BOSCH REXROTH

R900300731

$833.88 USD

- BOSCH REXROTH

- Material:R900300731

- Model:GELENKKOPF CGAS 60 GE.S. KPL.SO4587

Quantity in stock: 2

The Bosch Rexroth GELENKKOPF CGAS 60 GE.S. (R900300731) is a high-quality articulated joint head designed for precision and durability in various applications. This particular model, complete with the order code SO4587, is engineered to provide reliable performance in linkage systems where angular misalignment may occur. The CGAS 60 GE.S. is constructed to withstand significant mechanical stress, making it suitable for dynamic load conditions and pivotal movements within a broad range of operating environments. This model features robust materials that ensure longevity and consistent operation even under demanding conditions. The precise manufacturing standards of Bosch Rexroth are evident in this component's design, which ensures compatibility with other parts and systems for seamless integration into your machinery. The articulated joint head is commonly utilized in areas such as automation, robotics, and motion control applications where precise movement and alignment are critical. The capabilities of the GELENKKOPF CGAS 60 GE.S. extend to its ease of installation and maintenance, providing an efficient solution for system upgrades or replacements. Its design takes into account the need for minimal downtime in industrial settings, enabling quick changeover procedures without compromising on performance or safety. In summary, the Bosch Rexroth GELENKKOPF CGAS 60 GE.S., identified by Material Number R900300731 and specified with order code SO4587, represents a key component in facilitating accurate and smooth articulation within complex machinery setups. It stands as a testament to Bosch Rexroth's commitment to quality engineering and compatibility across various mechanical applications.

For applications outside these parameters, please consult us!

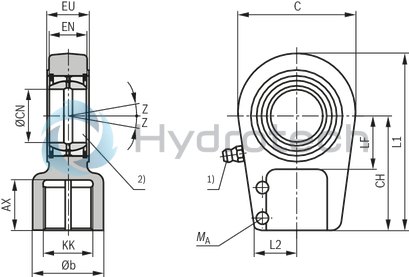

Dimensions: Swivel head CGAS (clampable)

| 1) | Lubricating nipple, cone head form A according to DIN 71412; not applicable to spherical bearing, maintenance-free "A" |

| 2) |

Related bolt Ø m6 Related bolt -Ø j6 for maintenance-free spherical bearing |

Dimensions: Swivel head CGAS (clampable)

