BOSCH REXROTH

R978879535

$621.94 USD

- BOSCH REXROTH

- Material:R978879535

- Model:4WH 6 D5X/5 SO43A-909

Quantity in stock: 0

The Bosch Rexroth 4WH 6 D5X/5 SO43A-909 (R978879535) is a high-performance directional spool valve designed to control the start, stop, and direction of fluid flow with precision. This valve falls under the WH series and is characterized by its robust housing, hydraulic actuation cylinders, control spool, and return springs. The radial positioning of the ports for control ensures efficient fluid dynamics within the system. Equipped with a throttle insert in channel P, the valve can be regulated to handle operating conditions that may produce flows exceeding its performance limit during switching processes. This feature enhances the valve's adaptability to various operational demands. The model code indicates specific features such as being without spring return but with a detent (..OF.. version), allowing each spool position to be locked securely. This capability is particularly useful for applications where maintaining a constant flow direction is critical even when deenergized. For configurations that do not require defined spool positions when deenergized (..O.. version), this valve can be utilized without return springs and detents. It allows for flexible integration into systems where variable flow directions are necessary or where manual adjustment is preferred. The Bosch Rexroth 4WH 6 D5X/5 SO43A-909 also supports hydraulic operation methods and adheres to standard porting patterns according to DIN form A without locating holes and ISO with locating holes, ensuring compatibility with various industrial requirements. The availability of inductive position switches and proximity sensors offers contactless operation options for enhanced performance monitoring. With its size component series X, this direct-operated directional spool valve can withstand maximum operating pressures up to specified bar levels while handling maximum flow rates measured in liters per minute, making it suitable for a wide range of high-demand applications.

General information

Valves of type WH are fluidically actuated directional spool valves. They control the start, stop and direction of a flow.

The directional valves basically consist of housing (1), one or two actuation elements (2) (hydraulic actuation cylinder), control spool (3) and one or two return springs (4). The ports for the control are positioned radially (5).

When de-energized, the control spool (3) is held in the central position or in the initial position by the return springs (4) (except impulse spool).

The control spool (3) is moved to the desired spool position by means of the actuation elements.

Throttle insert

The use of a throttle insert is required when due to prevailing operating conditions, flows can occur during the switching processes, which exceed the performance limit of the valve.

It is inserted in channel P of the directional valve.

Typ 4WH 6 E5X/...

Without spring return, with detent,

version ..OF/..

Directional valves with hydraulic actuation are also available as a 2-spool position valve with detent (7). If actuation elements with detent are used, each spool position can be locked.

Without spring return,

version ..O/..

If actuation elements without return springs and without detent are used, there is no defined spool position in the de-energized state.

Type 4WP 6 C6X/OF/N...

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

||

|

W |

H |

no code |

6 |

5X |

/ |

J |

/ |

* |

|

01 |

3 main ports |

3 |

|

4 main ports |

4 |

|

|

02 |

Directional valve |

W |

|

Type of actuation |

||

|

03 |

hydraulic |

H |

|

04 |

Ports radial |

no code |

|

05 |

Size 6 |

6 |

|

06 |

Spool symbol, e. g. C, E, EA, EB etc. 2) |

|

|

07 |

Component series 50 … 59 (50 … 59: unchanged installation and connection dimensions) |

5X |

|

08 |

With spring return |

no code |

|

Without spring return |

O |

|

|

Without spring return with detent |

OF |

|

|

09 |

Improved corrosion protection 3) |

J |

|

10 |

Without manual override |

no code |

|

With manual override |

N3) |

|

|

Spool position monitoring 7) |

||

|

11 |

Without position switch |

no code |

|

Monitored spool position "a" |

QMAG24 |

|

|

Monitored spool position "b" |

QMBG24 |

|

|

Monitored rest position |

QM0G24 |

|

|

12 |

Without throttle insert |

no code |

|

Throttle Ø 0.8 mm |

B086) |

|

|

Throttle Ø 1.0 mm |

B106) |

|

|

Throttle Ø 1.2 mm |

B126) |

|

|

Seal material |

||

|

13 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

Observe compatibility of seals with hydraulic fluid used. (Other seals upon request) |

||

|

Clamping length |

||

|

14 |

42 mm (standard) |

no code |

|

22 mm |

Z |

|

|

15 |

Without locating hole |

no code |

|

With locating hole |

/605) |

|

|

With locating hole and locking pin ISO 8752-3x8-St |

/62 |

|

|

16 |

Further details in the plain text |

* |

Preferred types and standard units are specified in the EPS (standard price list).

