SUN HYDRAULICS

FPHKECN912N

$416.80 USD

Tags:

- SUN HYDRAULICS

- Material:FPHKECN912N

- Model:FPHK-ECN@912N

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

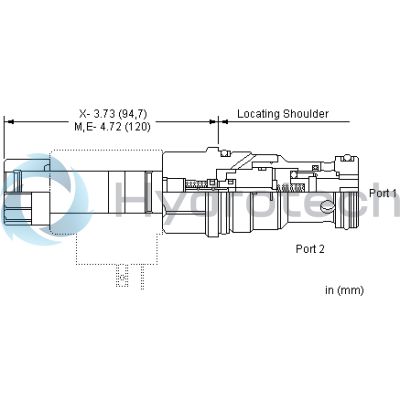

The Sun Hydraulics FPHKECN912N (FPHKECN912N) is a pilot-operated, normally closed, electroproportional throttle valve with reverse free flow check capabilities. This advanced hydraulic component is designed to modulate flow from port 1 to port 2 when the coil is energized, creating an opening force on the pilot stage that vents the main stage poppet. It allows for reverse free flow from port 2 to port 1, making it versatile for various hydraulic applications. The valve operates efficiently under pressures up to 5000 psi and supports a maximum capacity of 60 gpm (240 L/min). For enhanced performance, it is recommended to use an amplifier with current sensing and adjustable dither between 100 and 250 Hz. The valve features several manual override options, including a momentary-twist override that shifts the valve by twisting the manual override clockwise by 90 degrees. This model incorporates Sun's floating style construction, which minimizes internal parts binding due to excessive installation torque or cavity/cartridge machining variations. The FPHKECN912N can be installed in cavity T16A and requires an installation torque between 150-160 lbf ft (203-217 Nm). The solenoid tube diameter is .75 inches (19 mm), while the valve hex size measures at 1\u00bc inches (31.8 mm). For maintenance or replacements, Viton seal kits are available for both the cartridge and coil components. With its robust construction and adaptable features, this valve is suitable for precise flow control in demanding hydraulic systems.

The Sun Hydraulics FPHKECN912N (FPHKECN912N) is a pilot-operated, normally closed, electroproportional throttle valve with reverse free flow check capabilities. This advanced hydraulic component is designed to modulate flow from port 1 to port 2 when the coil is energized, creating an opening force on the pilot stage that vents the main stage poppet. It allows for reverse free flow from port 2 to port 1, making it versatile for various hydraulic applications. The valve operates efficiently under pressures up to 5000 psi and supports a maximum capacity of 60 gpm (240 L/min). For enhanced performance, it is recommended to use an amplifier with current sensing and adjustable dither between 100 and 250 Hz. The valve features several manual override options, including a momentary-twist override that shifts the valve by twisting the manual override clockwise by 90 degrees. This model incorporates Sun's floating style construction, which minimizes internal parts binding due to excessive installation torque or cavity/cartridge machining variations. The FPHKECN912N can be installed in cavity T16A and requires an installation torque between 150-160 lbf ft (203-217 Nm). The solenoid tube diameter is .75 inches (19 mm), while the valve hex size measures at 1\u00bc inches (31.8 mm). For maintenance or replacements, Viton seal kits are available for both the cartridge and coil components. With its robust construction and adaptable features, this valve is suitable for precise flow control in demanding hydraulic systems.

This valve is a pilot operated, normally closed, electro-proportional throttle with reverse free flow check. Energizing the coil generates an opening force on the pilot stage which vents the main stage poppet to open proportionally. Metered flow is from port 1 to port 2 with reverse free flow from port 2 to port 1.

- Capable of operating with pressures up to 5000 psi.

- Coils are interchangeable with Sun's other full flow, solenoid-operated valves and can be mounted on the tube in either direction.

- This cartridge has several manual override choices, including no manual override. See Option Configuration.

- For optimum performance, an amplifier with current sensing and adjustable dither should be used. Dither should be adjustable between 100 - 250 Hz.

- The momentary/twist override option "E" allows the operator to shift the valve by twisting the manual override clockwise 90 degrees.

- Depending on circuit requirements, a reverse free flow check bypassing the compensator may be needed when using the FPHK with an external compensator.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-16A |

| Series | 3 |

| Capacity | 60 gpm240 L/min. |

| Recommended dither frequency | 100 Hz100 Hz |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 10 drops/min.@5000 psi0,7 cc/min.@350 bar |

| Manual Override Force Requirement | 5 lbs/1000 psi @ Port 133 N/100 bar @ Port 1 |

| Deadband, nominal (as a percentage of input) | 25%25% |

| Manual Override Stroke | .06 in.1,50 mm |

| Solenoid Tube Diameter | .75 in.19 mm |

| Valve Hex Size | 1 1/4 in.31,8 mm |

| Valve Installation Torque | 150 - 160 lbf ft203 - 217 Nm |

| Model Weight | 1.50 lb0,70 kg |

| Model Weight (with coil) | 2.00 lb2.00 lb |

| Seal kit - Cartridge | Viton: 990-016-006 |

| Seal and nut kit - Coil | Viton: 990-770-006Viton: 990-770-006 |

Show FAQ