BOSCH REXROTH

R900702020

$4,989.60 USD

- BOSCH REXROTH

- Material:R900702020

- Model:Z4WEH10E63-4X/6EG24N9ETK4QMAG24/B10

Quantity in stock: 0

The Bosch Rexroth Z4WEH10E63-4X/6EG24N9ETK4QMAG24/B10 (R900702020) is a high-performance directional spool valve designed for electrohydraulic actuation. It functions as a shutoff valve, capable of stopping flow or allowing free flow in both the P and T ports in any spool position. The valve features a porting pattern that adheres to ISO standards, ensuring compatibility with various hydraulic systems. Equipped with wet-pin DC or AC solenoids that can be chosen based on application needs, this valve offers flexibility for different electrical power setups. Additionally, users have the option to include an auxiliary operating device to enhance functionality. For electrical connections, the Z4WEH10E63-4X/6EG24N9ETK4QMAG24/B10 provides options for individual or central connections as detailed in the relevant Rexroth documentation. The valve also offers customizations such as switching time adjustment and stroke setting at the main spool, allowing for precise control over hydraulic operations. For enhanced monitoring and control, it can be equipped with inductive position switches and proximity sensors that operate without contact. This model is part of the X component series from Bosch Rexroth and is built to withstand maximum operating pressures of up to bar levels while facilitating a maximum flow rate measured in liters per minute (l/min). The robust design of this directional spool valve makes it suitable for a variety of demanding applications where precise electrohydraulic control is required.

Size 10, symbol E63, with solenoid actuation, 24 VDC

Industrial hydraulic valve in the medium performance range. Reliable switching of the oil flow direction according to hydraulic symbol

Unpacked Weight: 4.741 kg

|

➀ |

component side |

|

➁ |

plate side |

| Spool valve |

| Pilot-operated |

| Internal pilot oil supply, internal pilot oil return |

| With concealed manual override: With concealed auxiliary actuation |

| Component series 4X |

| Maximum flow 160 l/min |

| Size 10 |

| Maximum operating pressure 315 bar |

| Data Sheet | Download Data Sheet |

| Manual | Download Manual |

| Spool symbol | Symbol E63 |

| Max. pressure | 315 |

| Electrical connection description | Connector 3-pole (2 + PE) according to EN 175301-803 |

| Productgroup ID | 9,10,11,12,13,14 |

| Number of ports | 4 |

| Type of actuation | with solenoid actuation |

| Size | 10 |

| Electrical connector | Connector 3-pole (2 + PE) |

| Max. flow | 160 |

| Type of connection | Sandwich plate |

| Connection diagram NFPA | NFPA T3.5.1 R2-2002 D05 |

| Size_CETOP | D05 |

| Connection diagram | ISO 4401-05-04-0-05 |

| Supply voltage | 24 VDC |

| Number of switching positions | 2 |

| Weight | 4.741 |

| Seals | NBR |

| Hydraulic fluid | HL,HLP,HETG |

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

||

|

Z4 |

WEH |

10 |

– |

4X |

/ |

K4 |

* |

|

01 |

Z4 |

|

|

Type of actuation |

||

|

02 |

electro-hydraulic |

WEH |

|

03 |

Size 10 |

10 |

|

Symbols |

||

|

04 |

see symbols |

|

|

05 |

Component series 40 to 49 (40 to 49: unchanged installation and connection dimensions) |

4X |

|

Pilot control valve |

||

|

06 |

High-power valve (RE 23178) |

6E 1) |

|

07 |

Direct voltage 24 V |

G24 1) |

|

Alternating voltage 230 V, 50/60 Hz |

W230 1) |

|

|

DC voltage 205 V 50/60 Hz |

G205 1;2) |

|

|

For other voltages, frequencies and electric data, see data sheet RE 23178 |

||

|

08 |

Without manual override |

no code |

|

With manual override |

N1) |

|

|

With concealed manual override (standard) |

N9 1) |

|

|

09 |

External pilot oil supply, external pilot oil return |

no code |

|

Internal pilot oil supply, internal pilot oil return (standard) |

ET |

|

|

External pilot oil supply, internal pilot oil return |

T |

|

|

(for type Z4WH... only "no code" available!) |

||

|

10 |

without switching time adjustment |

no code |

|

Switching time adjustment as supply control |

S |

|

|

Switching time adjustment as discharge control |

S2 |

|

|

Electrical connection 1) |

||

|

11 |

Without mating connector, individual connection with connector according to DIN EN 175301-803 |

