BOSCH REXROTH

R900762072

$2,988.00 USD

- BOSCH REXROTH

- Material:R900762072

- Model:4WRAE6W30-2X/G24K31/F1V

Quantity in stock: 0

The Bosch Rexroth 4WRAE6W30-2X/G24K31/F1V (R900762072) is a high-performance industrial hydraulic valve designed for reliable control of oil flow direction in accordance with its spool symbol W. This direct-actuated spool valve features integrated electronics for precise actuation and is suitable for subplate mounting with a connection pattern conforming to ISO standards. It comes equipped with concealed manual override and auxiliary actuation for enhanced operational flexibility. The valve operates via proportional solenoids that are centrally threaded and come with detachable coils, allowing for proportional control of the flow based on the electrical input signal. The integrated electronics ensure accurate control without the need for external amplifiers. It is capable of handling a maximum operating pressure of up to bar and can facilitate a maximum flow rate of l/min, making it suitable for various hydraulic applications. Designed with analog connectivity, the valve accepts command values in the mA range and supports a variety of hydraulic fluids including HL, HLP, HLPD, HVLP, HVLPD, HETG, HEES, HEPG, HFDU, and HFDR. The electrical connection utilizes a Connector pole PE according to EN standards and operates at a supply voltage of VDC. The 4WRAE6W30-2X/G24K31/F1V valve's robust construction includes FKM seals to ensure durability and longevity even in demanding conditions. Furthermore, its spring-centered control spool ensures that the system returns to neutral when de-energized. This model's size conforms to CETOP D standards while offering straightforward installation due to its subplate mounting design. Bosch Rexroth's commitment to quality is evident in this component's design which ensures consistent performance for systems requiring precise hydraulic flow direction control without position feedback.

Size 6, symbol W, electrical with integrated electronics, 24 V DC

Industrial hydraulic valve in a high performance range, reliable control of oil flow direction according to hydraulic symbol.

Unpacked Weight: 2.200 kg

The 4/2 and 4/3 proportional directional valves are designed as direct operated devices in plate design. Operation by means of proportional solenoids with central thread and detachable coil. The solenoids are controlled via integrated electronics.

Set-up:

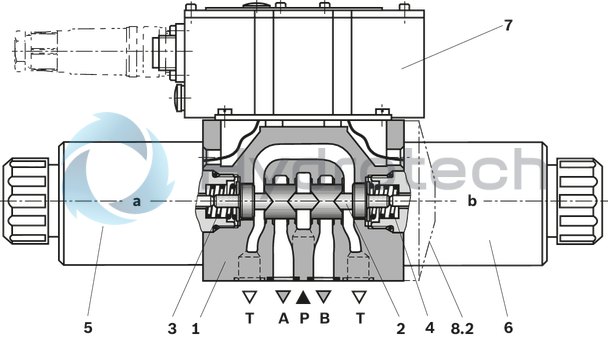

The valve basically consists of:

Housing (1) with connection surface Control spool (2) with compression springs (3 and 4) Solenoids (5 and 6) with central thread Integrated electronics (7)Function:

With de-energized solenoids (5 and 6), central position of the control spool (2) due to compression springs (3 and 4) Direct actuation of the control spool (2) by energization of one proportional solenoid, e. g. energization of solenoid "b" (6) Control spool (2) is moved to the left in proportion to the electrical input signal Connection from P to A and B to T via orifice-type cross-sections with progressive flow characteristics Switching off of the solenoid (6) Control spool (2) is returned to the central position by the compression spring (3)

Valve with two spool positions (type 4WRA...A...):

The function of this valve version basically corresponds to the valve with three spool positions. This 2 spool position valve is, however, only equipped with solenoid “a”. Instead of the 2nd proportional solenoid, there is a plug screw (8.1) with NG 6 or a cover (8.2) with NG10.

