BOSCH REXROTH

R103564020

$232.25 USD

- BOSCH REXROTH

- Material:R103564020

- Model:LSA-A-40-DD

Quantity in stock: 0

The Bosch Rexroth LINEAR-SET LSA-A-40-DD (R103564020) is a high-quality linear motion system designed for precise and smooth linear movement in various applications. This linear set comprises an aluminum housing with an integrated super linear bushing A, which is renowned for its self-aligning feature, providing reliable guidance and reducing installation time. The robust construction includes two external seals that protect internal components from contaminants and extend the system's service life. The product is characterized by its lightweight precision housing made of aluminum, contributing to the overall efficiency of machinery by reducing inertia. It is equipped with a standard shaft diameter 'd' that ensures compatibility with a range of setups. The R103564020 model is capable of withstanding dynamic loads, as indicated by its dynamic load capacity 'C', which should be adjusted based on the direction of loading using specific factors provided for different shaft diameters. With a maximum acceleration 'amax' and a permissible ambient temperature range from -20°C to +80°C, this linear set can perform reliably in diverse environmental conditions. It has been engineered to maintain performance up to a maximum permissible linear speed 'vmax', although higher speeds can result in increased wear on plastic components. The static load rating 'C' further highlights the system's ability to handle loads without deformation or damage when stationary. This model boasts an impressive service life, having undergone tests that demonstrate longevity over significant travel distances without failure. Additionally, the LINEAR-SET LSA-A-40-DD features friction force characteristics that are essential for understanding the resistance encountered during operation when not under radial load. Weighing only 0.7 kg, it provides an optimal balance between strength and weight, making it suitable for precision guides where easy installation and fixed working bore diameter are crucial requirements.

Linear set (aluminum), A-40, with two seals

Linear set (aluminum)

Closed

With super LB A

Shaft diameter d = 40

With two seals

Version: Standard

Unpacked Weight: 1.79 kg

For precision guides with easy installation. Fixed working bore diameter.

| Lightweight precision housing (aluminum) |

| super linear bushing A with self-alignment feature |

| External seals |

| Relubricatable |

| Data Sheet | Download Data Sheet |

| 2D CAD | Download 2D CAD |

| 2D CAD | Download 2D CAD |

| 3D CAD | Download 3D CAD |

| 3D CAD | Download 3D CAD |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Size V | 10 |

| Series | Super A (with self-alignment feature) |

| Footnote friction force FR | Frictional drags generated by linear bushings with integrated wiper seals on two sides when not under radial load. The frictional drags depend on speed and lubrication. |

| Size E1 | 86 |

| Footnote dynamic load capacity C | The load capacities apply for the main direction of loading. If the load direction is not the main direction of loading, the load capacities must be multiplied by the following factors: Ø d 10 to 16: ↩f = 0.82, f0 = 0.86 ↩Ø d 20 to 50: f = 0.82, f0 = 0.78 |

| Size H | 45 |

| Max. acceleration amax | 150 |

| Permissible ambient temperature | -10 °C ... +80 °C |

| Outer diameter D | 62 |

| Size H3 | 14 |

| Breakaway force | 8 |

| Size L3 | 18 |

| Size H4 | 28 |

| Maximum permissible linear speed vmax | 3 |

| Size D | 62 |

| Footnote static load capacity C0 | The load capacities apply for the main direction of loading. If the load direction is not the main direction of loading, the load capacities must be multiplied by the following factors: Ø d 10 to 16: ↩f = 0.82, f0 = 0.86 ↩Ø d 20 to 50: f = 0.82, f0 = 0.78 |

| Size N1 | 44 |

| Static load rating C0 | 5570 |

| Size M | 54 |

| Note: Maximum permissible speed vmax | Speeds of up to 5 m/s possible. Service life is limited by heightened wear to plastic parts. Tests have shown total travel from 50 • 105 m to 100 • 105 m without failure. |

