SUN HYDRAULICS

RPKSKNN

$447.70 USD

Tags:

- SUN HYDRAULICS

- Material:RPKSKNN

- Model:RPKS-KNN

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

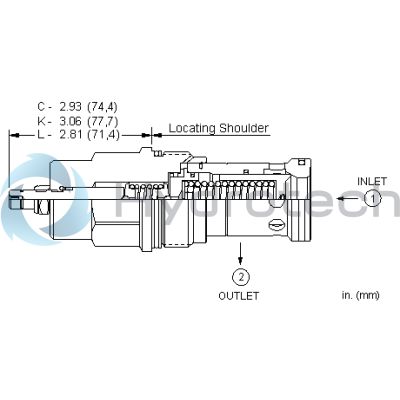

The Sun Hydraulics RPKSKNN (RPKSKNN) is a pilot-operated, balanced-poppet relief cartridge designed to function as a pressure regulating valve. This normally closed valve begins to open when the inlet port 1 reaches the preset pressure, allowing flow to the tank port 2 to maintain regulated pressure. Notably accurate and smooth, these valves operate quietly and quickly with minimal pressure rise relative to flow. The internal modulating mechanism makes them resistant to cavitation-related issues such as noise and manifold erosion. Capable of handling maximum pressure at port 2, they are ideal for cross-port relief circuits and remain stable despite variations in oil temperature or contamination. The main stage orifice is safeguarded by a 150-micron stainless steel screen, and backpressure on tank port 2 directly influences the valve setting at a 1:1 ratio. Adjustable via W or Y controls, these valves can be specified with or without special settings for maximum adjustability. Corrosion-resistant versions are available with external components made of stainless steel (suffix AP) or zinc-nickel plated (suffix LH). The Sun floating style construction minimizes binding risks due to installation torque or machining variations. With a cavity size of T-18A Series 4 and a capacity of 200 gpm (760 L/min), this cartridge valve operates up to a maximum pressure of 5000 psi (350 bar), typically responding within 7 milliseconds. It features minimal leakage at reseat with only up to 10 drops/minute (0.7 cc/min). Installation requires a torque of 350-375 lbf ft (474-508 Nm), while adjustments need an internal hex size of 5/32 inches (4 mm). The model weighs approximately 2.50 lb (1.15 kg) and uses Viton seal kits for optimal performance in various applications, including scenarios requiring quick response relief mechanisms like portable grain augers for silos.

The Sun Hydraulics RPKSKNN (RPKSKNN) is a pilot-operated, balanced-poppet relief cartridge designed to function as a pressure regulating valve. This normally closed valve begins to open when the inlet port 1 reaches the preset pressure, allowing flow to the tank port 2 to maintain regulated pressure. Notably accurate and smooth, these valves operate quietly and quickly with minimal pressure rise relative to flow. The internal modulating mechanism makes them resistant to cavitation-related issues such as noise and manifold erosion. Capable of handling maximum pressure at port 2, they are ideal for cross-port relief circuits and remain stable despite variations in oil temperature or contamination. The main stage orifice is safeguarded by a 150-micron stainless steel screen, and backpressure on tank port 2 directly influences the valve setting at a 1:1 ratio. Adjustable via W or Y controls, these valves can be specified with or without special settings for maximum adjustability. Corrosion-resistant versions are available with external components made of stainless steel (suffix AP) or zinc-nickel plated (suffix LH). The Sun floating style construction minimizes binding risks due to installation torque or machining variations. With a cavity size of T-18A Series 4 and a capacity of 200 gpm (760 L/min), this cartridge valve operates up to a maximum pressure of 5000 psi (350 bar), typically responding within 7 milliseconds. It features minimal leakage at reseat with only up to 10 drops/minute (0.7 cc/min). Installation requires a torque of 350-375 lbf ft (474-508 Nm), while adjustments need an internal hex size of 5/32 inches (4 mm). The model weighs approximately 2.50 lb (1.15 kg) and uses Viton seal kits for optimal performance in various applications, including scenarios requiring quick response relief mechanisms like portable grain augers for silos.

Pilot-operated, balanced-poppet relief cartridges are normally closed pressure regulating valves. When the pressure at the inlet (port 1) reaches the valve setting, the valve starts to open to tank (port 2), throttling flow to regulate the pressure. These valves are accurate, smooth, quiet, fast, and have low pressure rise vs. flow.

- Because the modulating occurs inside the cartridge, these valves are immune to most of the problems associated with cavitation, namely noise and manifold erosion.

- Will accept maximum pressure at port 2; suitable for use in cross port relief circuits.

- Valve is relatively insensitive to varying oil temperatures and oil borne contamination.

- Main stage orifice is protected by a 150 micron stainless steel screen.

- Back pressure on the tank port (port 2) is directly additive to the valve setting at a 1:1 ratio.

- W and Y controls (where applicable) can be specified with or without a special setting. When no special setting is specified, the valve is adjustable throughout its full range using the W or Y control. When a special setting is specified, this setting represents the maximum setting of the valve.

- Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP for external stainless steel components, or /LH for external zinc-nickel plated components. See the CONFIGURATION section for all options. For further details, please see the Materials of Construction page located under TECH RESOURCES.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-18A |

| Series | 4 |

| Capacity | 200 gpm760 L/min. |

| Factory Pressure Settings Established at | 4 gpm15 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Response Time - Typical | 7 ms7 ms |

| Maximum Valve Leakage at Reseat | 10 drops/min.0,7 cc/min. |

| Adjustment - Number of Clockwise Turns to Increase Setting | 55 |

| Valve Hex Size | 1 5/8 in.41,3 mm |

| Valve Installation Torque | 350 - 375 lbf ft474 - 508 Nm |

| Adjustment Screw Internal Hex Size | 5/32 in.4 mm |

| Locknut Hex Size | 9/16 in.15 mm |

| Locknut Torque | 80 - 90 lbf in.9 - 10 Nm |

| Model Weight | 2.50 lb1,15 kg |

| Seal kit - Cartridge | Viton: 990-318-006 |

Show FAQ

Additional Resources

- Tri-Grip Handknob Now Offered From Sun as a Standard Control Option

- QuickDesign with SmartConnect Offers Drag-and-Drop Schematic Tool

- Sun Introduces 'Hybrid' Valves

- CE/TÜV Certified Pressure Relief Valves

- Pressure Relief and Regulating Cartridge Valve Technical Tips

- Pilot Operated, Balanced Poppet Relief Valves

- Sun Expands Corrosion-Resistant Solutions

- Sun Offers Zinc-Nickel Plating for Corrosion Resistance

- Sun Cartridges with EPDM Seals

- Series 4 PLUS Cartridges Offer Higher Flows with Lower Pressure Losses

- Pilot-Operated, Balanced Poppet, Anti Shock Reliefs

- CavitySaver multi-function valves deliver single-cartridge solutions

- 'Soft' Relief Eliminates Pressure Spikes

- Manufacturing Sun Cartridge Cavities

- Pressure Relief and Regulating Valves

- Cavity Information (S-171) and Tooling

- Sun Model Code Explanation; 999-901-334

- Cartridges: Materials of Construction

- Fluid and Temperature Recommendations

- Performance Data

- Sun's Floating Style Screw-In Cartridge

- Units of Measure, Settings, and Conversions