Notice:

The tank line must not be allowed to run empty. With corresponding installation conditions, a preload valve (preload pressure approx. 2 bar) must be installed.

| With concealed manual override: With concealed auxiliary actuation |

| Spool valve |

| Direct actuated |

| Maximum flow 75 l/min |

| Size 6, 10 |

| Component series 2X |

| Maximum operating pressure 315 bar |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Spool symbol | Symbol W |

| Max. pressure | 315 |

| Electrical connection description | Connector 7-pole (6 + PE) according to EN 175201-804 |

| Productgroup ID | 9,10,11,12,13,14 |

| Number of ports | 4 |

| Type of actuation | Electrical with integrated electronics |

| Size | 6 |

| Electrical connector | Connector 7-pole (6 + PE) |

| Max. flow | 42 |

| Type of connection | Subplate mounting |

| Connection diagram NFPA | NFPA T3.5.1 R2-2002 D03 |

| Size_CETOP | D03 |

| Nominal flow | 26 |

| Connection diagram | ISO 4401-03-02-0-05 |

| Supply voltage | 24 VDC |

| Number of switching positions | 3 |

| Weight | 2.200 |

| Seals | FKM |

| Connectivity | Analog, command value 4 … 20 mA |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HETG,HEES,HEPG,HFDU,HFDR |

| Hydraulic fluid | HL,HLP,HLPD,HVLP,HVLPD,HETG,HEES,HEPG,HFDU,HFDR |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

|||

|

4 |

WRAE |

‒ |

2X |

/ |

G24 |

/ |

* |

|

01 |

4 main ports |

4 |

|

02 |

Proportional directional valve with integrated electronics |

WRAE |

|

03 |

Size 6 |

6 |

|

Size 10 |

10 |

|

|

04 |

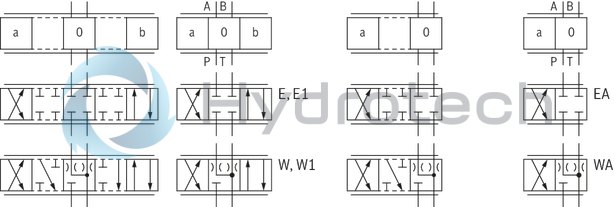

Symbols; for the possible version, see "Symbols/Circuit diagrams" |

E; E1-; W; W1-; EA; WA |

|

Rated flow NG6 |

||

|

05 |

7 l/min |

7 |

|

15 l/min |

15 |

|

|

30 l/min |

30 |

|

|

Rated flow NG10 |

||

|

05 |

30 l/min |

30 |

|

60 l/min |

60 |

|

|

06 |

Component series 20 ... 29 (20 ... 29: unchanged installation and connection dimensions) |

2X |

|

07 |

Supply voltage 24 V |

G24 |

|

Special type of protection |

||

|

08 |

Without special type of protection |

no code |

|

Sea water-resistant |

J 1) |

|

|

Electrical connection |

||

|

09 |

Connector DIN EN 175201-804 |

K31 2) |

|

Electrical interface |

||

|

10 |

Command value ±10 V |

A1 |

|

Command value 4 to 20 mA |

F1 |

|

|

Seal material |

||

|

11 |

NBR seals |

M |

|

FKM seals |

V |

|

|

12 |

Further details in the plain text |

* |

|

1) |

Electrical protection classes on request |

|

|

2) |

Only with NG6: only indicate "K31" for version “J”! |

|

For applications outside these parameters, please consult us!

