SUN HYDRAULICS

WRL

$301.90 USD

Tags:

- SUN HYDRAULICS

- Material:WRL

- Summary:Manifold

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

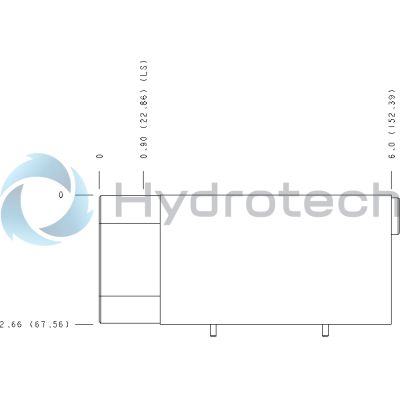

The Sun Hydraulics WRL (Material Number: WRL) is a sandwich manifold designed with an ISO 07 interface and features on A to T, port 3 to B. The manifold has a stack height of 2.74 inches (70 mm) and accommodates open cavities with a T-17A cavity type. It is equipped with 1/4 BSPP port sizes, making it compatible with various hydraulic configurations. This manifold body is used in hydraulic systems where modular stacking of directional control valves is required, allowing for compact system design and efficient fluid flow management. The WRL model's unique design ensures easy integration into existing systems while maintaining optimal performance in controlling fluid direction and pressure within the circuit. Its construction from 6061-T651 aluminum provides excellent corrosion resistance and strength, suitable for environments where these factors are critical. Additionally, the sandwich manifold's design includes specific boss profiles, which facilitate consistent alignment during assembly and contribute to its aesthetically pleasing appearance when stacked with other manifolds. This model does not require anodizing due to the inherent properties of the aluminum used, which supports its durability without additional surface treatment processes that could impact fatigue life or increase costs. When assembling a stack of sandwich valves using this manifold, it is crucial to maintain dry o-ring sealing surfaces to prevent hydraulic fluid leakage through the pressurized port interfaces.

The Sun Hydraulics WRL (Material Number: WRL) is a sandwich manifold designed with an ISO 07 interface and features on A to T, port 3 to B. The manifold has a stack height of 2.74 inches (70 mm) and accommodates open cavities with a T-17A cavity type. It is equipped with 1/4 BSPP port sizes, making it compatible with various hydraulic configurations. This manifold body is used in hydraulic systems where modular stacking of directional control valves is required, allowing for compact system design and efficient fluid flow management. The WRL model's unique design ensures easy integration into existing systems while maintaining optimal performance in controlling fluid direction and pressure within the circuit. Its construction from 6061-T651 aluminum provides excellent corrosion resistance and strength, suitable for environments where these factors are critical. Additionally, the sandwich manifold's design includes specific boss profiles, which facilitate consistent alignment during assembly and contribute to its aesthetically pleasing appearance when stacked with other manifolds. This model does not require anodizing due to the inherent properties of the aluminum used, which supports its durability without additional surface treatment processes that could impact fatigue life or increase costs. When assembling a stack of sandwich valves using this manifold, it is crucial to maintain dry o-ring sealing surfaces to prevent hydraulic fluid leakage through the pressurized port interfaces.

| Body Type | SandwichSandwich |

| Interface | ISO 07ISO 07 |

| Body Features | On A to T, port 3 to BOn A to T, port 3 to B |

| Stack Height | 2.74 in.70 mm |

| Open Cavities | 11 |

| Cavity | T-17A |

| Port Size | 1/4" BSPP1/4" BSPP |

Show FAQ

Additional Resources

- QuickDesign with SmartConnect Offers Drag-and-Drop Schematic Tool

- Sun Sandwich Bodies Interchangeable with Bosch and Others

- Manufacturing Sun Cartridge Cavities

- Mounting and Assembly of Sandwich Bodies

- Custom Integrated Packages from Sun

- QuickDesign & SunDesign: Sun's 3- & 5-Axis Solutions

- Manifolds: Materials of Construction

- Sun's Floating Style Screw-In Cartridge

- Sun Model Code Explanation; 999-901-334

- Fluid and Temperature Recommendations

Notes:

- Important: Carefully consider the maximum system pressure. The pressure rating of the manifold is dependent on the manifold material, with the port type/size a secondary consideration. Manifolds constructed of aluminum are not rated for pressures higher than 3000 psi (210 bar), regardless of the port type/size specified.