SUN HYDRAULICS

FLHAXBN

$231.00 USD

Tags:

- SUN HYDRAULICS

- Material:FLHAXBN

- Model:FLHA-XBN

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics FLHAXBN (Material Number: FLHAXBN) is a robust filter element designed for hydraulic systems, ensuring optimal performance by capturing errant particles that may bypass the main system filter or result from component failure. This Surface Type Last Chance element features a 304 stainless steel mesh media, supported by a perforated sheet tube, offering a 40 micron nominal rating and a 63 micron absolute rating. It is engineered for installation directly above the subplate to protect the entire valve stack from contaminants. The differential crush pressure of this filter is rated at 3000 psid (210 bar), with a flow path strictly from Port 2 to Port 1. It is crucial not to reverse this flow path, even if a reverse free flow check valve is installed. The FLHAXBN is suitable for systems with phosphate ester fluids when equipped with EPDM seals; however, these seals should not be exposed to petroleum-based fluids, greases, or lubricants as they may cause damage. With a capacity of 40 gpm (160 L/min) and maximum operating pressure of 5000 psi (350 bar), the filter element fits into T16A cavities and requires installation torque between 150 - 160 lbf-ft (203 - 217 Nm). During regular operation within correctly assembled systems, this element remains unobtrusive while providing critical protection against sudden component failures, ensuring longevity and reliability of hydraulic operations.

The Sun Hydraulics FLHAXBN (Material Number: FLHAXBN) is a robust filter element designed for hydraulic systems, ensuring optimal performance by capturing errant particles that may bypass the main system filter or result from component failure. This Surface Type Last Chance element features a 304 stainless steel mesh media, supported by a perforated sheet tube, offering a 40 micron nominal rating and a 63 micron absolute rating. It is engineered for installation directly above the subplate to protect the entire valve stack from contaminants. The differential crush pressure of this filter is rated at 3000 psid (210 bar), with a flow path strictly from Port 2 to Port 1. It is crucial not to reverse this flow path, even if a reverse free flow check valve is installed. The FLHAXBN is suitable for systems with phosphate ester fluids when equipped with EPDM seals; however, these seals should not be exposed to petroleum-based fluids, greases, or lubricants as they may cause damage. With a capacity of 40 gpm (160 L/min) and maximum operating pressure of 5000 psi (350 bar), the filter element fits into T16A cavities and requires installation torque between 150 - 160 lbf-ft (203 - 217 Nm). During regular operation within correctly assembled systems, this element remains unobtrusive while providing critical protection against sudden component failures, ensuring longevity and reliability of hydraulic operations.

Sun filter elements are available as Surface Type (Last Chance) and Depth Style elements. The flow path is Port 2 to Port 1 and should not be used in reverse, even with a reverse free flow check valve installed. The elements have a high collapse pressure and are intended to be used in line with the system. Filter life will depend on initial system cleanliness and the amount of dirt ingression to the system when operating.

- Installation directly above the subplate will protect the entire valve stack from particles.

- Differential crush pressure is 3000 psid (210 bar).

- The flow path is Port 2 to Port 1 only.

- Cartridges with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- Surface type element features a 304 stainless steel mesh media. All internal components are 304 stainless steel.

- Surface Type elements have a 40 micron nominal rating (63 micron absolute).

- Surface Type elements are designed to capture errant particles that may not be trapped in the main system filter or particles resulting from a component failure.

- With a correctly assembled system, Surface Type elements will be unnoticed during regular operation, but will provide protection from sudden component failure.

- Surface Type (Last Chance) elements have a single layer stainless steel mesh supported by perforated sheet tube.

- Depth type elements are available in 3 µm, 10 µm, and 25 µm nominal ranges.

- 3, 10, and 25 micron elements have a Beta ratio as shown in the Performance Curves tab.

- Depth Type elements feature a pleated microglass media with clear zinc coated components.

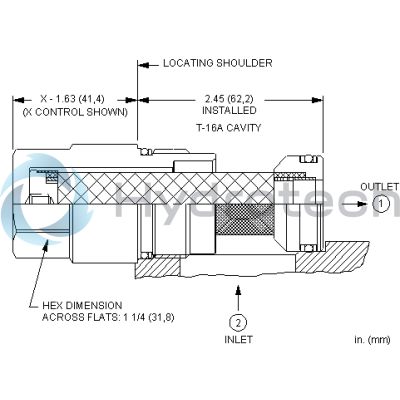

| Cavity | T-16A |

| Series | 3 |

| Capacity | 40 gpm160 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Valve Hex Size | 1 1/4 in.31,8 mm |

| Valve Installation Torque | 150 - 160 lbf ft203 - 217 Nm |

| Seal kit - Cartridge | Viton: 990-016-006 |

Show FAQ