|

ØAL |

Type |

Suitable for series |

AX |

Øb |

C |

CH |

ØCN |

EN |

EU |

KK 2) |

L1 |

L2 |

LF |

Z 2) |

Clamping screw |

MA 2) 3) |

m 4) |

C0 5) |

Fadm 6) |

|||

|

|

|

|

min. |

max. |

max. |

|

1) |

|

|

|

|

|

|

max. |

max. |

min. |

|

ISO 4762-10.9 |

|

|

|

|

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

° |

Nm |

kg |

kN |

kN |

||||

| 40 | CGAS 25 |

CDH1 CGH1 CSH1 - - - - |

30 | 28 | 56 | 65 | 25 |

0 - 0.01 |

20 |

0 - 0.12 |

23 |

0 - 0.4 |

M18 x 2 | 95 | 24 | 25 | 7 ... 8 | M8 | 30 | 0.65 | 82 | 27.1 |

| 40 | CGAS 30 |

CDH3 CGH3 CSH3 - - - - |

35 | 34 | 64 | 75 | 30 |

0 - 0.01 |

22 |

0 - 0.12 |

28 |

0 - 0.4 |

M24 x 2 | 109 | 28 | 30 | 6 ... 7 | M8 | 30 | 1 | 122 | 40.3 |

| 50 |

CDH1 CGH1 CSH1 - - - - |

35 | 34 | 64 | 75 | 30 |

0 - 0.01 |

22 |

0 - 0.12 |

28 |

0 - 0.4 |

M24 x 2 | 109 | 28 | 30 | 6 ... 7 | M8 | 30 | 1 | 122 | 40.3 | |

| 50 | CGAS 35 |

CDH3 CGH3 CSH3 - - - - |

46 | 46 | 78 | 90 | 35 |

0 - 0.012 |

25 |

0 - 0.12 |

30 |

0 - 0.4 |

M30 x 2 | 132 | 36 | 40 | 6 ... 7 | M10 | 59 | 1.5 | 177 | 58.4 |

| 63 |

CDH1 CGH1 CSH1 - - - - |

46 | 46 | 78 | 90 | 35 |

0 - 0.012 |

25 |

0 - 0.12 |

30 |

0 - 0.4 |

M30 x 2 | 132 | 36 | 40 | 6 ... 7 | M10 | 59 | 1.5 | 177 | 58.4 | |

| 63 | CGAS 40 |

CDH3 CGH3 CSH3 - - - - |

56 | 57 | 94 | 105 | 40 |

0 - 0.012 |

28 |

0 - 0.12 |

35 |

0 - 0.4 |

M39 x 3 | 155 | 39 | 44 | 7 | M12 | 100 | 2.4 | 287 | 94.7 |

| 80 |

CDH1 CGH1 CSH1 - - - - |

56 | 57 | 94 | 105 | 40 |

0 - 0.012 |

28 |

0 - 0.12 |

35 |

0 - 0.4 |

M39 x 3 | 155 | 39 | 44 | 7 | M12 | 100 | 2.4 | 287 | 94.7 | |

| 80 | CGAS 50 |

CDH3 CGH3 CSH3 - - - - |

76 | 70 | 116 | 135 | 50 |

0 - 0.012 |

35 |

0 - 0.12 |

40 |

0 - 0.4 |

M50 x 3 | 198 | 45 | 55 | 6 ... 7 | M12 | 100 | 4.8 | 422 | 139.3 |

| 100 |

CDH1 CGH1 CSH1 - - - - |

76 | 70 | 116 | 135 | 50 |

0 - 0.012 |

35 |

0 - 0.12 |

40 |

0 - 0.4 |

M50 x 3 | 198 | 45 | 55 | 6 ... 7 | M12 | 100 | 4.8 | 422 | 139.3 | |

| 100 | CGAS 60 |

CDH3 CGH3 CSH3 - - - - |

96 | 87 | 130 | 170 | 60 |

0 - 0.015 |

44 |

0 - 0.15 |

50 |

0 - 0.4 |

M64 x 3 | 240 | 59 | 65 | 6 ... 7 | M16 | 250 | 8.6 | 522 | 172.3 |

| 125 |

CDH1 CGH1 CSH1 - - - - |

96 | 87 | 130 | 170 | 60 |

0 - 0.015 |

44 |

0 - 0.15 |

50 |

0 - 0.4 |

M64 x 3 | 240 | 59 | 65 | 6 ... 7 | M16 | 250 | 8.6 | 522 | 172.3 | |

| 125 | CGAS 70 |

CDH3 CGH3 CSH3 - - - - |

112 | 111 | 154 | 195 | 70 |

0 - 0.015 |

49 |

0 - 0.15 |

55 |

0 - 0.4 |

M80 x 3 | 279 | 70 | 75 | 6 | M16 | 250 | 12.2 | 707 | 233.3 |

| 140 |

CDH1 CGH1 CSH1 - - - - |

112 | 111 | 154 | 195 | 70 |

0 - 0.015 |

49 |

0 - 0.15 |

55 |

0 - 0.4 |

M80 x 3 | 279 | 70 | 75 | 6 | M16 | 250 | 12.2 | 707 | 233.3 | |

| 140 | CGAS 80 |

CDH3 CGH3 CSH3 - - - - |

122 | 129 | 176 | 210 | 80 |

0 - 0.015 |

55 |

0 - 0.15 |

60 |

0 - 0.4 |

M90 x 3 | 305 | 85 | 80 | 6 | M20 | 490 | 18.4 | 870 | 287.1 |

| 160 |

CDH1 CGH1 CSH1 - - - - |

122 | 129 | 176 | 210 | 80 |

0 - 0.015 |

55 |

0 - 0.15 |