K43) |

|

For further electrical connections, see RE 23178 |

||

|

Spool position monitoring |

||

|

12 |

Without position switch |

no code |

|

Monitored spool position "a" |

QMAG24 |

|

|

Monitored spool position "b" |

QMBG24 |

|

|

Monitored spool position "a" and "b" |

QMABG24 |

|

|

13 |

No additional details |

Without slash |

|

Additional details |

/ |

|

|

Stroke setting |

||

|

14 |

Without stroke setting |

no code |

|

Stroke setting on side A and B |

10 |

|

|

Stroke setting on side A |

11 |

|

|

Stroke setting on side B |

12 |

|

|

For more information, see stroke setting, mounting options |

||

|

Throttle insert 1) |

||

|

15 |

Without throttle insert |

no code |

|

Throttle Ø 0.8 mm [0.0315 inch] |

B08 |

|

|

Throttle Ø 1.0 mm [0.0394 inch] |

B10 |

|

|

16 |

Without pressure reducing valve |

no code |

|

With pressure reducing valve (use for pilot pressure >250 bar) |

D3 1;4) |

|

|

Seal material |

||

|

17 |

NBR seals |

no code |

|

FKM seals |

V |

|

|

Other seals on request |

||

|

Observe compatibility of seals with hydraulic fluid used. |

||

|

18 |

Further details in the plain text |

* |

| 1) | For connection to the AC voltage mains, a DC solenoid must be used, which is controlled via a rectifier (see table). |

| For individual connection, a mating connector with integrated rectifier can be used (separate order). | |

| 2) | Mating connectors (separate order). |

| 3) | Version "D3" requires installation of a throttle insert "B08" in port P of the pilot control valve! |

|

AC voltage mains (admissible voltage tolerance ± 10%) |

Nominal voltage of the DC solenoid in case of operation with alternating voltage |

Ordering code |

|

110 V - 50/60 Hz 120 V - 60 Hz |

96 V |

G96 |

|

230 V - 50/60 Hz |

205 V |

G205 |

Preferred types and standard units are contained in the EPS (standard price list).

general

|

Size |

10 | ||

|

Weight |

Valve with one solenoid |

kg |

4.2 |

|

Valve with two solenoids |

kg |

4.6 | |

|

Switching time adjustment |

kg |

0.8 | |

|

3-way pressure reducing valve |

kg |

0.4 | |

|

Plate for version "T" |

kg |

0.5 | |

|

Installation position |

any | ||

|

Ambient temperature ranges (NBR seals) |

°C |

-30 … +50 | |

|

Ambient temperature ranges (FKM seals) |

°C |

-20 … +50 | |

hydraulic

|

Size |

10 | |||

|

Maximum operating pressure |

Port P |

External pilot oil supply |

bar |

315 |

|

Internal pilot oil supply (without pressure reducing valve) |

bar |

250 | ||

|

Internal pilot oil supply (with pressure reducing valve) |

bar |

315 | ||

|

Anschluss A |

bar |

315 | ||

|

Port B |

bar |

315 | ||

|

Port T |

with DC solenoid |

bar |

210 | |

|

with AC solenoid |

bar |

160 | ||

|

Maximum flow |

l/min |

160 | ||

|

Minimum pilot pressure |

bar |

12 | ||

|

Pilot volume for switching process |

cm³ |

1.3 | ||

|

Hydraulic fluid 1) |

see table | |||

|

Hydraulic fluid temperature range (NBR seals) |

°C |

-30 … +80 | ||

|

Hydraulic fluid temperature range (FKM seals) |

°C |

-20 … +80 | ||

|

Viscosity range |

mm²/s |

2.8 … 500 | ||

|

Maximum admissible degree of contamination of the hydraulic fluid 2) |

Class 20/18/15 according to ISO 4406 (c) | |||

| 1) | The ignition temperature of the process and operating medium used must be over the maximum solenoid surface temperature. |