general

|

Type |

4WRAE | ||

|

Size |

6 | 10 | |

|

Installation position |

any, preferably horizontal | ||

|

Ambient temperature range |

°C |

-20 … +50 | |

|

Storage temperature range |

°C |

-20 … +80 | |

|

Weight |

kg |

2.2 | 6.8 |

hydraulic

|

Size |

6 | 10 | ||

|

Maximum operating pressure |

bar |

315 | ||

|

Maximum operating pressure |

Port P |

bar |

315 | |

|

Port T |

bar |

210 | ||

|

Port A |

bar |

315 | ||

|

Port B |

bar |

315 | ||

|

Maximum flow |

l/min |

42 | 75 | |

|

with double flow |

l/min |

80 | 140 | |

|

Nominal flow |

l/min |

7 15 26 |

30 60 |

|

|

Hydraulic fluid 1) |

Mineral oil (HL, HLP) to DIN 51524 | |||

|

Hydraulic fluid temperature range |

°C |

-20 … +80 | ||

|

preferably |

°C |

+40 … +50 | ||

|

Viscosity range |

mm²/s |

20 … 380 | ||

|

preferably |

mm²/s |

30 … 46 | ||

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 2) |

Class 20/18/15 according to ISO 4406 (c) | |||

|

Hysteresis |

% |

≤ 5 | ||

|

Range of inversion |

% |

≤ 1 | ||

|

Response sensitivity |

% |

≤ 0.5 | ||

| 1) | Additional hydraulic fluids upon request |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

Mineral oils and related hydrocarbons |

HL, HLP |

NBR / FKM |

DIN 51524 |

|

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. |

|||

electrical

|

Size |

6 | 10 | ||

|

Voltage type |

Direct voltage | |||

|

Maximum solenoid current |

A |

2.5 | ||

|

Maximum current consumption |

of the amplifier |

A |

1.8 | |

|

of the amplifier (impulse current) |

A |

3 | ||

|

Solenoid coil resistance |

Cold value at 20 °C |

Ω |

2 | |

|

Maximum hot value |

Ω |

3 | ||

|

Actuated time |

% |

100 | ||

|

Maximum coil temperature 1) |

°C |

+ 150 | ||

|

Power supply |

VDC |

24 | ||

|

Supply voltage range |

V |

19 … 35 | ||

|

Command value input |

"A1" |

V |

± 10 | |

|

Command value input range |

"F1" |

mA |

4 … 20 | |

| 1) | Due to the surface temperatures occurring at the solenoid coils, the European standards ISO 13732-1 and EN 982 need to be adhered to. |

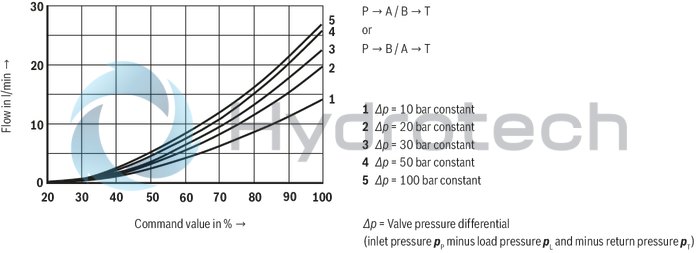

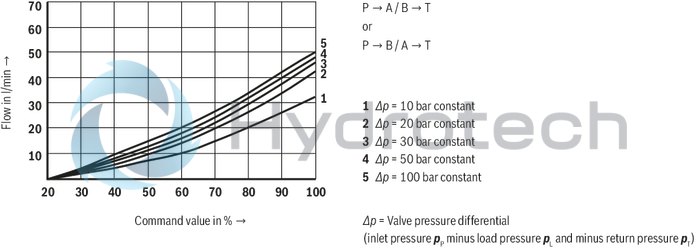

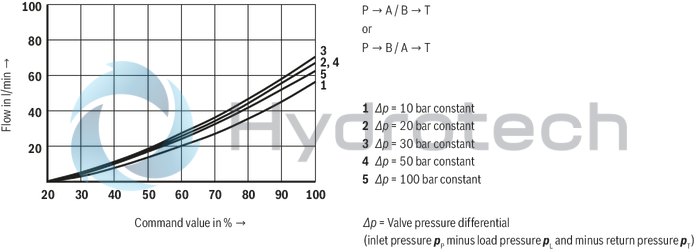

(measured with HLP46, ϑÖl = 40 ±5 °C)