60 |

0 - 0.4 |

M90 x 3 | 305 | 85 | 80 | 6 | M20 | 490 | 18.4 | 870 | 287.1 | |

| 160 | CGAS 90 |

CDH3 CGH3 CSH3 - - - - |

142 | 153 | 211 | 250 | 90 |

0 - 0.02 |

60 |

0 - 0.2 |

65 |

0 - 0.4 |

M100 x 3 | 366 | 91 | 90 | 5 | M20 | 490 | 31.6 | 1284 | 423.7 |

| 180 |

CDH1 CGH1 CSH1 - - - - |

142 | 153 | 211 | 250 | 90 |

0 - 0.02 |

60 |

0 - 0.2 |

65 |

0 - 0.4 |

M100 x 3 | 366 | 91 | 90 | 5 | M20 | 490 | 31.6 | 1284 | 423.7 | |

| 180 | CGAS 100 |

CDH3 CGH3 CSH3 - - - - |

152 | 170 | 230 | 275 | 100 |

0 - 0.02 |

70 |

0 - 0.2 |

70 |

0 - 0.4 |

M110 x 4 | 400 | 95 | 105 | 7 | M20 | 490 | 34 | 1460 | 481.8 |

| 200 |

CDH1 CGH1 CSH1 - - - - |

152 | 170 | 230 | 275 | 100 |

0 - 0.02 |

70 |

0 - 0.2 |

70 |

0 - 0.4 |

M110 x 4 | 400 | 95 | 105 | 7 | M20 | 490 | 34 | 1460 | 481.8 | |

| 200 | CGAS 110 |

CDH3 CGH3 CSH3 - - - - |

162 | 180 | 264 | 300 | 110 |

0 - 0.02 |

70 |

0 - 0.2 |

80 |

0 - 0.4 |

M120 x 4 | 443 | 106 | 115 | 6 | M24 | 840 | 44 | 2024 | 667.9 |

| 220 |

CDH1 CGH1 CSH1 CDH3 CGH3 CSH3 - |

162 | 180 | 264 | 300 | 110 |

0 - 0.02 |

70 |

0 - 0.2 |

80 |

0 - 0.4 |

M120 x 4 | 443 | 106 | 115 | 6 | M24 | 840 | 44 | 2024 | 667.9 | |

| 250 |

CDH1 CGH1 CSH1 - - - - |

162 | 180 | 264 | 300 | 110 |

0 - 0.02 |

70 |

0 - 0.2 |

80 |

0 - 0.4 |

M120 x 4 | 443 | 106 | 115 | 6 | M24 | 840 | 44 | 2024 | 667.9 | |

| 250 | CGAS 120 |

CDH3 CGH3 CSH3 - - - - |

192 | 210 | 340 | 360 | 120 |

0 - 0.02 |

85 |

0 - 0.2 |

90 |

0 - 0.4 |

M150 x 4 | 540 | 122 | 140 | 6 | M24 | 840 | 75 | 2970 | 980.1 |

| 280 |

CDH1 CGH1 CSH1 - - - - |

192 | 210 | 340 | 360 | 120 |

0 - 0.02 |

85 |

0 - 0.2 |

90 |

0 - 0.4 |

M150 x 4 | 540 | 122 | 140 | 6 | M24 | 840 | 75 | 2970 | 980.1 | |

| 280 | CGAS 140 |

CDH3 CGH3 CSH3 - - - - |

210 | 230 | 380 | 420 | 140 |

0 - 0.025 |

90 |

0 - 0.25 |

110 |

0 - 0.4 |

M160 x 4 | 620 | 129 | 185 | 7 | M30 | 1700 | 160 | 3350 | 1105.5 |

| 320 |

CDH1 CGH1 CSH1 - - - - |

210 | 230 | 380 | 420 | 140 |

0 - 0.025 |

90 |

0 - 0.25 |

110 |

0 - 0.4 |

M160 x 4 | 620 | 129 | 185 | 7 | M30 | 1700 | 160 | 3350 | 1105.5 | |

| 320 | CGAS 160 |

CDH3 CGH3 CSH3 - - - - |

221 | 260 | 480 | 460 | 160 |

0 - 0.025 |

105 |

0 - 0.25 |

110 |

0 - 0.4 |

M180 x 4 | 710 | 146 | 200 | 8 | M30 | 1700 | 235 | 4302 | 1419.7 |

| 1) |

Related bolt Ø m6 Related bolt -Ø j6 for maintenance-free spherical bearing |

| 2) | Dimensions may differ depending on the manufacturer |

| 3) | MA = tightening torqueThe swivel head must always be screwed against the shoulder of the piston rod. Afterwards, the clamping screws must be tightened with the specified tightening torque. |

| 4) | m = weight of swivel head |

| 5) | C0 = static load rating of the swivel head |

| 6) | Fadm = max. admissible load of the swivel head for increasing or alternating loads |

|

ØAL |

= |

Piston Ø |

Notice:

The specified dimensions are maximum values and may differ depending on the manufacturer.

The following values are excluded: CH, CN, EN, EU, KK