SUN HYDRAULICS

FMDATDV912N

$265.50 USD

Tags:

- SUN HYDRAULICS

- Material:FMDATDV912N

- Model:FMDA-TDV@912N

- Summary:Cartridge

Quantity in stock: 0

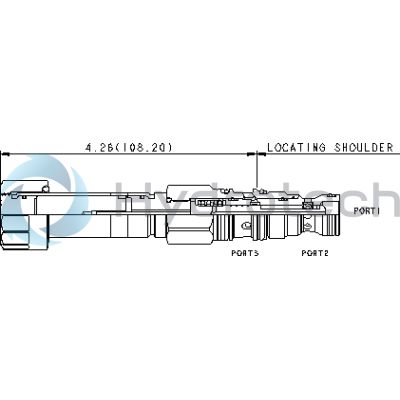

The Sun Hydraulics FMDATDV912N (FMDATDV912N) is a 3-way, meter-in, electro-proportional throttle valve designed for precise flow control in hydraulic circuits. When unenergized, the valve blocks supply at port 1 and drains port 2 to tank at port 3. Upon energizing the coil, a closing force on the spool creates a metering orifice from port 1 to port 2, proportional to the coil command current. This valve self-compensates in the 1 to 2 direction and can be used with an external compensator for pressure-compensated flow control. The flow from port 2 to port 3 is non-proportional and limited to approximately 1.5 gpm (6 L/min) for enhanced resolution and capacity. It's ideal for circuits with separate tank passages, such as cushion lock circuits, where two FMDA valves can create a meter-in/meter-out configuration. The FMDATDV912N can handle pressures up to 5000 psi (350 bar) across all ports and features interchangeable coils compatible with other Sun solenoid-operated valves. For optimal performance, it is recommended to use an amplifier with current sensing and adjustable dither between 100-250 Hz. The manual override options include a temporary detent mechanism with a life expectancy of about 7,000 cycles. The valve incorporates Sun's floating style construction, minimizing potential binding issues due to installation torque or machining variations. This valve fits into T-11A cavities and has a capacity of up to 9 gpm (34 L/min). It requires an installation torque of 30-35 lbf ft (41-47 Nm) and weighs approximately 1.10 lb (0.50 kg) with the coil included. Seal kits are available in Viton material for both cartridge and coil applications.

This valve is a 3-way, meter-in, electro-proportional throttle. The flow path, unenergized, has the supply blocked at port 1 and port 2 is drained to tank at port 3. Energizing the coil generates a closing force on the spool, creating a metering orifice in the 1 to 2 direction that is proportional to the coil command current. The valve self-compensates in the 1 to 2 direction and with the addition of an external compensator will provide pressure compensated flow control.

Flow in the 2 to 3 direction is not proportional and is limited in the interest of increased resolution and capacity. Flow capacity in the 2 to 3 direction is about 1.5 gpm (6 L/min). This valve is meant to be used in a circuit that has a separate passage to tank such as a cushion lock circuit. Two FMDA's in conjunction with a cushion lock circuit create a meter-in/meter-out 3 position 4-way.

- Note: Flow in the 2 to 3 direction is limited to about 1.5 gpm (5 L/pm).

- The transition between positions is closed.

- Using 2 3-ways to create a 4-way allows one to choose existing flow ranges instead of cutting a special spool.

- These valves may be pressure compensated by an external, modulating, logic element. Use LR_C-XHN for a bypass circuit or LP_C-XHN for a restrictive circuit.

- The valve provides a degree of self-compensation and may be used as a flow control. To increase the accuracy of flow control, an external, modulating, logic element can be used to maintain a constant flow over a wider range of flows and pressures. See performance curves for additional information.

- All ports will accept 5000 psi (350 bar).

- On models equipped with the D or L control, the detent mechanism in the manual override is meant for temporary actuation. The D, E, L and T manual control assemblies have a mechanical life expectancy of approximately 7,000 cycles.

- The momentary/twist override option "E" allows the operator to shift the valve by twisting the manual override clockwise 90 degrees.

- Coils are interchangeable with Sun's other full flow, solenoid-operated valves and can be mounted on the tube in either direction.

- For optimum performance, an amplifier with current sensing and adjustable dither should be used. Dither should be adjustable between 100 - 250 Hz.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-11A |

| Series | 1 |

| Capacity | 9 gpm34 L/min. |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 2 in³/min.@1000 psi30 cc/min.@70 bar |

| Manual Override Force Requirement | 5 lbs/1000 psi @ Port 133 N/100 bar @ Port 1 |

| Manual Override Stroke | .10 in.2,5 mm |

| Solenoid Tube Diameter | .75 in.19 mm |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Model Weight (with coil) | 1.10 lb0,50 kg |

| Seal kit - Cartridge | Viton: 990-411-006 |

| Seal and nut kit - Coil | Viton: 990-770-006Viton: 990-770-006 |

Show FAQ