Rated flow 7 l/min at a valve pressure differential of 10 bar

NG6

Rated flow 15 l/min at a valve pressure differential of 10 bar

NG6

Rated flow 30 l/min at a valve pressure differential of 10 bar

NG6

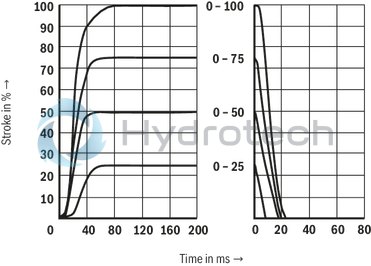

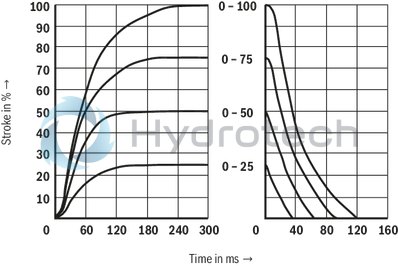

Transition function with stepped electric input signals

NG6

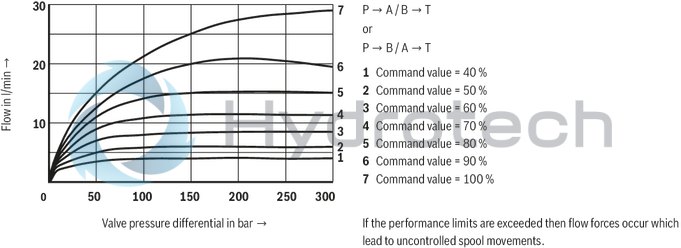

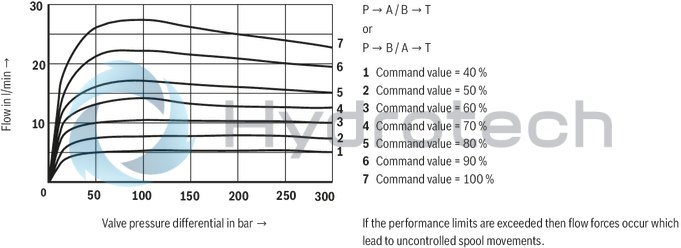

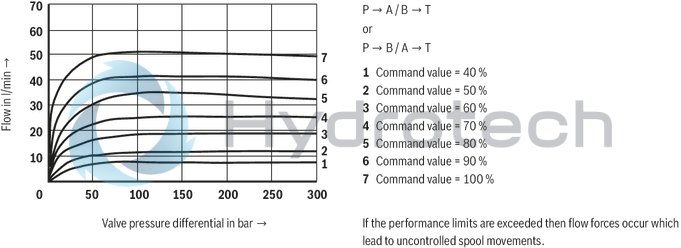

Performance limit rated flow 7 l/min

NG6

Performance limit rated flow 15 l/min

NG6

Performance limit rated flow 30 l/min

NG6

Rated flow 30 l/min at a valve pressure differential of 10 bar

NG10

Rated flow 60 l/min at a valve pressure differential of 10 bar

NG10

Transition function with stepped electric input signals

NG10

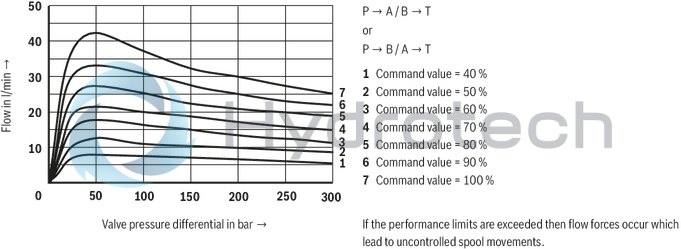

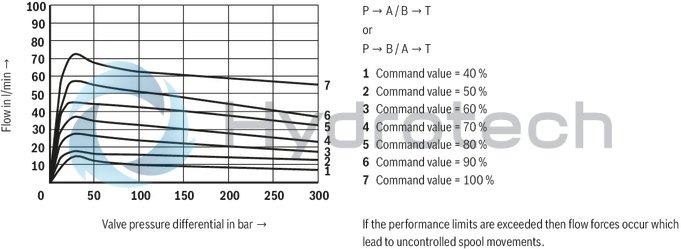

Performance limit rated flow 30 l/min

NG10

Performance limit rated flow 60 l/min

NG10

Symbols

|

With control spool symbol E1- and W1-, the following applies: |