| Friction force | 3 |

| Size A | 108 |

| Productgroup ID | 17 |

| Size N2 | 26 |

| Size E3 | 90 |

| Permissible ambient temperature (max) | |

| Size E2 | 58 |

| Size E4 | 35 |

| Size SW | 6 |

| Permissible ambient temperature (min) | |

| Size S | 10.5 |

| Shaft diameter d | 40 |

| Linear guide type | Linear bushing and shaft |

| Filter for linear bushings and shafts | Linear sets with linear bushings |

| Format of linear bushings | – Closed |

| Dynamic load capacity C | 10070 |

| Size L | 91 |

| Size S2 | 8 |

| Weight | 1.79 |

| Size D1 with tolerance | |

| Size H1 | 90 |

General technical data

|

Ø d |

mm |

10 | 12 | 16 | 20 | 25 | 30 | 40 | 50 |

|

amax |

m/s² |

150 | |||||||

|

vmax 1) |

m/s |

3 | |||||||

|

m |

kg |

0.1 | 0.13 | 0.2 | 0.34 | 0.65 | 0.97 | 1.8 | 3 |

|

FR 2) |

N |

0.5 | 0.8 | 1 | 1.5 | 2 | 2.5 | 3 | 4 |

|

Breakaway force |

N |

1 | 1.5 | 2 | 3 | 4.5 | 6 | 8 | 10 |

|

Shaft radial clearance h6 |

µm |

+ 36 + 9 |

+ 38 + 10 |

+ 43 + 11 |

+ 50 + 12 |

||||

|

Operating conditions |

|||||||||

|

Permissible ambient temperature (min ... max) |

-10 °C ... +80 °C | ||||||||

| 1) | Speeds of up to 5 m/s possible. Service life is limited by heightened wear to plastic parts. Tests have shown total travel from 50 • 105 m to 100 • 105 m without failure. |

| 2) | Frictional drags generated by Linear Bushings with integrated wiper seals on two sides when not under radial load. The frictional drags depend on speed and lubrication. |

Load capacities and load moments

|

Ød |

mm |

10 | 12 | 16 | 20 | 25 | 30 | 40 | 50 |

|

C 1) |

N |

730 | 1020 | 1250 | 2470 | 4820 | 5860 | 10070 | 14730 |

|

C0 1) |

N |

380 | 490 | 620 | 1340 | 2790 | 3570 | 5570 | 8280 |

| 1) | The load ratings apply for the main direction of loading. If the load direction is not the main direction of loading, the load ratings must be multiplied by the following factors: Ø d 10 to 16: f = 0.82, f0 = 0.86 Ø d 20 to 50: f = 0.82, f0 = 0.78 |

| The load ratings are based on a total travel of 100, 00 m. When based on 50 000 m, the values in the table need to be multiplied by 1.26. |

Legend

|

Symbol |

Description |

Unit |

|

Ød |

Shaft diameters |

mm |

|

amax |

Maximum acceleration travel |

m/s2 |

|

C |

Dynamic load capacity |

N |

|

C0 |

Static load capacity |

N |

|

FR |

Friction force |

N |

|

m |

Mass |

kg |

|

vmax |

Maximum permissible speed |

m/s |

Impact of load direction on load rating of closed Linear Bushings

The listed load ratings should be chosen depending on installation in minimum or maximum position and should be based on the calculations. If the load direction is clearly defined and the Linear Bushings can be installed in maximum position, the load ratings Cmax. (dynamic load rating) and C0 max (static load rating) can be used. If aligned installation is not possible or the load direction is not defined, the minimum load ratings must be used.

Reduced load capacity with short stroke

In case of short stroke, the service life of the shaft is less than that of the super Linear Bushing. The load ratings C specified in the tables must therefore be multiplied by the factor f.s .

| 1) | fs = factor |

| 2) | s = movement path |

Reduced load capacity with high load

If the load F on a Super Linear Bushing A is more than F > 0.5 x C, the dynamic load rating C decreases.

Definition of dynamic load ratings

Self-alignment feature

The self-alignment feature in the steel bearing plates and machined ball guide grooves ensure quieter travel. The flow chart shows a comparison with a conventional Linear Bushing. The example is based on a load of 800 N and misalignment of about 8 ft (caused by shaft deflection).

Due to the self-alignment feature, two super Linear Bushings must be used on at least one of the shafts in the guide.

