BOSCH REXROTH

R900481623

$397.00 USD

- BOSCH REXROTH

- Material:R900481623

- Model:Z2FS6-2-4X/1QV

Quantity in stock: 14

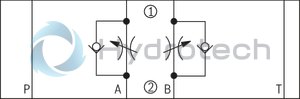

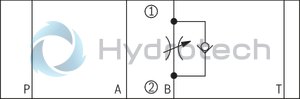

The Bosch Rexroth Z2FS6-2-4X/1QV (R900481623) is a high-performance industrial hydraulic twin throttle check valve designed for precise flow regulation and control. This mechanically actuated valve is engineered to reliably throttle the flow to a set value, featuring direct actuation for responsive performance. The Z2FS6-2-4X/1QV comes with a setscrew that includes a lock nut for fine adjustment, allowing users to achieve precise control over hydraulic flow rates. The model boasts a spool symbol configuration of A A, B B or A A, B B, providing flexibility in application. It is capable of handling maximum pressure with utmost reliability and is classified under Productgroup ID. The valve accommodates multiple ports and its mechanical actuation type ensures robust operation in various industrial settings. With its sandwich plate design, the Z2FS6-2-4X/1QV offers ease of installation and maintenance. It conforms to NFPA T.. R D SizeCETOP D and ISO connection diagram standards, ensuring compatibility with a wide range of systems. The number of switching positions adds to its versatility while the weight reflects its solid construction. Seals made from FKM material ensure that the valve operates effectively with a variety of hydraulic fluids including HL, HLP, HLPD, HVLP, HVLPD, HETG, HEES, HEPG, HFDU, and HFDR types. Whether it's for main or pilot flow limitation in supply or discharge throttling applications, this Bosch Rexroth valve provides reliable performance with options for setscrew or lockable rotary knob adjustments. The Z2FS6-2-4X/1QV is designed for both main flow limitation in version Q and pilot flow limitation applications. Its sandwich plate design allows for straightforward installation between directional valves and subplates or between pilot control valves and main valves depending on the requirement. With its robust design and precise control features, this Bosch Rexroth hydraulic valve is an essential component for efficient fluid power management in industrial equipment.

Size 6, A1 → A2, B1 → B2 or A2 → A1, B2 → B1, mechanically actuated

Industrial hydraulic valve in a high performance range. Reliable throttling of the flow to setting value.

Unpacked Weight: 1.065 kg

The valve type Z2FS is a twin throttle check valve in sandwich plate design. It is used for the main or pilot flow limitation of one or two actuator ports.

Two throttle check valves aligned symmetrically to each other limit flows in one direction and allow free return flow in the opposite direction.

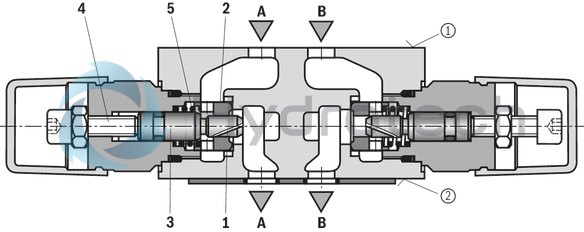

In case of supply throttling, the hydraulic fluid is directed through channel A➀ via throttling point (1) formed by the valve seat (2) and the throttle spool (3) to actuator A➁. The throttle spool (3) can be axially adjusted via the setscrew (4) for adjustment of the throttling point (1).

The hydraulic fluid return flow from actuator A➁ displaces the valve seat (2) against the spring (5) in the direction of the throttle spool (3) and enables the unobstructed flow as check valve. Depending on the installation position, the throttling effect may occur in supply or discharge.

Main flow limitation (Version "2Q")

For actuator velocity adjustment (main flow limitation), the twin throttle check valve is installed between the directional valve and the subplate.

Pilot flow limitation (Version "1Q")

With pilot-operated directional valves, the twin throttle check valve can be applied for switching time adjustment (pilot flow limitation). In this case, it is installed between the pilot control valve and the main valve.