|

|

P → A: qvmax |

B → T: qv/2 |

|

P → B: qv/2 |

A → T: qvmax |

|

Notice: |

|

Type 4WRAE

Type 4WRAE...EA;Type 4WRAE...WA

|

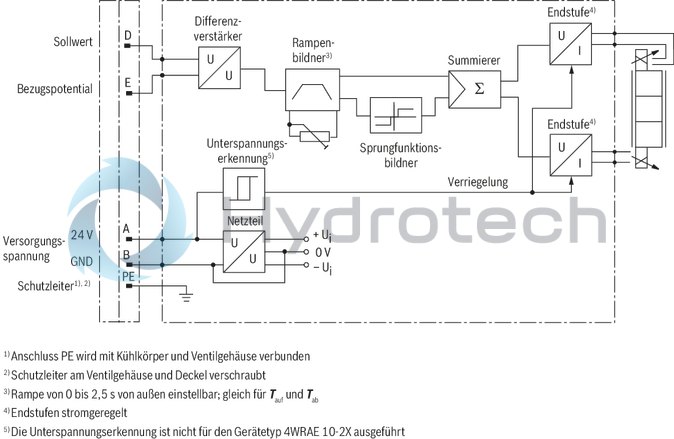

Pin assignment |

Contact |

Signal |

|

Power supply |

A |

24 VDC (19...35 VDC) |

|

B |

GND |

|

|

C |

cannot be used 1) |

|

|

Differential amplifier input (command value) |

D |

Command value (±10 V / 4...20 mA) |

|

E |

Reference potential |

|

|

F |

cannot be used 1) |

|

|

1) |

Contacts C and F must not be connected! |

|

Command value:

Positive command value (0...10 V or 12...20 mA) at D and reference potential at E result in flow from P → A and B → T.

Negative command value (0...-10 V or 12...4 mA) at D and reference potential at E result in flow from P → B and A → T.

With valves with solenoid on side “a” (control spool variant EA and WA), a positive command value at D and reference potential at E (NG6: 4...20 mA and NG10: 12...20 mA) result in flow from P → B and A → T.

Connection cable: Recommendation:

