BOSCH REXROTH

R901342024

$416.00 USD

- BOSCH REXROTH

- Material:R901342024

- Model:HM 20-2X/100-C-K35

Quantity in stock: 0

The Bosch Rexroth HM 20-2X/100-C-K35-N (R901342024) is a high-performance pressure transducer designed for dynamic pressure control in hydraulic systems. This sensor excels in transforming measured pressure into a linear, analog electrical signal of 4-20 mA, suitable for accurate monitoring and regulation tasks. It features a robust design with all components that come into contact with media being constructed from durable stainless steel, ensuring longevity and reliability even in harsh conditions. The HM 20-2X/100-C-K35-N is equipped with a thin film measuring cell that provides high measurement accuracy of less than ±0.5% FS and excellent non-repeatability of less than ±0.1%. It has been engineered to offer rapid signal rise times below 2 ms, which is critical for systems requiring fast response times. The device can handle pressure ranges up to 600 bar and includes an integrated throttle element in the pressure channel to stabilize the signal. For ease of electrical connection, this model includes a connector pole with M12x1 A-coding according to EN standards. The absence of an onboard display streamlines the unit's profile while the supply voltage requirement is standard at 24 VDC. With a weight of just 0.6 kg and NBR seals, it is designed for straightforward installation and maintenance. Safety features are paramount; this transducer boasts excellent overload protection, reversed polarity protection, overvoltage protection, and short-circuit protection. Its operational safety is further enhanced by its high bursting pressure capability. The HM 20-2X/100-C-K35-N operates efficiently within a wide temperature range and meets various conformity standards including CE, UL, UKCA, RoHS, and DNV marine approval for variants with current output. The component series X ensures compatibility across different applications with maximum operating pressures up to 600 bar and various pressure ratings available (from 50 bar up to 600 bar). This transducer is cULus-listed, confirming its compliance with North American safety standards.

Pressure transducer with analog output 4 … 20 mA, pressure range 0 … 100 bar, connector 4-pole M12x1 A-coded, throttle element

Short signal rise time

Unpacked Weight: 0.063 kg

Pressure transducers are used to monitor and control hydraulic pressures. They transform the measured pressure into a normalized, linear, electrical output signal.

| Thin film measuring cell |

| Analog output: 4 … 20 mA |

| Hydraulic connection G1/4 |

| Throttle element in the pressure channel |

| Connector 4-pole, M12x1, A-coded |

| Component series 2X |

| Data Sheet | Download Data Sheet |

| 3D CAD | Download 3D CAD |

| 3D CAD | Download 3D CAD |

| Max. pressure | 100 |

| Electrical connection description | Connector, 4-pole, M12 x 1, coding A according to EN 61076-2-101 |

| Productgroup ID | 9,10,11,12,13,14 |

| Conformity description | CE – electro-magnetic compatibility 2014/30/EU RoHS Directive 2011/65/EU |

| Display | no |

| Connection diagram | Male thread G1/4 |

| Supply voltage | 24 VDC |

| Weight | 0.063 |

| Seals | NBR |

| Output signal | 4 … 20 mA |

| Hydraulic fluid | HL,HLP,HFC,Nitrogen (up to 300 bar) |

| Conformity | CE,UL,UKCA,RoHS,DNV |

|

01 |

02 |

03 |

04 |

05 |

06 |

||||

|

HM20 |

– |

2X |

/ |

– |

– |

K35 |

|

01 |

Pressure transducer |

HM20 |

|

02 |

Component series 20 ... 29 (20 ... 29: unchanged installation dimensions and pin assignments) |

2X |

|

03 |

10 bar |

10 |

|

50 bar |

50 |

|

|

100 bar |

100 |

|

|

160 bar |

160 |

|

|

250 bar |

250 |

|

|

315 bar |

315 |

|

|

400 bar |

400 |

|

|

630 bar1) |

630 |

|

|

04 |

Current output 4 to 20 mA 2) |

C |

|

Voltage output 0.1 to 10 V |

H |

|

|

05 |

Connector, 4-pole, M12x1 |

K35 |

|

06 |

Without throttle element |

ohne Bez. |

|

Throttle element (corresponds to 0.3 mm nozzle) 3), 4) |

N |

| 1) | Only available with throttle element |

| 2) | With marine approval DNV-GL |

| 3) | Only available for versions with 250, 315, 400 and 630 bar |

| 4) | Highly dynamic effects in like pressure peaks or cavitation in hydraulic systems may damage the measuring cell. For these applications, devices with integrated throttle element [version "-N"] in the process interface have to be used. |

|

Replacement seal ring |

|

|

Designation |

Part number |

|

Seal ring NBR |

R900012467 |

Cable sets or mating connectors are not included in the scope of delivery; please order separately.