| 2) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oil |

HL, HLP |

NBR, FKM |

DIN 51524 |

|

|

Fast bio-degradable hydraulic fluids |

VDMA 24568 |

|||

|

Environmentally compatible |

Insoluble in water |

HETG |

NBR, FKM |

|

|

HEES |

FKM |

|||

|

Soluble in water |

HEPG |

NBR, FKM |

||

|

Other hydraulic fluids on request |

||||

electrical

|

Switching time according to ISO 6403 |

At pilot pressure |

bar |

70 | 140 | 210 | |||

|

Voltage type |

Direct voltage | AC voltage | Direct voltage | AC voltage | Direct voltage | AC voltage | ||

|

On |

ms |

65 | - | 60 | - | 55 | - | |

|

ms |

- | 30 | - | 25 | - | 20 | ||

|

Off |

ms |

- | 30 | - | 30 | - | 30 | |

|

ms |

30 | - | 30 | - | 30 | - | ||

Notices!

Actuation of the manual override is only possible up to a tank pressure of approx. 50 bar. Avoid damage to the bore of the manual override! (Special tool for the operation, separate order, material no. R900024943). When the manual override is blocked, the actuation of the solenoid must be prevented! The simultaneous actuation of the solenoids must be prevented!Inductive position switch type QM: electrical connection

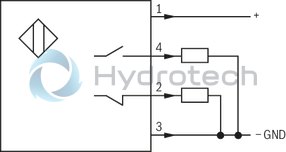

electrical

|

Connection voltage (DC voltage) |

V |

24 | ||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

Switching outputs

|

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout

|

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

For applications outside these parameters, please consult us!

(measured with HLP46, ϑOil = 40 ±5 °C)

Δp-qV characteristic curves

E62

Version "ET"

E62

Version "T"

E63

Version "ET"

E63

Version "T"

E68

Version "ET"

E68

Version "T"

E501)

Version "ET"

| 1) | Opening cross-section in spool position "a" (A2 → B2) = 50 mm2 |

E50

Version "T"

| 1) | Opening cross-section in spool position "a" (A2 → B2) = 50 mm2 |

E51

Version "ET"

E51

Version "T"

E521)

Version "ET"

| 1) | Opening cross-section in spool position "b" (A2 → B2) = 35 mm2 |

E52

Version "T"

| 1) | Opening cross-section in spool position "b" (A2 → B2) = 35 mm2 |

|

➀ |

component side |

|

➁ |

plate side |

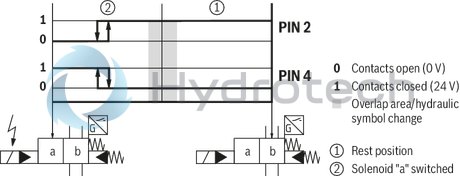

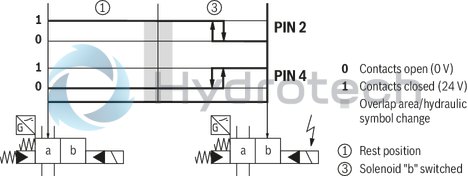

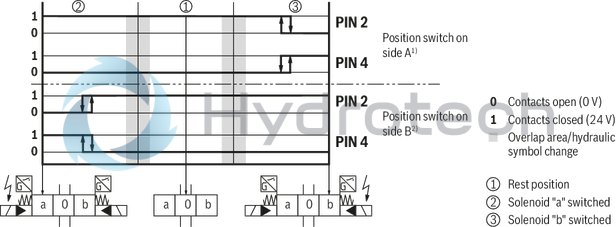

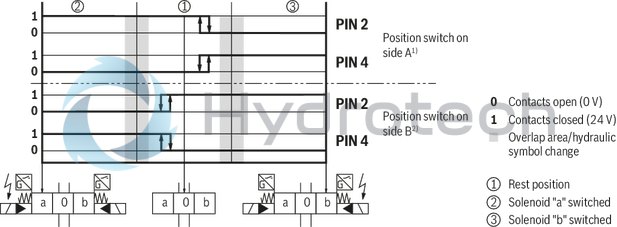

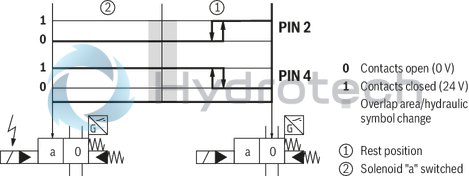

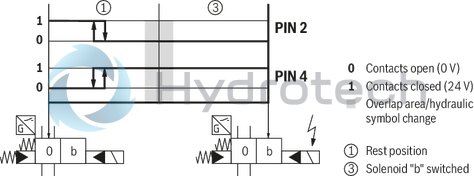

Inductive position switch type QM Switching logics

Version QMA

(Position switch on side B, monitored spool position of the main stage "a")