up to 25 m cable length type LiYCY 5 x 0.75 mm²

up to 50 m cable length type LiYCY 5 x 1.0 mm²

External diameter 6.5 … 11 mm

Connect shield on PE only on the supply side

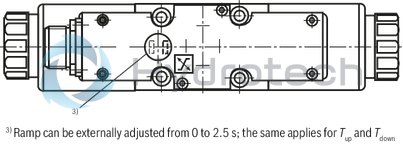

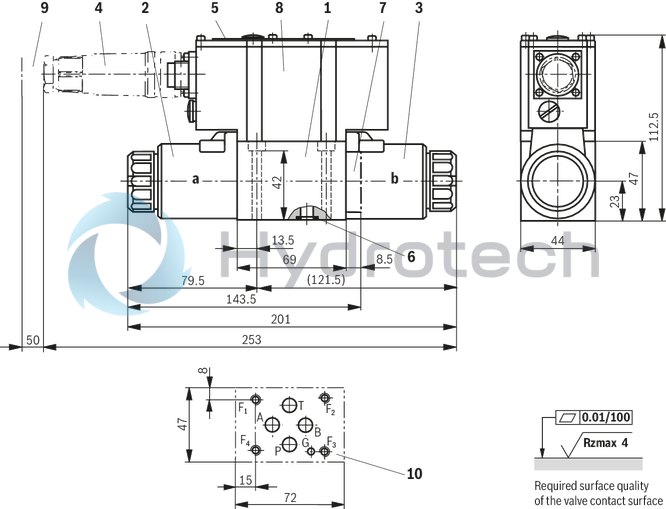

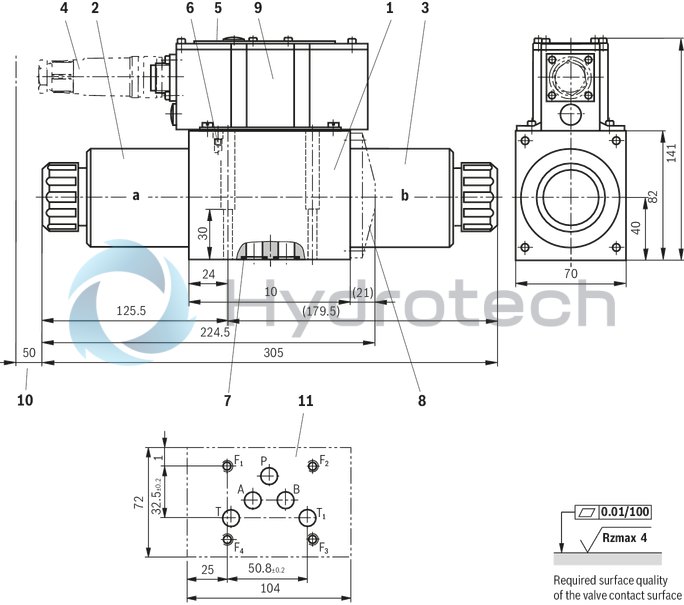

4WRAE 6

Dimensions in mm

|

1 |

Valve housing |

|

2 |

Proportional solenoid "a" |

|

3 |

Proportional solenoid "b" |

|

4 |

Mating connector according to DIN EN 175201-804, separate order |

|

5 |

Name plate |

|

6 |

Identical seal rings for ports A, B, P, and T |

|

7 |

Plug screw for valves with one solenoid (2 spool positions, version "EA" or "WA") |

|

8 |

Integrated electronics (OBE) |

|

9 |

Space required for the connection cable and to remove the mating connector |

|

10 |

Machined valve contact surface; Porting pattern according to ISO 4401-03-02-0-05 (with locating hole) |

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9-flZn-240h-L

tightening torque MA = 7 Nm ± 10%, material no. R913000064 or

4 hexagon socket head cap screws ISO 4762 - M5 x 50 - 10.9

tightening torque MA = 8.9 Nm ± 10%

4WRAE 10

Dimensions in mm

|

1 |

Valve housing |

|

2 |

Proportional solenoid "a" |

|

3 |

Proportional solenoid "b" |

|

4 |

Mating connector according to DIN EN 175201-804, separate order |

|

5 |

Name plate |

|

6 |

Valve bleed screw: Notice: Valves are bled prior to delivery |

|

7 |

Identical seal rings for ports A, B, P and T (T1) |

|

8 |

Cover for valves with one solenoid (2 spool positions, version "EA" or "WA") |

|

9 |

Integrated electronics (OBE) |

|

10 |

Space required for the connection cable and to remove the mating connector |

|

11 |

Machined valve contact surface; Porting pattern according to ISO 4401-05-04-0-05 |

Recommended valve mounting screws (separate order):

4 hexagon socket head cap screws ISO 4762 - M6 x 40 - 10.9-flZn-240h-L

tightening torque MA = 12.5 Nm ± 10 %, material no. R913000058 or

4 hexagon socket head cap screws ISO 4762 - M6 x 40 - 10.9

tightening torque MA = 15.5 Nm ± 10%

Mating connectors for valves with round connector, 6-pole + PE

7P Z31

Mating connectors for valves with round connector, 6-pole + PE

7P Z31

For valves with round connector according to EN 175201-804, 6-pole + PE as well as 6-pole, compatible with VG 95328Data sheet

Spare parts & repair