|

Switching positions |

|||

|

2 |

3 |

Type WH |

|

|

no code |

● |

● |

● |

|

O |

● |

● |

|

|

OF |

● |

● |

|

|

● = available |

|||

| 1) Not with version “N” | |

| 2) For symbols and example, see Symbols and Types of actuation | |

| 3) The external parts made of metal are galvanized, treated with an anti-corrosion agent or made of stainless steel. This design is also suitable for on-wall applications. | |

| 5) Locking pin ISO 8752-3 x 8-St, material no. R900005694, separate order | |

| 6) Use if volume flow > performance limits of the valve, effective in channel P. | |

| 7) Not for version “J” |

general

|

Size |

6 | ||

|

Weight (approx.) |

Valve with one actuation cylinder |

kg |

2 |

|

Valve with two actuation cylinders |

kg |

2.2 | |

|

Installation position 1) |

any | ||

|

Ambient temperature range |

NBR seals |

°C |

-30 … +80 |

|

FKM seals |

°C |

-20 … +80 | |

| 1) | With version ../O.. (A, C and D) : horizontal |

hydraulic

|

Size |

6 | ||

|

Maximum operating pressure |

Port P |

bar |

315 |

|

Port A |

bar |

315 | |

|

Port B |

bar |

315 | |

|

Port T 1) |

bar |

160 | |

|

Maximum flow |

l/min |

60 | |

|

Flow cross-section (spool position 0) |

Symbol Q |

mm2 |

approx. 6 % of nominal cross-section |

|

Symbol W |

mm2 |

approx. 3 % of nominal cross-section | |

|

Minimum pilot pressure 2) |

bar |

6 | |

|

Maximum pilot pressure |

bar |

200 | |

|

Pilot volume |

cm³ |

1.23 | |

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-30 … +80 |

|

FKM seals |

°C |

-20 … +80 | |

|

Viscosity range |

mm²/s |

2.8 … 500 | |

|

Maximum admissible degree of contamination of the hydraulic fluid 3) |

Class 20/18/15 according to ISO 4406 (c) | ||

|

Maximum switching frequency |

Hz |

2 | |

| 1) | With symbols A and B, port T must be used as leakage oil connection if the operating pressure exceeds the admissible tank pressure. |

| 2) | 6 ... 10 bar > tank pressure, performance limits dependent on the minimum pilot pressure, see chapter "Diagrams/characteristic curves", section "Performance limits" |

| 3) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oil |

HL, HLP |

FKM, NBR |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HEES (synthetic esters) |

FKM |

VDMA 24568 |

|

HETG (rape seed oil) |

FKM, NBR |

|||

|

Soluble in water |

HEPG (polyglycols) |

FKM |

VDMA 24568 |

|

|

Other hydraulic fluids on request |

||||

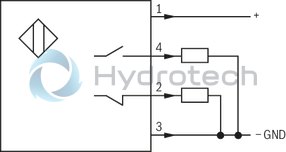

Inductive position switch type QM: electrical connection

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

Connection voltage (DC voltage) |

V |

24 | ||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

For applications outside these parameters, please consult us!

(measured with HLP46, ϑOil = 40 ±5 °C)

Δp-qV characteristic curves

|

Symbol |

Direction of flow |

|||

|

P-A |

P-B |

A-T |

B-T |

|

|

A |

3 |

3 |

– |

– |

|

B |

3 |

3 |

– |

– |

|

C |

1 |

1 |

3 |

1 |

|

D |

5 |

5 |

3 |

3 |

|

E |

3 |

3 |

1 |

1 |

|

F |

1 |

3 |

1 |

1 |

|

G |

6 |

6 |

9 |

9 |

|

H |

2 |

4 |

2 |

2 |

|

J |

1 |

1 |

2 |

1 |

|

L |

3 |

3 |

4 |

9 |

|

M |

2 |

4 |

3 |

3 |

|

P |

3 |

1 |

1 |

1 |

|

Q |

1 |

1 |

2 |

1 |

|

R |

5 |

5 |

4 |

– |

|

T |

10 |

10 |

9 |

9 |

|

U |

3 |

3 |

9 |

4 |

|

V |

1 |

2 |

1 |

1 |

|

W |

1 |

1 |

2 |

2 |

|

Y |

5 |

5 |

3 |

3 |

|

Further characteristic curves: |

|

|

7 |

Symbol “R” in switching position “b” (B → A) |

|

8 |

Symbol “G” and “T” in central position (P → T) |

|

9 |

Symbol “H” in central position (P → T) |

Minimum pilot pressure dependent on the tank pressure

At a higher tank pressure, the minimum pilot pressure has to be increased according to this diagram.

Performance limits

(measured with HLP46, ϑOil = 40 ±5 °C)

Notice!

The switching function of the valves is independent from the filtration due to the adhesive effect. To achieve the specified admissible flow values, a full flow filtration with 25 μm is recommended. The flow forces acting within the valves also influence the flow performance.

