SUN HYDRAULICS

CBBDLDV

$76.40 USD

Tags:

- SUN HYDRAULICS

- Material:CBBDLDV

- Model:CBBD-LDV

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics CBBDLDV (CBBDLDV) is a meticulously engineered counterbalance valve designed to manage the flow and control of hydraulic systems handling overrunning loads. This valve features a dual-function mechanism: a check valve that permits free flow from the directional valve port to the load port, and a direct-acting, pilot-assisted relief valve that regulates flow between ports. The pilot assist functionality at a specific port effectively reduces the relief valve's setting based on the predetermined pilot ratio, enhancing the operational efficiency of hydraulic systems. The CBBDLDV model is set to be adjusted with minimal effort—turning the adjustment clockwise decreases the setting and releases the load, with full clockwise providing settings below 350 psi (24 bar). The design incorporates Sun Hydraulics’ floating style construction which minimizes potential internal parts binding caused by excessive installation torque or variances in cavity/cartridge machining. This ensures longevity and reliability even under rigorous conditions. With an option between two check valve cracking pressures, users can select according to their specific application needs; typically, a 3 psi (0.2 bar) check is standard unless actuator cavitation is of concern. Additionally, this model boasts positive seals between all ports ensuring no internal leakage and optimal performance. Regarding configurations, users can install Sun counterbalance cartridges directly into cavities machined into an actuator housing for added protection and circuit stiffness. This model’s versatility is further highlighted by its interchangeability with all port counterbalance, load control, and pilot-to-open check cartridges within a given frame size. This valve is particularly suited for applications requiring precise motion control such as in mobile hydraulics and industrial machinery where stability under dynamic load conditions is crucial. With its robust design and configurable settings, the Sun Hydraulics CBBDLDV counterbalance valve represents a reliable solution for advanced hydraulic system management.

The Sun Hydraulics CBBDLDV (CBBDLDV) is a meticulously engineered counterbalance valve designed to manage the flow and control of hydraulic systems handling overrunning loads. This valve features a dual-function mechanism: a check valve that permits free flow from the directional valve port to the load port, and a direct-acting, pilot-assisted relief valve that regulates flow between ports. The pilot assist functionality at a specific port effectively reduces the relief valve's setting based on the predetermined pilot ratio, enhancing the operational efficiency of hydraulic systems. The CBBDLDV model is set to be adjusted with minimal effort—turning the adjustment clockwise decreases the setting and releases the load, with full clockwise providing settings below 350 psi (24 bar). The design incorporates Sun Hydraulics’ floating style construction which minimizes potential internal parts binding caused by excessive installation torque or variances in cavity/cartridge machining. This ensures longevity and reliability even under rigorous conditions. With an option between two check valve cracking pressures, users can select according to their specific application needs; typically, a 3 psi (0.2 bar) check is standard unless actuator cavitation is of concern. Additionally, this model boasts positive seals between all ports ensuring no internal leakage and optimal performance. Regarding configurations, users can install Sun counterbalance cartridges directly into cavities machined into an actuator housing for added protection and circuit stiffness. This model’s versatility is further highlighted by its interchangeability with all port counterbalance, load control, and pilot-to-open check cartridges within a given frame size. This valve is particularly suited for applications requiring precise motion control such as in mobile hydraulics and industrial machinery where stability under dynamic load conditions is crucial. With its robust design and configurable settings, the Sun Hydraulics CBBDLDV counterbalance valve represents a reliable solution for advanced hydraulic system management.

Counterbalance valves with pilot assist are meant to control an overrunning load. The check valve allows free flow from the directional valve (port 2) to the load (port 1) while a direct-acting, pilot-assisted relief valve controls flow from port 1 to port 2. Pilot assist at port 3 lowers the effective setting of the relief valve at a rate determined by the pilot ratio.

Other names for this valve include motion control valve and over center valve.

- Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

- Turn adjustment clockwise to decrease setting and release load.

- Full clockwise setting is less than 200 psi (14 bar).

- Backpressure at port 2 adds to the effective relief setting at a ratio of 1 plus the pilot ratio times the backpressure.

- Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages.

- Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit.

- Two check valve cracking pressures are available. Use the 25 psi (1,7 bar) check unless actuator cavitation is a concern.

- This valve has positive seals between all ports.

- All 3-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

- Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP for external stainless steel components, or /LH for external zinc-nickel plated components. See the CONFIGURATION section for all options. For further details, please see the Materials of Construction page located under TECH RESOURCES.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

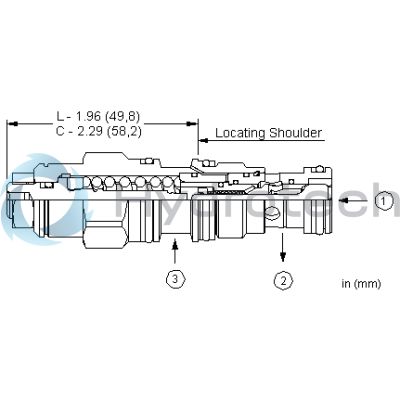

| Cavity | T-11A |

| Series | 1 |

| Capacity | 10 gpm40 L/min. |

| Pilot Ratio | 4.5:14.5:1 |

| Maximum Recommended Load Pressure at Maximum Setting | 3850 psi270 bar |

| Maximum Setting | 5000 psi350 bar |

| Factory Pressure Settings Established at | 2 in³/min.30 cc/min. |

| Maximum Valve Leakage at Reseat | 5 drops/min.0,3 cc/min. |

| Adjustment - Number of Counterclockwise Turns to Increase Setting | 3.753.75 |

| Operating Characteristic | Semi-restrictiveSemi-restrictive |

| Reseat | >85% of setting>85% of setting |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Adjustment Screw Internal Hex Size | 5/32 in.4 mm |

| Locknut Hex Size | 9/16 in.15 mm |

| Locknut Torque | 80 - 90 lbf in.9 - 10 Nm |

| Model Weight | .40 lb0,20 kg |

| Seal kit - Cartridge | Viton: 990-011-006 |

Show FAQ