SUN HYDRAULICS

CDAQMCV

$62.80 USD

Tags:

- SUN HYDRAULICS

- Material:CDAQMCV

- Model:CDAQ-MCV

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

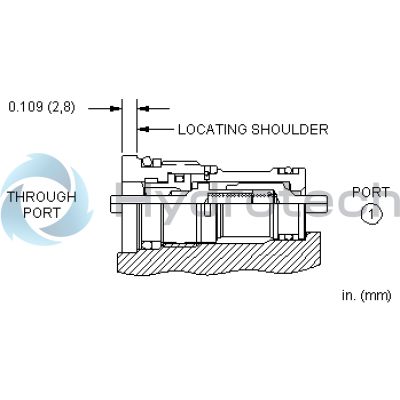

The Sun Hydraulics CDAQMCV (CDAQMCV) is a specialized phaser check valve designed for precision operation in hydraulic systems. This valve features a unique back-to-back poppet arrangement, mechanically actuated to ensure reliable flow control through the piston of a cylinder. Specifically engineered for installation into the piston or rod of a cylinder, the CDAQMCV activates when the cylinder reaches the end of its stroke, pushing the poppet off its seat to allow flow and enabling synchronization of dual cylinder systems in applications like steering. The design of this valve ensures minimal leakage, with rates less than one drop per minute (0.07 cc/min), and it incorporates Sun's floating style construction to prevent internal parts from binding due to excessive installation torque or machining variations. The CDAQMCV operates at a maximum pressure of 5000 psi (350 bar) and has a flow capacity of 1.25 gpm (4.7 L/min). It also features an internal hex size of 5/16 in. (8 mm) and requires an installation torque between 20 - 25 lbf·ft (27 - 33 Nm). Key operational notes include that this valve should not handle side forces or be used as a mechanical stop; it must have axial actuating direction with contact surfaces perpendicular to the valve axis within specified tolerances. The maximum stroke for the poppet is limited to .047 in (1.2 mm), ensuring controlled operation without reliance on the valve itself as a stop mechanism. This phaser check valve is particularly beneficial in applications where it is critical to manage end-of-stroke forces on cylinder components, such as rod glands, and prevent false pressure readings in monitoring setups. Additionally, its application in vertically mounted cylinders helps bleed air effectively at stroke ends, enhancing overall system efficiency and reliability.

The Sun Hydraulics CDAQMCV (CDAQMCV) is a specialized phaser check valve designed for precision operation in hydraulic systems. This valve features a unique back-to-back poppet arrangement, mechanically actuated to ensure reliable flow control through the piston of a cylinder. Specifically engineered for installation into the piston or rod of a cylinder, the CDAQMCV activates when the cylinder reaches the end of its stroke, pushing the poppet off its seat to allow flow and enabling synchronization of dual cylinder systems in applications like steering. The design of this valve ensures minimal leakage, with rates less than one drop per minute (0.07 cc/min), and it incorporates Sun's floating style construction to prevent internal parts from binding due to excessive installation torque or machining variations. The CDAQMCV operates at a maximum pressure of 5000 psi (350 bar) and has a flow capacity of 1.25 gpm (4.7 L/min). It also features an internal hex size of 5/16 in. (8 mm) and requires an installation torque between 20 - 25 lbf·ft (27 - 33 Nm). Key operational notes include that this valve should not handle side forces or be used as a mechanical stop; it must have axial actuating direction with contact surfaces perpendicular to the valve axis within specified tolerances. The maximum stroke for the poppet is limited to .047 in (1.2 mm), ensuring controlled operation without reliance on the valve itself as a stop mechanism. This phaser check valve is particularly beneficial in applications where it is critical to manage end-of-stroke forces on cylinder components, such as rod glands, and prevent false pressure readings in monitoring setups. Additionally, its application in vertically mounted cylinders helps bleed air effectively at stroke ends, enhancing overall system efficiency and reliability.

The phaser check is a pair of checks, back-to-back, with both poppets mechanically actuated. The valve is meant to be installed into the piston or rod of a cylinder. When the cylinder reaches the end of its stroke the poppet in the phaser check is shoved off its seat allowing flow through the piston. This allows two cylinders to get back into phase.

- This valve is not designed to handle side forces. Actuating direction must be axial, and contact surface must be perpendicular to valve axis to within 5°.

- This valve is NOT meant to be cam operated.

- This valve is NOT to be used in place of a mechanical stop.

- Maximum stroke of the poppet must be limited to .047 in. (1,2 mm) by a mechanical stop other than the valve itself.

- Note: Port 2 of the T-162A cavity is not used with this valve.

- A cylinder that does its work while extending can put a large load on the rod gland at the end of its stroke. A phaser check in the piston can limit the unnecessary force on the gland.

- If you need to monitor the pressure in a cylinder, a phaser check can prevent the trapping of a false pressure value by a load holding valve.

- A phaser check in the piston of a vertically mounted cylinder will bleed air at the end of the stroke.

- Phaser checks in the pistons of master/slave cylinders will synchronize the cylinders simply by taking the mechanism to the end of its travel in both directions. This lends itself to dual cylinder steering applications.

- Check valves offer extremely low leakage rates with a maximum leakage of less than 1 drop per minute (0,07 cc/min).

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

| Cavity | T-162DP |

| Series | 0 |

| Capacity | 1.25 gpm4,7 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 1 drops/min.0,07 cc/min. |

| Valve Internal Hex Size | 5/16 in.8 mm |

| Valve Installation Torque | 20 - 25 lbf ft27 - 33 Nm |

| Seal kit - Cartridge | Viton: 990-162-006 |

Show FAQ