BOSCH REXROTH

R053512210

$40.59 USD

- BOSCH REXROTH

- Material:R053512210

- Model:KUS-B22-MFG

Quantity in stock: 0

The Bosch Rexroth BALL TRANSFER UNIT KUS-B22-MFG (R053512210) is an advanced conveying solution designed to facilitate the easy and smooth movement of heavy loads. This ball transfer unit features a robust reinforced steel housing with a galvanized cover, ensuring durability and resistance to impact loads. The balls are crafted from high-quality antifriction bearing steel, providing reliable performance under demanding conditions. With its felt seal, the KUS-B22-MFG is pre-lubricated for immediate use and offers protection against contaminants, extending the service life of the unit. It has been engineered to operate within a temperature range of -30°C to +70°C, accommodating various environmental conditions. However, for applications exceeding 70°C, units without a felt seal should be employed alongside high-temperature lubricants as per manufacturer guidelines. The unit boasts an outer diameter (D) that allows for maximum permissible linear speeds (vmax), ensuring efficient operation while maintaining stability. Users should note that prolonged use at speeds above 0.5 m/s may result in increased temperatures and reduced lifespan depending on the load applied. Bosch Rexroth has designed this ball transfer unit with a static load rating (C) and dynamic load capacity (Cdyn), indicating its suitability for handling heavy weights while maintaining smooth motion. The product's nominal size and tolerances are meticulously specified to guarantee compatibility with various installation requirements. Weighing in at just 0.4 kg, the KUS-B22-MFG is both lightweight and compact, making it an ideal choice for systems where space is at a premium but performance cannot be compromised. Whether used in material handling systems or as part of a larger conveyor assembly, this ball transfer unit from Bosch Rexroth stands out as a reliable component that can significantly enhance operational efficiency.

Ball transfer units with felt seal – Size 22

Ball transfer unit with reinforced steel housing

Galvanized cover and housing, balls made from anti-friction bearing steel

Size = 22

With felt seal, lubricated

Unpacked Weight: 0.164 kg

| With sheet steel housing |

| Reinforced housing and cover |

| For heavy impact loads |

| Cover and housing galvanized |

| Balls made from antifriction bearing steel 1.3505 |

| Data Sheet | Download Data Sheet |

| 2D CAD | Download 2D CAD |

| 2D CAD | Download 2D CAD |

| 3D CAD | Download 3D CAD |

| 3D CAD | Download 3D CAD |

| Product information | Ball transfer unit with bottom hole on request |

| Maximum operating temperature | |

| Size H | 29.5 |

| Minimum operating temperature | |

| Size h | 9.8 |

| Outer diameter D | 36 |

| Maximum permissible linear speed vmax | 2 |

| Operating temperature | -30 °C ... +100 °C |

| Size D | 36 |

| Size D1 | 45 |

| Tolerance h | |

| Static load rating C0 | 3000 |

| Note: Maximum permissible speed vmax | In case of prolonged periods of use at speeds above 1 m/s, an increase in temperature and reduction in service life is to be expected depending on the load. |

| Size dW | 22.225 |

| Productgroup ID | 17 |

| Size b | 6.2 |

| Footnote permissible operating temperature (min...max) | At temperatures above 100 °C, only bright metal ball transfer units without a felt seal should be used. Make allowance for reduction in load capacity. Use high-temperature lubricant! Follow the manufacturer’s instructions! The existing lubricant oil may have to be washed out. |

| Dynamic load capacity C | 1300 |

| Footnote operating temperature max. | For temperatures over 100°C, only load balls made from bare metal without a felt seal may be used. Take into account the reduction in load capacity. Use high-temperature lubricant! Follow the instructions of the manufacturer! The existing lubricant oil may have to be washed out. |

| Weight | 0.164 |

| Nominal size | 22 |

| Tolerance D |

Technical data

|

Size |

15 | 22 | 30 | 45 | ||

|

C |

N |

500 | 1300 | 2500 | 6000 | 8000 |

|

C0 |

N |

1300 | 3000 | 6000 | 15000 | |

|

vmax 1) |

m/s |

2 | ||||

|

m |

kg |

0.045 | 0.15 | 0.3 | 0.82 | |

|

Operating conditions |

||||||

|

Size |

15 | 22 | 30 | 45 | ||

|

Admissible operating temperature (min ... max) 2) |

-30 °C ... +100 °C | |||||

| 1) | In case of prolonged periods of use at speeds above 1 m/s, an increase in temperature and reduction in service life needs to be reckoned with depending on the load. |

| 2) | At temperatures above 100 °C, only bright metal load balls without a felt seal should be used. Make allowance for reduction in load capacity. Use high-temperature lubricant! Follow the manufacturer’s instructions! The existing lubricant oil may have to be washed out. |

At temperatures above 100 °C, only bright metal ball transfer units without a felt seal should be used. Note the reduction in load capacity! Use high-temperature lubricant! Follow the manufacturer’s instructions! The existing lubricant oil may have to be washed out.