| FR = Frictional drag | |

| s = travel distance | |

| v = travel speed | |

| a) | Super Linear Bushing, A Ød 20 |

| b) | Conventional Linear Bushing, Ød 20 |

| a) | Lubricating hole sealed with plastic cap |

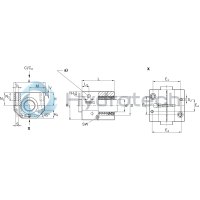

Dimensions

|

Ød |

mm |

10 | 12 | 16 | 20 | 25 | 30 | 40 | 50 |

|

D |

mm |

19 | 22 | 26 | 32 | 40 | 47 | 62 | 75 |

|

A |

mm |

40 | 43 | 53 | 60 | 78 | 87 | 108 | 132 |

|

E1 |

29 mm ±0.15 | 32 mm ±0.15 | 40 mm ±0.15 | 45 mm ±0.15 | 60 mm ±0.15 | 68 mm ±0.15 | 86 mm ±0.15 | 108 mm ±0.2 | |

|

E2 |

20 mm ±0.15 | 23 mm ±0.15 | 26 mm ±0.15 | 32 mm ±0.15 | 40 mm ±0.15 | 45 mm ±0.15 | 58 mm ±0.15 | 50 mm ±0.2 | |

|

E3 |

mm |

31 | 34 | 42 | 50 | 64 | 72 | 90 | 108 |

|

E4 |

mm |

29 | 32 | 35 | 45 | 20 | 30 | 35 | 42 |

|

H |

mm |

16 | 18 | 22 | 25 | 30 | 35 | 45 | 50 |

|

Tolerance for H 1) |

µm |

+ 8 - 16 |

|||||||

|

H1 |

mm |

31.5 | 35 | 42 | 50 | 60 | 70 | 90 | 105 |

|

H3 |

mm |

10 | 11.5 | 14 | 12.5 | ||||

|

H4 |

mm |

10 | 13 | 16 | 20 | 22 | 28 | 37 | |

|

L |

mm |

36 | 39 | 43 | 54 | 67 | 79 | 91 | 113 |

|

L3 |

mm |

10.5 | 11.5 | 13.5 | 15 | 16 | 18 | 22 | |

|

M 1) |

20 mm ±0.01 | 21.5 mm ±0.01 | 26.5 mm ±0.01 | 30 mm ±0.01 | 39 mm ±0.01 | 43.5 mm ±0.01 | 54 mm ±0.01 | 66 mm ±0.01 | |

|

N1 |

mm |

15 | 16.5 | 21 | 24 | 29 | 34 | 44 | 49 |

|

N2 |

mm |

11 | 13 | 18 | 22 | 26 | 34 | ||

|

S 2) |

mm |

4.3 | 5.3 | 6.6 | 8.4 | 10.5 | 13.5 | ||

|

S1 |

M5 | M6 | M8 | M10 | M12 | M16 | |||

|

S2 3) |

mm |

4 | 5 | 6 | 8 | 10 | |||

|

SW |

mm |

2.5 | 3 | 4 | 5 | 6 | 8 | ||

|

V |

mm |

5 | 6.5 | 8 | 10 | 12 | |||

| 1) | Clamped (fastened) in relation to Ø d. |

| 2) | Fixing screws ISO 4762-8.8 |

| 3) | Pin hole centering. |

Radial clearance

The radial clearance values shown in the table have been determined from statistics and correspond to values expected in practice. The adjustable Linear Sets come clamped to an h5 shaft (lower limit) and set to zero clearance.

Vertical dimension

The tolerance values for the vertical dimension "H" for the Linear Sets shown in the table have been determined from statistics and correspond to values expected in practice.

Bolts

We recommend bolts in accordance with ISO 4762-8.8 for fastening the Linear Sets.

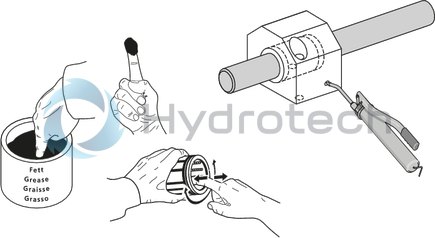

Lubrication

On-shaft relubrication on relubricatable Linear Bushing only until lubricant seeps out.

General mounting instructions

Metal cases for Super Linear Bushings and standard Linear Bushings

Metal cases for Super Linear Bushings and standard Linear Bushings

Galvanized steelCatalog

Instructions

Service

CAD data

Hydraulic-type lube nipple according to DIN 71412 Form A

Hydraulic-type lube nipple according to DIN 71412 Form A

Catalog

Instructions

Service

Funnel-type lube nipple according to DIN 3405 Form A

Funnel-type lube nipple according to DIN 3405 Form A

Catalog

Instructions

Service

Wiper seals for closed-type Super Linear Bushings and Standard Linear Bushings

Wiper seals for closed-type Super Linear Bushings and Standard Linear Bushings

Galvanized metal case Elastomer wiper sealCatalog

Instructions

Service

CAD data