SUN HYDRAULICS

FTHCXYN

$815.50 USD

Tags:

- SUN HYDRAULICS

- Material:FTHCXYN

- Model:FTHC-XYN

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics FTHCXYN (FTHCXYN) is a 4-way, 3-position proportional directional valve designed for precise flow control applications. In its center position, work ports 2 and 4 are drained to port 5, while port 3 remains closed. The valve operates by using pilot pressure at port 1 to counteract the spring force, creating a variable metering orifice between ports 3 and 4 that adjusts proportionally to the pressure at port 1. Additionally, piloting port 6 opens the connection between ports 3 and 2. This valve offers partial self-compensation due to the balance of flow forces, spring tension, and pilot pressure as load pressures fluctuate. The FTHCXYN valve can be externally pressure compensated using modulating logic elements such as LRCXHN for bypass circuits or LPCXHN for restrictive circuits. This feature enhances flow control accuracy over a broader range of flows and pressures. The maximum pilot pressure at ports 1 and 6 should not exceed 500 psi (35 bar), with these two ports directly opposing each other in function. Constructed with Sun's floating style design, this valve minimizes the risk of internal parts binding due to excessive installation torque or variations in cavity/cartridge machining. It fits into a T-54A cavity and belongs to series 4 with a capacity of up to 80 gpm (320 L/min). The minimum pilot pressure required to shift the valve is set at 80 psi (5.5 bar), while its maximum operating pressure reaches up to 5000 psi (350 bar). Valve leakage is minimal at specified conditions, ensuring efficient operation. With a hysteresis of \u00b12%, this valve maintains stability under varying operational demands. Installation requires a torque specification between 350 -375 lbf ft (475 -508 Nm), and it uses Viton seal kits for optimal sealing performance.

The Sun Hydraulics FTHCXYN (FTHCXYN) is a 4-way, 3-position proportional directional valve designed for precise flow control applications. In its center position, work ports 2 and 4 are drained to port 5, while port 3 remains closed. The valve operates by using pilot pressure at port 1 to counteract the spring force, creating a variable metering orifice between ports 3 and 4 that adjusts proportionally to the pressure at port 1. Additionally, piloting port 6 opens the connection between ports 3 and 2. This valve offers partial self-compensation due to the balance of flow forces, spring tension, and pilot pressure as load pressures fluctuate. The FTHCXYN valve can be externally pressure compensated using modulating logic elements such as LRCXHN for bypass circuits or LPCXHN for restrictive circuits. This feature enhances flow control accuracy over a broader range of flows and pressures. The maximum pilot pressure at ports 1 and 6 should not exceed 500 psi (35 bar), with these two ports directly opposing each other in function. Constructed with Sun's floating style design, this valve minimizes the risk of internal parts binding due to excessive installation torque or variations in cavity/cartridge machining. It fits into a T-54A cavity and belongs to series 4 with a capacity of up to 80 gpm (320 L/min). The minimum pilot pressure required to shift the valve is set at 80 psi (5.5 bar), while its maximum operating pressure reaches up to 5000 psi (350 bar). Valve leakage is minimal at specified conditions, ensuring efficient operation. With a hysteresis of \u00b12%, this valve maintains stability under varying operational demands. Installation requires a torque specification between 350 -375 lbf ft (475 -508 Nm), and it uses Viton seal kits for optimal sealing performance.

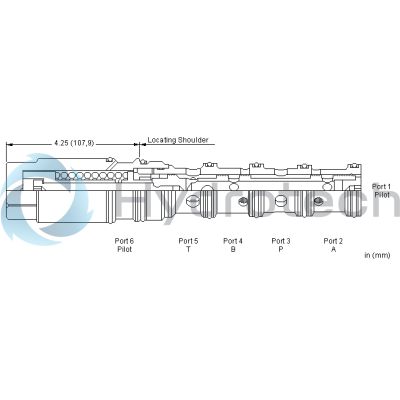

This valve is a 4-way, 3 position, proportional directional valve. Work ports 2 and 4 are drained to 5 in the center position and port 3 is closed. Pilot pressure at port 1 opposes the spring and creates a variable metering orifice between ports 3 and 4 that is proportional to the pressure at 1. Piloting 6 opens 3 to 2. The force balance of the flow forces, spring and pilot pressure results in a degree of partial self compensation as the load pressure changes.

Pressure at ports 1 and 6 directly oppose each other.

- Maximum pilot pressure for ports 1 and 6 should not exceed 500 psi (35 bar).

- These valves may be pressure compensated by an external, modulating, logic element. Use LR_C-XHN for a bypass circuit or LP_C-XHN for a restrictive circuit.

- The valve provides a degree of self-compensation and may be used as a flow control. To increase the accuracy of flow control, an external, modulating, logic element can be used to maintain a constant flow over a wider range of flows and pressures. See performance curves for additional information.

- Pressure at ports 1 and 6 directly oppose each other.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-54A |

| Series | 4 |

| Capacity | 80 gpm320 L/min. |

| Minimum Pilot Pressure Required to Shift Valve | 80 psi5,5 bar |

| Maximum Operating Pressure | 5000 psi350 bar |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 5 in³/min.@1000 psi80 cc/min.@70 bar |

| Pilot Volume Displacement | .26 in³4,3 cc |

| Maximum Pilot Pressure | 500 psi35 bar |

| Hysteresis | ± 2 %± 2 % |

| Valve Hex Size | 1 5/8 in.41,3 mm |

| Valve Installation Torque | 350 - 375 lbf ft475 - 508 Nm |

| Seal kit - Cartridge | Viton: 990-054-006 |

Show FAQ