SUN HYDRAULICS

DSGHXEV

$342.00 USD

Tags:

- SUN HYDRAULICS

- Material:DSGHXEV

- Model:DSGH-XEV

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

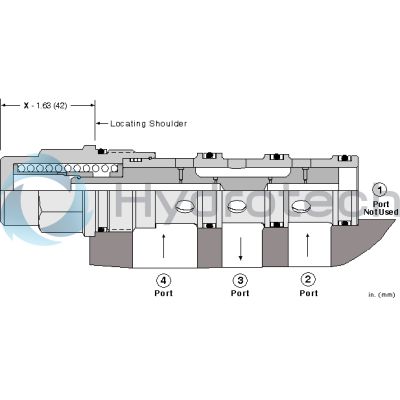

The Sun Hydraulics DSGHXEV (DSGHXEV) is a lowside hot oil shuttle cartridge designed to efficiently divert hot oil from the low-pressure side of a closed-loop hydraulic system. This valve features a spring-centered mechanism that blocks all ports when both work ports, 2 and 4, are at equal pressures. When there is a pressure differential, the valve connects the lower pressure work port to the common port, 3, allowing for efficient thermal management within hydraulic circuits. The cartridge includes a hydraulic stop to prevent mechanical impact and potential internal damage, promoting longevity and reliability. Additionally, this feature facilitates confirmation of hot oil relief settings while in neutral transmission mode. Users should be cautious when selecting shift pressures due to potential low shift values inadvertently shifting the valve with charge pump pressure alone. The valve fits into a T-33A cavity but does not utilize the nose port (port 1). It employs Sun's floating style construction, minimizing binding risks from excessive installation torque or machining variations. The DSGHXEV supports a flow capacity of up to 40 gpm (160 L/min) and can operate under maximum pressures of 5000 psi (350 bar). It has a pilot flow rate of 4-6 in\u00b3/min (0.75 L/min) and requires an installation torque between 150 and 160 lbf ft (203 - 217 Nm). Weighing approximately 1.40 lb (0.65 kg), this robust component is suitable for applications requiring reliable thermal management in hydraulic systems.

The Sun Hydraulics DSGHXEV (DSGHXEV) is a lowside hot oil shuttle cartridge designed to efficiently divert hot oil from the low-pressure side of a closed-loop hydraulic system. This valve features a spring-centered mechanism that blocks all ports when both work ports, 2 and 4, are at equal pressures. When there is a pressure differential, the valve connects the lower pressure work port to the common port, 3, allowing for efficient thermal management within hydraulic circuits. The cartridge includes a hydraulic stop to prevent mechanical impact and potential internal damage, promoting longevity and reliability. Additionally, this feature facilitates confirmation of hot oil relief settings while in neutral transmission mode. Users should be cautious when selecting shift pressures due to potential low shift values inadvertently shifting the valve with charge pump pressure alone. The valve fits into a T-33A cavity but does not utilize the nose port (port 1). It employs Sun's floating style construction, minimizing binding risks from excessive installation torque or machining variations. The DSGHXEV supports a flow capacity of up to 40 gpm (160 L/min) and can operate under maximum pressures of 5000 psi (350 bar). It has a pilot flow rate of 4-6 in\u00b3/min (0.75 L/min) and requires an installation torque between 150 and 160 lbf ft (203 - 217 Nm). Weighing approximately 1.40 lb (0.65 kg), this robust component is suitable for applications requiring reliable thermal management in hydraulic systems.

Low-side (hot oil) shuttle cartridges allow hot oil to be diverted from the low pressure side of a closed loop system. When both work ports (ports 2 and 4) are at equal pressures the valve is spring-centered to an all-ports-blocked position. When one of the work ports (port 2 or 4) sees a higher pressure the opposite work port is connected to the common port (port 3).

- The spool incorporates a hydraulic stop that eliminates mechanical impact and therefore the potential for internal damage.

- The hydraulic stop results in a small pilot flow from the high side work port (port 2 or 4) to the common port (port 3).

- A unique feature due to the hydraulic stop is that the hot oil relief setting can be confirmed with the transmission in neutral.

- NOTE: Low shift values can potentially result in charge pump pressure alone inadvertently shifting the valve. Use care when selecting shift pressure.

- Although this valve goes into a 4-port cavity, the nose (port 1) is not used.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-33A |

| Series | 3 |

| Capacity | 40 gpm160 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Pilot Flow | 46 in³/min.0,75 L/min. |

| Valve Hex Size | 1 1/4 in.31,8 mm |

| Valve Installation Torque | 150 - 160 lbf ft203 - 217 Nm |

| Model Weight | 1.40 lb0,65 kg |

| Seal kit - Cartridge | Viton: 990-033-006 |

Show FAQ