SUN HYDRAULICS

DNDCXTE2E12V

$1,185.00 USD

Tags:

- SUN HYDRAULICS

- Material:DNDCXTE2E12V

- Model:DNDC-XTE@2E12V

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics DNDCXTE2E12V (Material Number: DNDCXTE2E12V) is a direct acting, solenoid-operated, 4-way, 3-position spool valve designed to provide reliable hydraulic control. This valve is spring-centered to the neutral position and allows for different flow configurations based on coil activation. When coil A is energized, fluid flows from port 3 P to port 2 A and from port 4 B to port 1 T. Conversely, energizing coil B directs flow from port 3 to port 4 and from port 2 to port 1. The solenoid tube assembly is robustly rated for fatigue at pressures up to 5000 psi (350 bar), making it suitable for demanding applications. This valve does not require a minimum hydraulic pressure for operation and features a wet armature design that immerses the armature in working fluid, which can be affected by prolonged coil energization due to heat exposure. In systems utilizing differential flow circuits, it is recommended that higher return flows are directed through port 2 A to port 1 T. The valve can be fitted with EPDM seals suitable for phosphate ester fluids but should avoid petroleum-based products as they may damage the seals. The DNDCXTE2E12V offers versatility with various coil termination and voltage options, including surge protection features. Its unique magnetic design ensures high efficiency by delivering significant spool actuating force per watt of energy used. With a capacity of up to 5 gpm (20 L/min) and a response time of approximately 50 ms, this valve suits high-frequency operations up to 15,000 cycles per hour. Installation requires a torque between 30-35 lbf ft (41-47 Nm). Additionally, this model incorporates Sun's floating style construction which minimizes internal binding risks due to installation or machining variations.

The Sun Hydraulics DNDCXTE2E12V (Material Number: DNDCXTE2E12V) is a direct acting, solenoid-operated, 4-way, 3-position spool valve designed to provide reliable hydraulic control. This valve is spring-centered to the neutral position and allows for different flow configurations based on coil activation. When coil A is energized, fluid flows from port 3 P to port 2 A and from port 4 B to port 1 T. Conversely, energizing coil B directs flow from port 3 to port 4 and from port 2 to port 1. The solenoid tube assembly is robustly rated for fatigue at pressures up to 5000 psi (350 bar), making it suitable for demanding applications. This valve does not require a minimum hydraulic pressure for operation and features a wet armature design that immerses the armature in working fluid, which can be affected by prolonged coil energization due to heat exposure. In systems utilizing differential flow circuits, it is recommended that higher return flows are directed through port 2 A to port 1 T. The valve can be fitted with EPDM seals suitable for phosphate ester fluids but should avoid petroleum-based products as they may damage the seals. The DNDCXTE2E12V offers versatility with various coil termination and voltage options, including surge protection features. Its unique magnetic design ensures high efficiency by delivering significant spool actuating force per watt of energy used. With a capacity of up to 5 gpm (20 L/min) and a response time of approximately 50 ms, this valve suits high-frequency operations up to 15,000 cycles per hour. Installation requires a torque between 30-35 lbf ft (41-47 Nm). Additionally, this model incorporates Sun's floating style construction which minimizes internal binding risks due to installation or machining variations.

This direct acting, solenoid-operated, 4-way, 3-position spool valve is spring centered to the neutral position. When coil A is energized, the flow is from port 3 (P) to port 2 (A) and from port 4 (B) to port 1 (T). When coil B is energized, the flow is from port 3 to port 4 and from port 2 to port 1.

- The solenoid tube assembly is fatigue rated for 5000 psi (350 bar) service.

- This valve is direct actuated and requires no minimum hydraulic pressure for operation.

- In differential flow circuits, the higher return flow should be directed through port 2 (A) to port 1 (T).

- Cartridges with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- This valve utilizes a wet armature design. This means that the working fluid surrounds the armature and is exposed to the heat generated by the coil. This can be a factor if the coil is energized for long periods of time. Some fluids, notably water/glycol mixtures, break down at these temperatures over time and form varnishes that will affect the function of the cartridge.

- A wide variety of coil termination and voltage options are available, with and without surge protection. See the CONFIGURATION section.

- The solenoid's unique magnetic design results in a high efficiency solenoid, yielding high spool actuating force per Watt expended, leading to reliable valve shifting.

- Coils are interchangeable with other Sun Series 1 solenoid products and can be mounted on the tube in either direction.

- Coil connector options offer ratings up to IP69K. See individual coil product pages for details. Additional weatherized coils and kits are available for more complete environmental protection.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

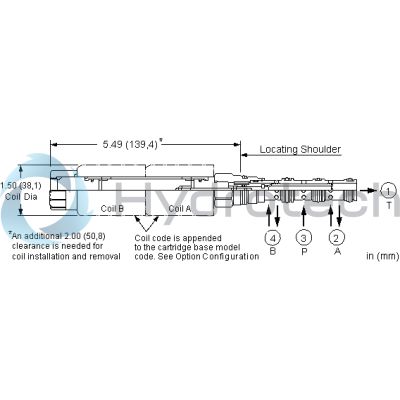

| Cavity | T-31A |

| Series | 1 |

| Capacity | 5 gpm20 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Response Time - Typical | 50 ms50 ms |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 10 in³/min.@3000 psi160 cc/min.@210 bar |

| Switching Frequency | 15000 cycles/hr15000 cycles/hr |

| Solenoid Tube Diameter | .75 in.19 mm |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Seal kit - Cartridge | Viton: 990-431-006 |

| Seal and nut kit - Coil | Viton: 990-770-006Viton: 990-770-006 |

Show FAQ