Temperature factor

|

Temperature (°C) |

Temperature factor ft |

|

125 |

0,9 |

|

150 |

0,8 |

|

175 |

0,7 |

|

200 |

0,5 |

The load capacity must be multiplied by the temperature factor.

Legend

|

Symbol |

Description |

Unit |

Picture |

|

C |

Dynamic load capacity |

N |

|

|

C0 |

Static load capacity |

N |

|

|

vmax |

Conveying speed |

m/s |

|

|

m |

Mass |

kg |

Technical data

Applications

General-purpose machines Feed tables for sheet-metal working machines Fixtures for press brakes Feed devices for machining centers Drilling tables and motor-driven supporting tables Assembly aids in the manufacture of large engines and motors Construction of special-purpose machines Aerospace industry Beverages and stone-processing industries Not suitable for use under water

Conveyor systems

Ball transfer tables, turntables and switches for sorting and distribution systems Crossover sections of continuous conveyors Baggage sorting systems at airports Transport of steel tubes and pipes Lifting platforms

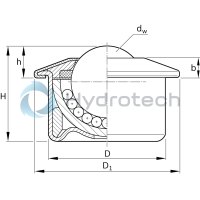

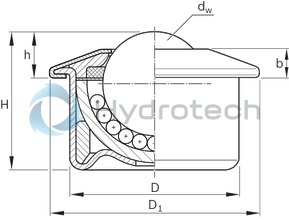

Dimensions

|

Size |

dw |

D |

Tolerance for D |

D1 |

h |

Tolerance for h |

H |

b |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

| 15 | 15.875 | 24 | ± 0.065 | 31 | 9.5 | ± 0.2 | 21.5 | 5.5 |

| 22 | 22.225 | 36 | ± 0.08 | 45 | 9.8 | 29.5 | 6.2 | |

| 30 | 30.162 | 45 | 55 | 13.8 | ± 0.3 | 37.5 | 8.2 | |

| 45 | 44.45 | 62 | ± 0.095 | 75 | 19 | ± 0.4 | 53.7 | 10.5 |

| 1) | Press fit |

| 2) | with tolerance ring |

| 3) | Gluing in |

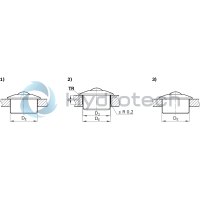

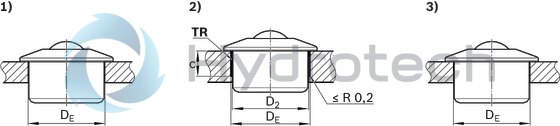

Installation dimensions

|

Size |

Press fit |

with tolerance ring |

Gluing in |

||||||||||

|

2 mm sheet steel 5 Mm aluminum |

16 mm wood |

Part number |

D2 |

Tolerance for D2 |

DE |

Tolerance for DE |

c |

Tolerance for c |

DE |

Tolerance for DE |

|||

|

DE |

Tolerance for DE |

DE |

Tolerance for DE |

Tolerance ring |

|||||||||

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

||

| 15 | 23.95 | + 0.05 | 23.9 | + 0.05 | R081002403 1) | 24.2 | + 0.2 | 25.7 | + 0.2 | 7.1 | + 0.2 | 24.1 | + 0.2 |

| 22 | 35.9 | + 0.05 | 35.85 | + 0.07 | R081003605 1) | 36.2 | 37.7 | 12.1 | 36.1 | ||||

| 30 | 44.85 | + 0.05 | 44.8 | + 0.1 |

R081004501 2) R081004551 2) |

45.2 | 46.7 | 45.1 | |||||

| 45 | 61.83 | + 0.07 | 61.8 | + 0.1 | R081006203 1) | 62.3 | 64.1 | + 0.3 | 15.1 | 62.2 | |||

| + 0.07 | + 0.1 | ||||||||||||

| 1) | made from spring strip 1.1248, alternatively 1.8159 |

| 2) | R081004501 made from spring strip 1.1248, alternatively 1.8159; R081004551 made from corrosion-resistant steel 1.4310 |