SUN HYDRAULICS

HDDADCV912N

$193.70 USD

Tags:

- SUN HYDRAULICS

- Material:HDDADCV912N

- Model:HDDA-DCV@912N

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics HDDADCV912N (HDDADCV912N) is a versatile solenoid-after check cartridge valve designed for lift-lower applications and can be seamlessly integrated into actuators. This hybrid valve features a direct-acting solenoid poppet valve connected after the check function, allowing flow from inlet port 2 to system port 1 while blocking flow from port 2 to port 3 when the solenoid is de-energized. It is particularly suitable for load-holding applications and utilizes a wet armature design, where the working fluid surrounds the armature, exposing it to coil-generated heat. This design consideration is crucial when using fluids like water-glycol mixtures that may degrade under prolonged heat exposure. The valve's robust construction includes a fatigue-rated solenoid tube assembly capable of handling up to 5000 psi (350 bar), ensuring durability and reliability in demanding conditions. It offers several manual override choices, although manual override functionality is incompatible with weatherized coils. The manual control assembly has an estimated mechanical life expectancy of approximately 7,000 cycles and requires a force of 5 lbs/1000 psi at Port 1 for actuation. With interchangeable coils compatible with other Sun Series 1 solenoid products, installation flexibility is enhanced as coils can be mounted in either direction on the tube. Coil connector options provide ratings up to IP69K for superior environmental protection, and additional weatherized coils and kits are available for enhanced durability in harsh conditions. The valve incorporates Sun's floating style construction to minimize internal part binding due to excessive installation torque or machining variations, ensuring reliable performance. With a capacity of up to 10 gpm (40 L/min) and a response time of about 50 ms, this cartridge offers efficient operation across various settings.

The Sun Hydraulics HDDADCV912N (HDDADCV912N) is a versatile solenoid-after check cartridge valve designed for lift-lower applications and can be seamlessly integrated into actuators. This hybrid valve features a direct-acting solenoid poppet valve connected after the check function, allowing flow from inlet port 2 to system port 1 while blocking flow from port 2 to port 3 when the solenoid is de-energized. It is particularly suitable for load-holding applications and utilizes a wet armature design, where the working fluid surrounds the armature, exposing it to coil-generated heat. This design consideration is crucial when using fluids like water-glycol mixtures that may degrade under prolonged heat exposure. The valve's robust construction includes a fatigue-rated solenoid tube assembly capable of handling up to 5000 psi (350 bar), ensuring durability and reliability in demanding conditions. It offers several manual override choices, although manual override functionality is incompatible with weatherized coils. The manual control assembly has an estimated mechanical life expectancy of approximately 7,000 cycles and requires a force of 5 lbs/1000 psi at Port 1 for actuation. With interchangeable coils compatible with other Sun Series 1 solenoid products, installation flexibility is enhanced as coils can be mounted in either direction on the tube. Coil connector options provide ratings up to IP69K for superior environmental protection, and additional weatherized coils and kits are available for enhanced durability in harsh conditions. The valve incorporates Sun's floating style construction to minimize internal part binding due to excessive installation torque or machining variations, ensuring reliable performance. With a capacity of up to 10 gpm (40 L/min) and a response time of about 50 ms, this cartridge offers efficient operation across various settings.

This solenoid-after check cartridge is a hybrid valve incorporating a direct acting solenoid poppet valve teed in after the check function. The check valve flow is from the inlet (port 2) to the system (port 1). With the solenoid de-energized flow from (port 2) to (port 3) is blocked. This combination valve is typically used in lift/lower applications and can be integrated directly into the actuator.

- The solenoid tube assembly is fatigue rated for 5000 psi (350 bar) service.

- On models equipped with the D or L control, the detent mechanism in the manual override is meant for temporary actuation. The D, L and T manual control assembly has a mechanical life expectancy of approximately 7,000 cycles.

- This cartridge has several manual override choices, including no manual override. See the CONFIGURATION section. Please note: Manual override functionality is not compatible with weatherized coils.

- Suitable for load holding applications.

- This valve utilizes a wet armature design. This means that the working fluid surrounds the armature and is exposed to the heat generated by the coil. This can be a factor if the coil is energized for long periods of time. Some fluids, notably water/glycol mixtures, break down at these temperatures over time and form varnishes that will affect the function of the cartridge.

- Coils are interchangeable with other Sun Series 1 solenoid products and can be mounted on the tube in either direction.

- Coil connector options offer ratings up to IP69K. See individual coil product pages for details. Additional weatherized coils and kits are available for more complete environmental protection.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-11A |

| Series | 1 |

| Capacity | 10 gpm40 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Response Time - Typical | 50 ms50 ms |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 10 drops/min.@5000 psi0,7 cc/min.@350 bar |

| Check Cracking Pressure | 30 psi2 bar |

| Switching Frequency | 15000 cycles/hr15000 cycles/hr |

| Manual Override Force Requirement | 5 lbs/1000 psi @ Port 133 N/100 bar @ Port 1 |

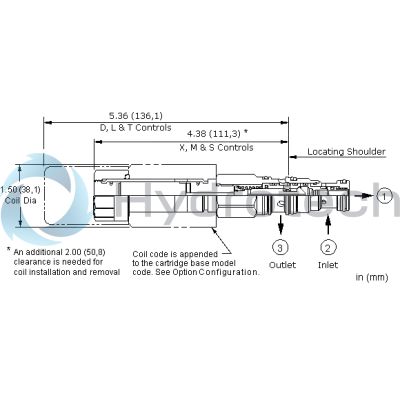

| Manual Override Stroke | .10 in.2,5 mm |

| Solenoid Tube Diameter | .75 in.19 mm |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Seal kit - Cartridge | Viton: 990-011-006 |

| Seal and nut kit - Coil | Viton: 990-770-006Viton: 990-770-006 |

Show FAQ