of this assembly is its ability to allow for confirmation or adjustment of the hot oil relief setting when the transmission is in neutral, providing operational flexibility. The design includes common ports marked as 1 and 2, allowing for easy integration into existing systems by teeing off rather than direct plumbing into the loop. The high-pressure relief on one side controls pressure on the opposite port, making it a versatile component in managing system dynamics. When in neutral, charge pressure is regulated by the charge pump relief; however, upon activation of the hot oil shuttle, flow redirection occurs to manage temperature effectively. With a standard hot oil relief setting at 200 psi (14 bar) at a flow rate of 4 gpm (16 L/min), this valve assembly supports capacities up to 10 gpm (40 L/min). It is designed for line mounting with four mounting holes for secure installation. Given hydraulic motors' tendency to leak slightly over time, incorporating a mechanical brake is advisable for positively locking any stopped live loads. The manifold's construction from corrosion-resistant 6061-T651 aluminum ensures durability without anodizing, maintaining its integrity under typical operating conditions while avoiding additional costs associated with anodization processes.

This valve assembly provides a flushing circuit for hydrostatic transmissions. The hot oil flushing circuit allows a discharge of oil from the low pressure side of the loop. The charge pump replaces the hot, dirty oil with cool, filtered oil. The hot oil discharge is often passed through the cases of the pump and the motor, flushing hot, dirty oil from them as well.

- A unique feature of the hot oil shuttle is that the setting of the hot oil relief can be confirmed or adjusted when the transmission is in neutral.

- The two ports marked 1 are common as are the two marked 2. Therefore the assembly can be teed off the loop rather than being plumbed into the loop.

- The two ports marked 1 are common as are the two marked 2. The high pressure relief that is physically on the same side as port 1 controls the pressure on port 2 and vice versa.

- When the transmission is in neutral the charge pressure is controlled by the charge pump relief. When the hot oil shuttle opens, some or all of the charge pump flow is redirected to the hot oil relief. The charge pump relief must be set higher than the hot oil relief to produce hot oil flow. The higher the differential pressure between the 2 reliefs, the higher the hot oil flow. The amount of hot oil flow is determined by the pressure vrs flow curves of the 2 reliefs and is difficult to quantify.

- The standard setting of the hot oil relief is 200 psi (14 bar) at a flow of 4 gpm (16 L/min).

- Hydraulic motors leak. Therefore a mechanical brake is recommended to positively lock any stopped live load.

| Capacity | 10 gpm40 L/min. |

| Body Type | Line mountLine mount |

| Mounting Hole Quantity | 44 |

Show FAQ

Additional Resources

- Protect Hydrostatic Transmission Circuits with Sun’s Delayed Shift Hot Oil Shuttle.

- Integrated Packages: Solutions That Grow Your Reputation

- Manufacturing Sun Cartridge Cavities

- Sun's Floating Style Screw-In Cartridge

- Sun Model Code Explanation; 999-901-334

- Custom Integrated Packages from Sun

- Fluid and Temperature Recommendations

Notes:

- Important: Carefully consider the maximum system pressure. The pressure rating of the manifold is dependent on the manifold material, with the port type/size a secondary consideration. Manifolds constructed of aluminum are not rated for pressures higher than 3000 psi (210 bar), regardless of the port type/size specified.