Type Z2FS 6 –2…

(Supply throttling)

|

➀ |

component side |

|

➁ |

plate side |

| Direct actuated |

| Setscrew with lock nut |

| Fine adjustment |

| Component series 4X |

| Maximum flow 80 l/min |

| Size 6 |

| Maximum operating pressure 315 bar |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Spool symbol | A1 → A2, B1 → B2 or A2 → A1, B2 → B1 |

| Max. pressure | 350 |

| Productgroup ID | 9,10,11,12,13,14 |

| Number of ports | 4 |

| Type of actuation | with mechanical actuation |

| Size | 6 |

| Max. flow | 80 |

| Type of connection | Sandwich plate |

| Connection diagram NFPA | NFPA T3.5.1 R2-2002 D03 |

| Size_CETOP | D03 |

| Connection diagram | ISO 4401-03-02-0-05 |

| Number of switching positions | 2 |

| Weight | 1.065 |

| Seals | FKM |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HETG,HEES,HEPG,HFDU,HFDR |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

||

|

Z2FS |

6 |

– |

4X |

/ |

* |

|

01 |

Twin throttle check valve, sandwich plate design |

Z2FS |

|

02 |

Size 6 |

6 |

|

03 |

Throttle check valve side A and B |

– 1) |

|

Throttle check valve side A |

A |

|

|

Throttle check valve side B |

B |

|

|

Adjustment type |

||

|

04 |

Setscrew with lock nut and protective cap |

2 |

|

Lockable rotary knob with scale |

3 2) |

|

|

Spindle with internal hexagon and scale |

5 |

|

|

Rotary knob with scale |

7 |

|

|

05 |

Component series 40 … 49 (40 … 49: unchanged installation and mounting dimensions) |

4X |

|

06 |

With fine adjustment |

1Q |

|

Standard version |

2Q |

|

|

Seal material |

||

|

07 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) |

||

|

08 |

no code |

|

|

With locating hole |

/60 3) |

|

|

09 |

Further details in the plain text |

* |

| 1) Identical adjustment types on sides A and B | |

| 2) H-key with material no. R900008158 is included in the scope of delivery. | |

| 3) Locking pin ISO 8752-3x8-St, material no. R900005694 (separate order) |

Preferred types and standard units are contained in the EPS (standard price list).

general

|

Size |

6 | ||

|

Weight (approx.) |

kg |

0.8 | |

|

Installation position |

any | ||

|

Ambient temperature range |

°C |

-20 … +80 | |

hydraulic

|

Size |

6 | ||

|

Maximum operating pressure |

bar |

315 | |

|

Maximum flow |

l/min |

80 | |

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range |

°C |

-20 … +80 | |

|

Viscosity range |

mm²/s |

10 … 800 | |

|

Maximum admissible degree of contamination of the hydraulic fluid 1) |

Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oils and related hydrocarbons |

HL, HLP, HLPD |

NBR, FKM |

DIN 51524 |

|

|

Environmentally compatible |

Insoluble in water |

HETG |

NBR, FKM |

ISO 15380 |

|

HEES |

FKM |

|||

|

Soluble in water |

HEPG |

FKM |

ISO 15380 |

|

|

Containing water |

Water-free |

HFDU, HFDR |

FKM |

ISO 12922 |

|

Containing water |

HFC (Fuchs Hydrotherm 46M, Petrofer Ultra Safe 620) |

NBR |

ISO 12922 |

|

|

Important information on hydraulic fluids! For further information and data on the use of other hydraulic fluids, please refer to data sheet 90220 or contact us! There may be limitations regarding the technical valve data (temperature, pressure range, life cycle, maintenance intervals, etc.)!Flame-resistant – containing water: Maximum operating pressure 210 bar Maximum hydraulic fluid temperature 60 °C Expected life cycle as compared to HLP hydraulic oil 30 % to 100 % |

||||

For applications outside these parameters, please consult us!

(measured with HLP46, ϑOil = 40 ±5 °C)

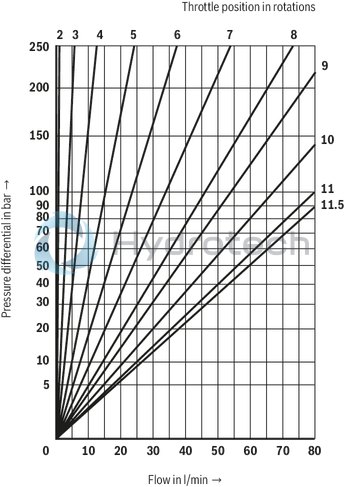

Δp-qV characteristic curves (Version "2Q")

