SUN HYDRAULICS

RBACLBN/LH

$90.80 USD

Tags:

- SUN HYDRAULICS

- Material:RBACLBN/LH

- Model:RBAC-LBN/LH

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

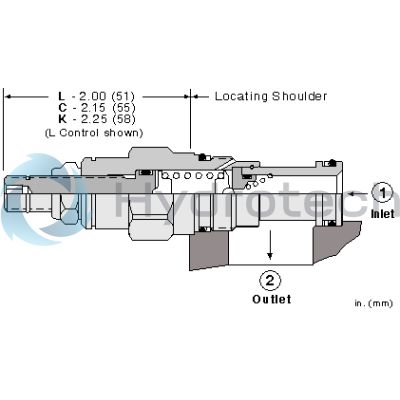

The Sun Hydraulics RBACLBN/LH (RBACLBN/LH) is a direct-acting, pilot relief cartridge valve designed for precise pressure control in hydraulic systems. This valve is specifically used to remotely control the pressure setting of other pilot-operated valves, making it ideal for applications where capacity is limited to pilot flow and higher flow valves are required for primary operation. Notably, the RBACLBN/LH model features EPDM seals, suitable for use with phosphate ester fluids, while being incompatible with petroleum-based fluids. The main stage orifice is safeguarded by a 150-micron stainless steel screen, ensuring optimal performance in load-holding applications. This model is corrosion-resistant, featuring external zinc-nickel plated components identified by the LH suffix in its model code. It incorporates Sun's floating style construction to minimize internal part binding due to excessive installation torque or machining variations. The valve has a cavity size of T-10A Series 1 and a capacity of 0.25 gpm (1 L/min), with a maximum operating pressure of 5000 psi (350 bar). Its response time is typically 2 ms, and it allows for an adjustment range through clockwise turns to increase the setting up to five times. The RBACLBN/LH valve's design also includes specific installation requirements: a valve hex size of 7/8 inch (22.2 mm) and an installation torque range between 30 - 35 lbf ft (41 - 47 Nm). Additionally, this model comes with a seal kit option in Viton material coded as 990010006, ensuring compatibility with various system requirements. The Sun Hydraulics RBACLBN/LH valve provides reliable and robust performance for controlling hydraulic pressures efficiently within specified applications.

The Sun Hydraulics RBACLBN/LH (RBACLBN/LH) is a direct-acting, pilot relief cartridge valve designed for precise pressure control in hydraulic systems. This valve is specifically used to remotely control the pressure setting of other pilot-operated valves, making it ideal for applications where capacity is limited to pilot flow and higher flow valves are required for primary operation. Notably, the RBACLBN/LH model features EPDM seals, suitable for use with phosphate ester fluids, while being incompatible with petroleum-based fluids. The main stage orifice is safeguarded by a 150-micron stainless steel screen, ensuring optimal performance in load-holding applications. This model is corrosion-resistant, featuring external zinc-nickel plated components identified by the LH suffix in its model code. It incorporates Sun's floating style construction to minimize internal part binding due to excessive installation torque or machining variations. The valve has a cavity size of T-10A Series 1 and a capacity of 0.25 gpm (1 L/min), with a maximum operating pressure of 5000 psi (350 bar). Its response time is typically 2 ms, and it allows for an adjustment range through clockwise turns to increase the setting up to five times. The RBACLBN/LH valve's design also includes specific installation requirements: a valve hex size of 7/8 inch (22.2 mm) and an installation torque range between 30 - 35 lbf ft (41 - 47 Nm). Additionally, this model comes with a seal kit option in Viton material coded as 990010006, ensuring compatibility with various system requirements. The Sun Hydraulics RBACLBN/LH valve provides reliable and robust performance for controlling hydraulic pressures efficiently within specified applications.

Direct-acting, pilot relief cartridges are used to remotely control the pressure setting of other pilot-operated valves. Because capacity is limited to pilot flow, these valves should be used with other higher flow valves.

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- Main stage orifice is protected by a 150 micron stainless steel screen.

- Suitable for use in load holding applications.

- Back pressure on the tank port (port 2) is directly additive to the valve setting at a 1:1 ratio.

- W and Y controls (where applicable) can be specified with or without a special setting. When no special setting is specified, the valve is adjustable throughout its full range using the W or Y control. When a special setting is specified, this setting represents the maximum setting of the valve.

- Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP for external stainless steel components, or /LH for external zinc-nickel plated components. See the CONFIGURATION section for all options. For further details, please see the Materials of Construction page located under TECH RESOURCES.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-10A |

| Series | 1 |

| Capacity | .25 gpm1 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Response Time - Typical | 2 ms2 ms |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 5 drops/min.0,3 cc/min. |

| Adjustment - Number of Clockwise Turns to Increase Setting | 55 |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Adjustment Screw Internal Hex Size | 5/32 in.4 mm |

| Locknut Hex Size | 9/16 in.15 mm |

| Locknut Torque | 80 - 90 lbf in.9 - 10 Nm |

| Model Weight | .30 lb0,15 kg |

| Seal kit - Cartridge | Viton: 990-010-006 |

Show FAQ

Additional Resources

- Pilot-Operated, Balanced Poppet, Anti Shock Reliefs

- CavitySaver multi-function valves deliver single-cartridge solutions

- 'Soft' Relief Eliminates Pressure Spikes

- Tri-Grip Handknob Now Offered From Sun as a Standard Control Option

- QuickDesign with SmartConnect Offers Drag-and-Drop Schematic Tool

- Sun Introduces 'Hybrid' Valves

- CE/TÜV Certified Pressure Relief Valves

- Pressure Relief and Regulating Cartridge Valve Technical Tips

- Pilot Operated, Balanced Poppet Relief Valves

- Sun Expands Corrosion-Resistant Solutions

- Sun Offers Zinc-Nickel Plating for Corrosion Resistance

- Sun Cartridges with EPDM Seals

- Series 4 PLUS Cartridges Offer Higher Flows with Lower Pressure Losses

- Manufacturing Sun Cartridge Cavities

- Pressure Relief and Regulating Valves

- Sun's Floating Style Screw-In Cartridge

- Units of Measure, Settings, and Conversions

- Cavity Information (S-171) and Tooling

- Sun Model Code Explanation; 999-901-334

- Cartridges: Materials of Construction

- Fluid and Temperature Recommendations

- Performance Data

Notes:

- For Series 1 cartridges configured with an O control (panel mount handknob), a .75 in. (19 mm) diameter hole is required in the panel.