SUN HYDRAULICS

FSCHXAN

$170.30 USD

Tags:

- SUN HYDRAULICS

- Material:FSCHXAN

- Model:FSCH-XAN

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics FSCHXAN (FSCHXAN) is a high-capacity, closed-center flow divider-combiner designed for tractive drive systems. This sliding-spool, pressure-compensated device efficiently splits flow in one direction and combines it in the opposite direction, offering approximately 15% greater capacity than standard models. It features a T31A cavity and Series 1 configuration, with a capacity range of 2 to 9 gpm (8 to 34 L/min) and a maximum operating pressure of 5000 psi (350 bar). The valve's divisional accuracy at minimum input flow is 50 \u00b16.5%, improving to \u00b13.5% at maximum input flow. Pressure drop ranges from 30 psi (2 bar) at minimum rated input flow to 350 psi (24 bar) at maximum rated input flow. The valve hex size is 7/8 inch (22.2 mm), with an installation torque specification of 30 to 35 lbf ft (41 to 47 Nm). Weighing just .60 lb (.30 kg), this model incorporates Sun's floating style construction, minimizing internal part binding due to excessive torque or machining variations. In applications, the FSCHXAN ensures that the circuit leg with the greatest load receives a higher percentage of flow in dividing mode, while in combining mode, it directs more flow to the leg with the lowest load. However, users should be aware that without synchronization features or proper mechanical design, inaccuracies can lead to system lockup or cavitation in rigid mechanisms or motor circuits. Divisional and combining accuracy are equal across operations; however, below the minimum flow rating, the valve functions as a tee without control until sufficient flow is reached. The FSCHXAN also supports interchangeable cartridges for similar frame sizes and requires differential slip management through body-manifold orifices for optimal performance in tractive drive systems.

The Sun Hydraulics FSCHXAN (FSCHXAN) is a high-capacity, closed-center flow divider-combiner designed for tractive drive systems. This sliding-spool, pressure-compensated device efficiently splits flow in one direction and combines it in the opposite direction, offering approximately 15% greater capacity than standard models. It features a T31A cavity and Series 1 configuration, with a capacity range of 2 to 9 gpm (8 to 34 L/min) and a maximum operating pressure of 5000 psi (350 bar). The valve's divisional accuracy at minimum input flow is 50 \u00b16.5%, improving to \u00b13.5% at maximum input flow. Pressure drop ranges from 30 psi (2 bar) at minimum rated input flow to 350 psi (24 bar) at maximum rated input flow. The valve hex size is 7/8 inch (22.2 mm), with an installation torque specification of 30 to 35 lbf ft (41 to 47 Nm). Weighing just .60 lb (.30 kg), this model incorporates Sun's floating style construction, minimizing internal part binding due to excessive torque or machining variations. In applications, the FSCHXAN ensures that the circuit leg with the greatest load receives a higher percentage of flow in dividing mode, while in combining mode, it directs more flow to the leg with the lowest load. However, users should be aware that without synchronization features or proper mechanical design, inaccuracies can lead to system lockup or cavitation in rigid mechanisms or motor circuits. Divisional and combining accuracy are equal across operations; however, below the minimum flow rating, the valve functions as a tee without control until sufficient flow is reached. The FSCHXAN also supports interchangeable cartridges for similar frame sizes and requires differential slip management through body-manifold orifices for optimal performance in tractive drive systems.

High-capacity, closed-center flow divider/combiners are sliding-spool, pressure-compensated devices used to split flow in one direction and combine flow in the opposite direction. These valves have approximate 15% greater capacity than standard closed-center divider/combiners and are designed for use in tractive drive systems. Note: Accuracy on these cartridges is not equivalent to the accuracy of standard closed-center divider/combiners.

- All flow divider and divider/combiner cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

- Operating characteristics cause the leg of the circuit with the greatest load to receive the higher percentage of flow in dividing mode. If a rigid mechanism is used to tie actuators together, the lead actuator may pull the lagging actuator and cause it to cavitate.

- In combining mode, compensating characteristics will cause the leg of the circuit with the lowest load to receive the higher percentage of flow. If a synchronization feature is not included, an additive accuracy error will be experienced with each full stroke of the actuator.

- In applications involving rigid mechanisms between multiple actuators, operating inaccuracy will cause the eventual lock-up of the system. If the mechanical structure is not designed to allow for the operating inaccuracy inherent in the valve, damage may occur.

- In motor circuits, rigid frames or mechanisms that tie motors together, and/or complete mechanical synchronized motion of the output shaft of the motors, either by wheels to the pavement or sprockets to conveyors, will contribute to cavitation, lock-up and/or pressure intensification.

- Variations in speed and lock-up can be attributed to differences in motor displacement, motor leakage, wheel diameter variance and friction of wheels on the driving surface.

- Extreme pressure intensification can occur on multiple wheel drive vehicles.

- Differential slip for tractive drive systems must be achieved with orifices in the body/manifold.

- Divisional and combining accuracy are equal.

- Below the minimum flow rating there is not enough flow for the valve to modulate. It is effectively a tee. If flow starts at zero and rises, there will be no dividing or combining control until the flow reaches the minimum rating.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

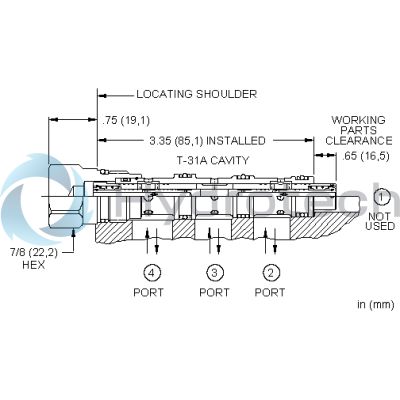

| Cavity | T-31A |

| Series | 1 |

| Capacity | 2 - 9 gpm8 - 34 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Divisional Accuracy at Minimum Input Flow | 50% ±6.5%50% ±6.5% |

| Divisional Accuracy at Max Input Flow | 50% ±3.5%50% ±3.5% |

| Pressure Drop at Minimum Rated Input Flow | 30 psi2 bar |

| Pressure Drop at Maximum Rated Input Flow | 350 psi24 bar |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Model Weight | .60 lb0,30 kg |

| Seal kit - Cartridge | Viton: 990-031-006 |

Show FAQ