Version QMA

(Position switch on side B, monitored spool position of the main stage "a")

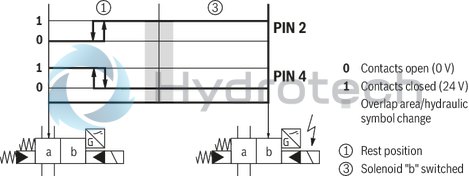

Version QMB

(Position switch on side A, monitored spool position of the main stage "b")

Version QMB

(Position switch on side A, monitored spool position of the main stage "b")

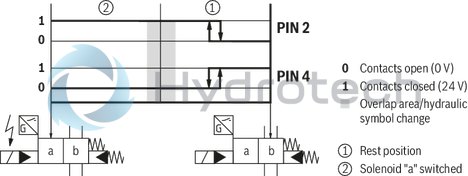

version QMAB

(Position switch on side A and B, monitored spool position "a" and "b")

Version QM0

(Position switch on side A and B, monitored spool position "0")

| 1) No signal change at the position switch on side B with spool position "a" | |

| 2) No signal change at the position switch on side A with spool position "b" |

Version QM0

(Position switch on side B, monitored spool position of the main stage "0")

Version QM0

(Position switch on side A, monitored spool position of the main stage "0")

Dimensions in mm

|

1 |

Name plate complete valve |

|

2 |

Name plate pilot control valve |

|

3 |

Main valve |

|

4 |

Sandwich plate for external pilot control (use for operating pressure > 210 bar) |

|

5 |

Pressure reducing valve "D3" (to be used for pilot pressures above 250 bar)Material no.:NBR seals: R900323180FKM seals: R900323664 |

|

6 |

Space required to remove the mating connector |

|

7 |

Switching time adjustment (throttle check valve); dependent on supply or discharge control installation position (representation: supply control) |

|

8 |

R-ring plate |

|

9 |

Pilot control valve- Type 4WE 6 J.. at symbol E62- Type 4WE 6 Y.. at symbol E50, E51, E52, E63, E68Dimensions () for valve with AC solenoid |

|

10 |

Dimension for valve without manual override |

|

11 |

Dimension for valve with manual override "N";Dimensions () for valve with AC solenoid |

|

12 |

Dimension for valve with concealed manual override "N9"; dimensions () for valve with AC solenoid without manual override |

|

13 |

Solenoid "a" and "b" (rotatable by 90°) |

|

14 |

Identical seal rings for ports A, B, P, TA and TB |

|

15 |

Identical seal rings for ports A, B, P and T |

|

17 |

Valve mounting bores Valve mounting screws (separate order) 4 hexagon socket head cap screws ISO 4762 - M6 - 10.9 |

|

18 |

Valve mounting screws (separate order)4 hexagon socket head cap screws ISO 4762 - M5 - 10.9 |

Notice!

Length and tightening torque of the valve mounting screws must be calculated according to the components mounted.

|

Mounting options |

L1 |

L2 |

|

mm |

mm |

|

| Stroke setting on side A and B | 95 | 149 |

| Stroke setting on side A | 95 | - |

| Stroke setting on side B | - | 149 |

Stroke setting, mounting options

The stroke of the main spool is limited by the stroke setting.

The piston stroke is shortened by untightening the lock nut (17) and clockwise rotation of the adjustment spindle (18). For this, the control chamber has to be depressurized.

Stroke 6 mm (1 rotation = 1 mm stroke)

|

17 |

Lock nut SW27 |

|

18 |

Adjustment spindle, internal hexagon SW5 |

Spool position monitoring

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Dimensions in mm

Inductive position switch type QM

Type Z4WEH 10

Dimensions in mm

|

Mounting options: |

||||

|

Monitored spool position |

Ordering code |

Position switch on side |

||

|

„a“ |

„b“ |

"a" and "b" |

||

|

„a“ |

QMAG24 |

X |

||

|

„b“ |

QMBG24 |

X |

||

|

"a" and "b" |

QMABG24 |

X |

||

Stroke setting, mounting options

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair