SUN HYDRAULICS

RSJSKBN

$528.50 USD

Tags:

- SUN HYDRAULICS

- Material:RSJSKBN

- Model:RSJS-KBN

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

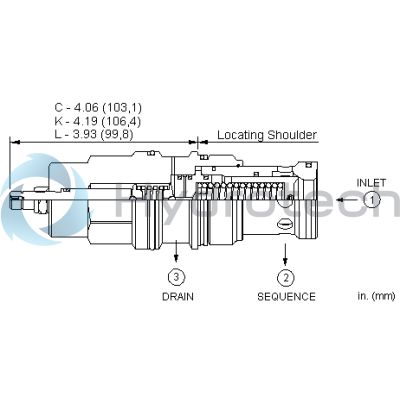

The Sun Hydraulics RSJSKBN (RSJSKBN) is a pilot-operated, balanced poppet sequence valve designed to supply a secondary circuit with flow once the inlet pressure at port 1 exceeds the valve setting. This valve is engineered to control pressure at port 1 relative to the drain port 3, and it remains unaffected by back pressure at port 2 up to the valve setting. It can replace 2-port relief valves in systems with return line pressure and is compatible with cross-port relief circuits. The RSJSKBN features interchangeable functionality across all 3-port sequence cartridges, ensuring consistent flow paths and cavity compatibility for a given frame size. The valve's pilot flow increases as the inlet pressure at port 1 surpasses the drain pressure at port 3 beyond the set point, with protection provided by a main stage orifice shielded by a 150-micron stainless steel screen. The pressure at port 3 directly adds to the valve setting on a one-to-one basis, not exceeding 5000 psi (350 bar). Internal modulation within the cartridge makes these valves resistant to cavitation issues such as noise and manifold erosion. The Sun floating style construction minimizes internal binding risks due to excessive installation torque or machining variations. With a capacity of up to 120 gpm (480 L/min), maximum operating pressure of 5000 psi (350 bar), and typical response time of just 2 ms, this robust component offers reliable performance in demanding hydraulic applications. The RSJSKBN model includes an adjustment mechanism for increasing settings via clockwise turns, complemented by specific torque requirements for installation and locknut adjustments. Additionally, it comes equipped with Viton seals for enhanced durability in various operational conditions.

The Sun Hydraulics RSJSKBN (RSJSKBN) is a pilot-operated, balanced poppet sequence valve designed to supply a secondary circuit with flow once the inlet pressure at port 1 exceeds the valve setting. This valve is engineered to control pressure at port 1 relative to the drain port 3, and it remains unaffected by back pressure at port 2 up to the valve setting. It can replace 2-port relief valves in systems with return line pressure and is compatible with cross-port relief circuits. The RSJSKBN features interchangeable functionality across all 3-port sequence cartridges, ensuring consistent flow paths and cavity compatibility for a given frame size. The valve's pilot flow increases as the inlet pressure at port 1 surpasses the drain pressure at port 3 beyond the set point, with protection provided by a main stage orifice shielded by a 150-micron stainless steel screen. The pressure at port 3 directly adds to the valve setting on a one-to-one basis, not exceeding 5000 psi (350 bar). Internal modulation within the cartridge makes these valves resistant to cavitation issues such as noise and manifold erosion. The Sun floating style construction minimizes internal binding risks due to excessive installation torque or machining variations. With a capacity of up to 120 gpm (480 L/min), maximum operating pressure of 5000 psi (350 bar), and typical response time of just 2 ms, this robust component offers reliable performance in demanding hydraulic applications. The RSJSKBN model includes an adjustment mechanism for increasing settings via clockwise turns, complemented by specific torque requirements for installation and locknut adjustments. Additionally, it comes equipped with Viton seals for enhanced durability in various operational conditions.

Pilot-operated, balanced poppet sequence valves will supply a secondary circuit with flow once the pressure at the inlet (port 1) has exceeded the valve setting. The pressure setting of a sequence valve controls the pressure at port 1 relative to the pressure at the drain (port 3). These valves are insensitive to back pressure at port 2 (sequence), up to the valve setting. They may be used to regulate pressure in place of 2-port relief valves if there is pressure in the return line.

- All 3 port sequence cartridges are physically and functionally interchangeable (i.e. same flow path, same cavity for a given frame size).

- Pilot flow continues to increase as the pressure at port 1 (inlet), relative to the pressure at port 3 (drain), rises above the valve setting.

- The main stage orifice is protected by a 150 micron stainless steel screen.

- Pressure at port 3 is directly additive to the valve setting at a 1:1 ratio and should not exceed 5000 psi (350 bar).

- Because the modulating occurs inside the cartridge these valves are immune to most of the problems associated with cavitation, namely noise and manifold erosion.

- Will accept maximum pressure at port 2; suitable for use in cross port relief circuits.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-19A |

| Series | 4 |

| Capacity | 120 gpm480 L/min. |

| Factory Pressure Settings Established at | 4 gpm15 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Control Pilot Flow | 15 - 20 in³/min.0,25 - 0,33 L/min. |

| Response Time - Typical | 2 ms2 ms |

| Maximum Valve Leakage at Reseat | 10 drops/min.0,7 cc/min. |

| Adjustment - Number of Clockwise Turns to Increase Setting | 55 |

| Valve Hex Size | 1 5/8 in.41,3 mm |

| Valve Installation Torque | 350 - 375 lbf ft474 - 508 Nm |

| Adjustment Screw Internal Hex Size | 5/32 in.4 mm |

| Locknut Hex Size | 9/16 in.15 mm |

| Locknut Torque | 80 - 90 lbf in.9 - 10 Nm |

| Model Weight | 3.10 lb1,40 kg |

| Seal kit - Cartridge | Viton: 990-219-006 |

Show FAQ

Additional Resources

- Sun Offers Zinc-Nickel Plating for Corrosion Resistance

- Sun Cartridges with EPDM Seals

- Sun Expands Corrosion-Resistant Solutions

- QuickDesign with SmartConnect Offers Drag-and-Drop Schematic Tool

- Series 4 PLUS Cartridges Offer Higher Flows with Lower Pressure Losses

- Sequence Valves Technical Tips

- Manufacturing Sun Cartridge Cavities

- Sequence Valves

- Sun Model Code Explanation; 999-901-334

- Cavity Information (S-171) and Tooling

- Cartridges: Materials of Construction

- Fluid and Temperature Recommendations

- Performance Data

- Sun's Floating Style Screw-In Cartridge

- Units of Measure, Settings, and Conversions