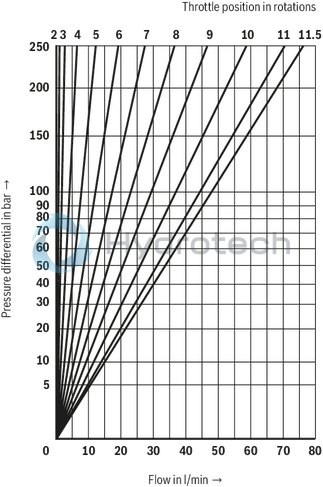

Δp-qV characteristic curves (Version "1Q")

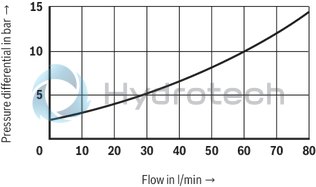

Δp-qV characteristic curves for Z2FS 6 ... via open check valve with closed throttle

Supply throttling

Type Z2FS 6 –…

Type Z2FS 6 B…

Discharge throttling

Type Z2FS 6 –…

Type Z2FS 6 A…

|

➀ |

component side |

|

➁ |

plate side |

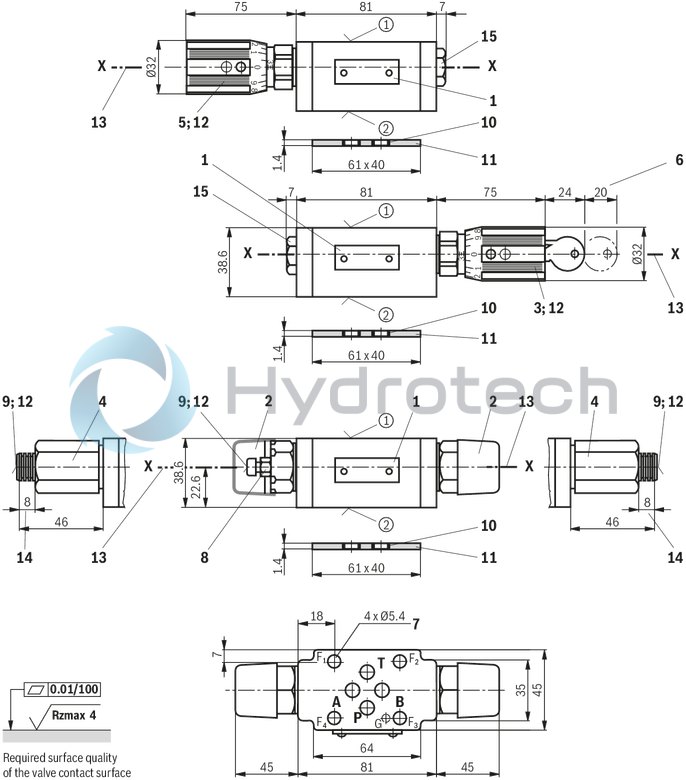

Dimensions in mm

|

➀ |

Component side – porting pattern according to ISO 4401-03-02-0-05 (with locating hole Ø3 x 5 mm deep) |

|

➁ |

plate side – porting pattern according to DIN 24340 form A (without locating hole), or ISO 4401-03-02-0-05 (with locating hole for locking pin ISO 8752-3x8-St; version "/60") |

|

1 |

Name plate |

|

2 |

Adjustment type "2" |

|

3 |

Adjustment type "3" |

|

4 |

Adjustment type "5" |

|

5 |

Adjustment type "7" |

|

6 |

Space required to remove the key |

|

7 |

Valve mounting bores |

|

8 |

Lock nut SW10 |

|

9 |

Setscrew/spindle for flow cross-section adjustment (internal hexagon SW5) |

|

10 |

Same seal rings for ports A, B, P, T |

|

11 |

Seal ring plate |

|

12 |

for all adjustment types: Left rotation = higher flow Right rotation = lower flow |

|

13 |

Modification from discharge to supply control is realized by rotation of the device around axis "X" – "X" |

|

14 |

Stroke |

|

15 |

Plug screw SW22 |

Notice!

Length and tightening torque of the valve mounting screws must be calculated according to the components mounted under and over the sandwich plate valve.

Valve mounting screws (separate order)

4 hexagon socket head cap screws ISO 4762 - M5 - 10.9