With 4-way directional valves, the specified flow data are therefore valid for normal operation with 2 directions of flow (e. g. from P to A and simultaneous return flow from B to T).

If there is only one direction of flow, the admissible flow may be significantly lower in critical cases (e. g. if a 4-way directional valve is used as a 3-way directional valve due to blocked port A or B).

|

Pilot pressure 6 bar > tank pressure |

||

|

Spring return |

Characteristic curve |

Symbol |

|

“no code” |

1 |

A, B |

|

2 |

C, D, Y |

|

|

3 |

E, J, L, U, M, Q, V, W, E1- |

|

|

4 |

F, P |

|

|

5 |

T |

|

|

6 |

G, H |

|

|

7 |

R |

|

|

../O.. |

8 |

A, C, D |

|

../OF.. |

||

|

Pilot pressure 10 bar > tank pressure |

||

|

Spring return |

Characteristic curve |

Symbol |

|

“no code” |

1 |

A, B |

|

8 |

C, D, Y, E, G, H, J, L, U, M, Q, V, W, E1- |

|

|

9 |

F, P

|

|

|

10 |

R |

|

|

11 |

T |

|

|

../O.. |

8 |

A, C, D |

|

../OF.. |

||

Attention!

Caution in conjunction with differential cylinders due to pressure intensification!

| 1) |

Example: – Symbol E with spool position "a" → ordering code ..EA.. – Symbol E with spool position “b” → ordering code ..EB.. |

| 2) | Symbol E1-: P → A/B pre-opening |

|

Ordering code |

Type of actuation |

||

|

Symbol |

Actuation side |

Spool return |

|

|

A, C, D |

|

||

|

../O.. |

|

||

|

../OF.. |

|

||

|

B, Y |

|

||

|

E, F G, H J, L M, P Q, R T, U V, W |

a = A |

|

|

|

b = B |

|

||

|

|||

Dimensions in mm

|

|

Required surface quality of the valve contact surface |

|

L1 |

L2 |

L3 |

L4 |

L5 |

|

mm |

mm |

mm |

mm |

mm |

| 22.5 | 64.5 | 48 | 90 | 138 |

|

1 |

Valve with 2 spool positions and 2 actuation cylinders |

|

Valve with 3 spool positions and 2 actuation cylinders |

|

|

2 |

Actuation cylinder “a” |

|

3 |

Actuation cylinder “b” |

|

4 |

Cover for valve with 1 actuation cylinder (2 spool positions) |

|

5 |

Same seal rings for ports A, B, P, T |

|

6 |

Name plate |

|

7 |

Porting pattern according toISO 4401-03-02-0-05 (with locating hole for locking pin ISO 8752-3x8-St, material no. R900005694, separate order) |

|

8 |

Connection |

|

9 |

Port with version “WHZ” |

|

11 |

Alternative clamping length (): 22 mm |

Subplates according to data sheet 45052 (separate order)

(without locating hole)

G 341/01 (G1/4)

G 342/01 (G3/8)

G 502/01 (G1/2)

(with locating hole)

G 341/60 (G1/4)

G 342/60 (G3/8)

G 502/60 (G1/2)

G 341/12 (SAE-6)1)

G 342/12 (SAE-8)1)

G 502/12 (SAE-10)1)

1) On request

Valve mounting screws (separate order)

Clamping length 42 mm:4 hexagon socket head cap screws, metric

ISO 4762-M5 x 50-10.9-flZn-240h-L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = 7 Nm ± 10 %,

material no. R913000064

or

4 hexagon socket head cap screws

ISO 4762-M5 x 50-10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 8.1 Nm ± 10 %

4 hexagon socket head cap screws UNC

10-24 UNC x 2″ ASTM-A574

(friction coefficient μtotal = 0.19 to 0.24);

tightening torque MA = 11 Nm± 15 %,

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 8 Nm ± 10 %,

material no. R978800693

Clamping length 22 mm:4 hexagon socket head cap screws, metric

ISO 4762-M5 x 30-10.9-flZn-240h-L

(friction coefficient μtotal= 0.09 to 0.14);

tightening torque MA = 7 Nm ± 10 %,

material no. R913000316

or

4 hexagon socket head cap screws

ISO 4762-M5 x 30-10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 8.1 Nm± 10 %

4 hexagon socket head cap screws UNC

10-24 UNC x 1 1/4 ″

(friction coefficient μtotal = 0.19 to 0.24);

tightening torque MA = 11 Nm± 15 %,

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = 8 Nm± 10 %,

material no. R978802879

Spool position monitoring

Inductive position switch type QM

Dimensions in mm

| 1) | For dimensions, see valve dimensions |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.