SUN HYDRAULICS

CXGDXCN/AP

$192.40 USD

Tags:

- SUN HYDRAULICS

- Material:CXGDXCN/AP

- Model:CXGD-XCN/AP

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

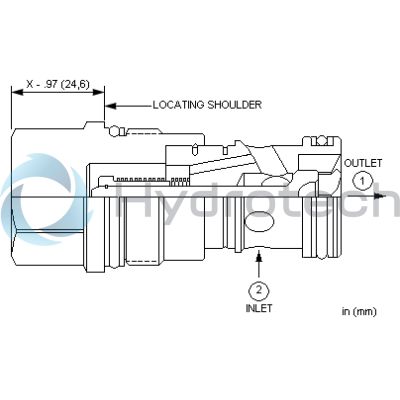

The Sun Hydraulics CXGDXCN/AP (CXGDXCN/AP) is a high-performance check valve designed for hydraulic systems requiring reliable, one-way flow control. This model operates as a free-flow, side-to-nose check valve, allowing fluid to move freely from inlet port 2 to outlet port 1 while preventing flow in the opposite direction. It is particularly useful in applications where manifold drillings may have been executed incorrectly, acting as a circuit saver by accommodating these variations without the need for new components or extensive modifications. The CXGDXCN/AP is engineered to handle a maximum operating pressure of 5000 psi (350 bar) at both ports and supports flow capacities up to 60 gpm (240 L/min). It features extremely low leakage rates, with a maximum of less than one drop per minute (0.07 cc/min), ensuring efficient and clean operation in critical systems. The valve\u2019s robust construction includes Sun\u2019s floating style design which minimizes internal parts binding that could result from excessive installation torque or machining variations of the cavity/cartridge. This model uses EPDM seals configured specifically for systems utilizing phosphate ester fluids, while exposure to petroleum-based fluids can damage the seals. It fits into a T16A cavity and requires an installation torque between 150-160 lbf ft (203-217 Nm). The overall weight of the valve is minimal at approximately 1.60 lbs (0.70 kg), contributing to its ease of integration into existing hydraulic circuits without adding significant weight or complexity.

The Sun Hydraulics CXGDXCN/AP (CXGDXCN/AP) is a high-performance check valve designed for hydraulic systems requiring reliable, one-way flow control. This model operates as a free-flow, side-to-nose check valve, allowing fluid to move freely from inlet port 2 to outlet port 1 while preventing flow in the opposite direction. It is particularly useful in applications where manifold drillings may have been executed incorrectly, acting as a circuit saver by accommodating these variations without the need for new components or extensive modifications. The CXGDXCN/AP is engineered to handle a maximum operating pressure of 5000 psi (350 bar) at both ports and supports flow capacities up to 60 gpm (240 L/min). It features extremely low leakage rates, with a maximum of less than one drop per minute (0.07 cc/min), ensuring efficient and clean operation in critical systems. The valve\u2019s robust construction includes Sun\u2019s floating style design which minimizes internal parts binding that could result from excessive installation torque or machining variations of the cavity/cartridge. This model uses EPDM seals configured specifically for systems utilizing phosphate ester fluids, while exposure to petroleum-based fluids can damage the seals. It fits into a T16A cavity and requires an installation torque between 150-160 lbf ft (203-217 Nm). The overall weight of the valve is minimal at approximately 1.60 lbs (0.70 kg), contributing to its ease of integration into existing hydraulic circuits without adding significant weight or complexity.

Free-flow, side-to-nose check valves are on/off circuit components that allow free flow from the inlet (port 2) to the outlet (port 1) and block flow in the opposite direction.

- Two-port check valves share the same cavity for a given frame size, however, pay close attention as flow paths may be in opposite directions.

- These check valves are considered circuit savers for existing circuits where manifold drillings are incorrect. The capacity of side-to-nose (port 2 to port 1) 2-port check valves is approximately 30% less than preferred models with a nose-to-side (port 1 to port 2) flow path.

- Check valves offer extremely low leakage rates with a maximum leakage of less than 1 drop per minute (0,07 cc/min).

- Will accept 5000 psi (350 bar) at ports 1 and 2.

- Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage the seals.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-16A |

| Series | 3 |

| Capacity | 60 gpm240 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 1 drops/min.0,07 cc/min. |

| Valve Hex Size | 1 1/4 in.31,8 mm |

| Valve Installation Torque | 150 - 160 lbf ft203 - 217 Nm |

| Model Weight | 1.60 lb0,70 kg |

| Seal kit - Cartridge | Viton: 990-016-006 |

Show FAQ