General

|

Component series |

2X |

Eingangsgrößen

|

Operating voltage 1) |

US |

16 … 36 VDC | ||||||||

|

Residual ripple |

UPP |

2.5 V (40 to 400 Hz) | ||||||||

|

Maximum current consumption 2) |

Imax |

mA |

≤ 12 | |||||||

|

Isolation resistance |

R |

MΩ |

> 100 (500 VDC) | |||||||

|

Pressure measuring ranges |

pN |

bar |

10 | 50 | 100 | 160 | 250 | 315 | 400 | 630 |

| 1) | With cULus: max. of 30 VDC is admissible |

| 2) | With voltage output |

Output parameters

|

Output signal |

admissible load |

Current |

ISig |

4 … 20 mA, RA = (US - 8.5 V) / 0.0215 A with RA in Ω and US in V | |

|

Voltage |

USig |

0.1 … 10 V, RA > 2 kΩ | |||

|

Setting time (10 ... 90 %) |

t |

ms |

< 1 | ||

|

Accuracy class 1) |

% |

< 0.5 | |||

|

Temperature coefficient |

Zero point and range |

< 0.1 % / 10 K | |||

|

Hysteresis 2) |

% |

< 0.15 | |||

|

Long-term drift (1 year) under reference conditions |

% |

< 0.1 | |||

| 1) | Related to the complete measurement range, including non-linearity, hysteresis, zero point and end value deviation (corresponds to the measuring deviation according to IEC 61298-2) |

| 2) | Related to the temperature range -20 … 80 °C |

Ambient conditions

|

Ambient temperature range |

ϑ |

°C |

-40 … +85 |

|

Storage temperature range |

ϑ |

°C |

-40 … +100 |

|

Hydraulic fluid temperature range |

ϑ |

°C |

-40 … +90 |

Other characteristics

|

Pressure port 1) |

G1/4 according to DIN 3852 form E, seal ring according to DIN 3869-14 | |||

|

Material |

Throttle |

1.4305 | ||

|

Housing |

V4A (1.4404), PEI, HNB | |||

|

in contact with the medium |

1.4542, 1.4305, NBR | |||

|

Pressure media 2) |

HL, HLP, HFC, nitrogen, others upon request | |||

|

Tightening torque range |

Measurement ranges > 400 bar |

MA |

Nm |

20 … 25 |

|

Measurement ranges ≥ 400 bar |

MA |

Nm |

25 … 30 | |

|

Anschlussart |

4-pole M12 connector at the housing | |||

|

Type of protection according to EN 60529 |

IP65 / IP67 with mating connector correctly mounted and locked | |||

|

Weight |

m |

kg |

0.06 | |

|

Life cycle |

60 million load cycles or 60000 h | |||

|

Admissible shock and vibration loads according to DIN EN 60068-2-27 |

15 g / 11 ms / 3 axes | |||

|

Sine test according to DIN EN 60068-2-6:2008 |

10 ... 2000 Hz / maximum 10 g / 10 cycles / 3 axes | |||

|

Noise test according to DIN EN 60068-2-64 |

20 … 2000 Hz / 14 g RMS / 42 g peak / 24 h / 3 axes | |||

|

Electro-magnetic compatibility |

EMC EN 61000-4-2 ESD |

4 kV CD / 8 kV AD with BWK B | ||

|

EMC EN 61000-4-3 HF radiated |

10 V / m (80 ... 2700 MHz) with BWK A | |||

|

EMC EN 61000-4-4 Burst |

2 kV with BWK B | |||

|

EMC EN 61000-4-5 Surge |

1 kV / 42 Ω with BWK B | |||

|

EMC EN 61000-4-6 HF line-bound |

10 Veff (150 kHz ... 80 MHz) with BWK A | |||

|

EMC EN 61000-4-8 Magnetic field 50/60 Hz |

100 A/m with BWK A | |||

|

EMC EN 61000-4-9 Magnetic field pulsed |

1000 A/m with BWK A | |||

|

EMC EN 55016-2-1 Interference voltage |

0.15 ... 30 MHz, class A, EN 55022 | |||

|

EMC EN 55016-2-3 Radio interference field strength |

30 ... 1000 MHz, class B, EN 55022 | |||

|

Conformity |

CE according to the EMC directive | |||

|

Further tests |

cULus-listed | |||

| 1) | Thorough bleeding must be ensured |

| 2) | Maximum of 300 bar is admissible |

For applications outside these parameters, please consult us!

|

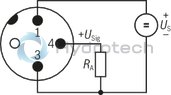

Voltage |

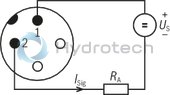

Current (two-wire system) |

Values for US, RA and USig, see Technical data

|

Values for US, RA and USig, see Technical data

|

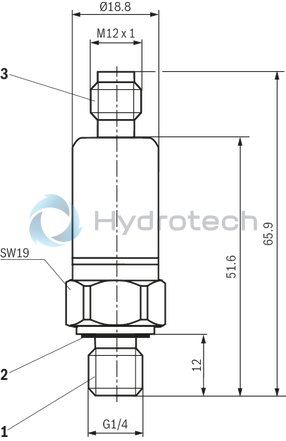

Dimensions in mm

|

1 |

Pressure port G1/4 male thread |

|

2 |

Seal ring |

|

3 |

4-pole M12 connector |

Mating connectors for sensors and valves with connector “K24”, “K35” and “K72”, M12 x 1, with assembled connection line, cable shielded

4P M12 +

Mating connectors for sensors and valves with connector “K24”, “K35” and “K72”, M12 x 1, with assembled connection line, cable shielded

4P M12 +

For sensors and valves with connector “K24”, “K35” and “K72” Cable sets M12, 4-pole, line cross-section 0.34 mm2Data sheet

Spare parts & repair