BOSCH REXROTH

SLIDING PLATE

3842541566

$38.44 USD

- BOSCH REXROTH

- Material:3842541566

- Model:SLIDING PLATE VF65 PE

Quantity in stock: 16

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Bosch Rexroth directly.***

The Bosch Rexroth SLIDING PLATE (3842541566) is a versatile component designed for use in conveyor systems where the transport of products with irregular shapes or those unsuitable for accumulation is required. This PE wear pad VFplus is engineered to facilitate a smooth and stable movement of workpiece pallets across the conveyor, ensuring efficient handling of materials. The product features a level WT surface without indentations, allowing the entire top area to be utilized for building upon, with all other components pre-mounted below the surface for convenience. The SLIDING PLATE is compatible with Bosch Rexroth's ID identification system and allows for the integration of mobile data tags, enhancing trackability and process control within manufacturing operations. It has been designed to accommodate workpiece pallets that may extend beyond the WT, provided that their center of gravity is taken into account. Customers are required to equip their workpiece pallets with wear pads, which can be made from steel for harsh environments or PE for cleaner settings. The modular concept of this product supports various lengths of workpiece pallets up to a specified maximum, ensuring adaptability across different applications. Additionally, it includes centering bushings for accurate positioning within positioning units. The SLIDING PLATE itself is constructed from anodized aluminum for durability and corrosion resistance, while end pieces are made from black PA. The wear pads available are either stainless steel with a high hardness rating or PE depending on operational requirements. This component ensures maximum transport speed efficiency and supports varying sizes and weights of workpiece pallets, making it an essential part of any conveyor system designed by Bosch Rexroth.

The Bosch Rexroth SLIDING PLATE (3842541566) is a versatile component designed for use in conveyor systems where the transport of products with irregular shapes or those unsuitable for accumulation is required. This PE wear pad VFplus is engineered to facilitate a smooth and stable movement of workpiece pallets across the conveyor, ensuring efficient handling of materials. The product features a level WT surface without indentations, allowing the entire top area to be utilized for building upon, with all other components pre-mounted below the surface for convenience. The SLIDING PLATE is compatible with Bosch Rexroth's ID identification system and allows for the integration of mobile data tags, enhancing trackability and process control within manufacturing operations. It has been designed to accommodate workpiece pallets that may extend beyond the WT, provided that their center of gravity is taken into account. Customers are required to equip their workpiece pallets with wear pads, which can be made from steel for harsh environments or PE for cleaner settings. The modular concept of this product supports various lengths of workpiece pallets up to a specified maximum, ensuring adaptability across different applications. Additionally, it includes centering bushings for accurate positioning within positioning units. The SLIDING PLATE itself is constructed from anodized aluminum for durability and corrosion resistance, while end pieces are made from black PA. The wear pads available are either stainless steel with a high hardness rating or PE depending on operational requirements. This component ensures maximum transport speed efficiency and supports varying sizes and weights of workpiece pallets, making it an essential part of any conveyor system designed by Bosch Rexroth.

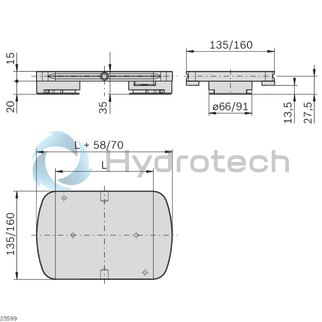

PE wear pad VFplus 65

Unpacked Weight: 0.015 kg

For transporting products that are not suitable for accumulation operation or are unstable due to their geometry

Max. transport speed for operation with workpiece pallets: vN = 18 m/min Workpiece pallet wear pads either made of: Steel, for use in harsh environments PE, for use in clean environments Workpiece pallet load (workpiece, support, etc.) Size 65: 8 kg Size 90: 8 kg The modular concept allows for workpiece pallet lengths of up to 500 mm*. With centering bushings for positioning in the positioning unit.* For workpiece pallet with L > 300 mm, combine two 90° curve wheels with intermediate section (min. 200 mm).

For workpiece pallet with L < 300 mm, use 180° curve wheel

Minimum length of the workpiece pallets: Size 65: Lmin = 76 mm Size 90: Lmin = 114 mm Minimum length of the workpiece pallets in order to incorporate the positioning unit: Size 65: Lmin = 125 mm Size 90: Lmin = 125 mm Minimum length WT for passive bridge: L ≥ 300 mm

Material:

WT plate: aluminum; natural, anodized End pieces: PA; black Workpiece pallet wear pads: steel; stainless, HV ≥ 480 or PEScrew

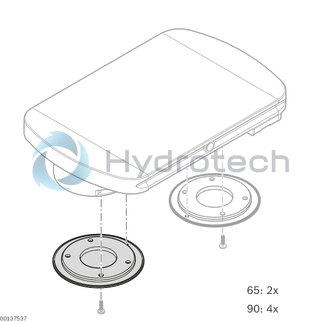

PE wear pad

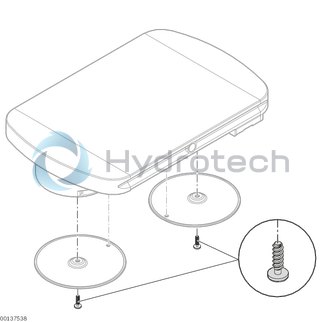

Steel wear pad

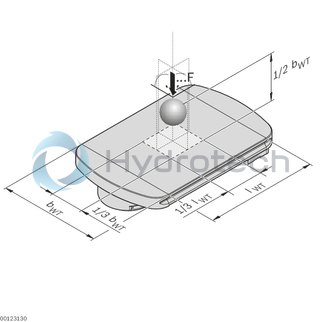

| Level WT surface with no indentations |

| The entire top of the WT can be built upon since everything else on the section is ready-mounted below the top of the WT. |

| Compatible with the ID 15 identification system. The integrated installation of a mobile data tag is also possible |

| The product may also protrude beyond the WT if the position of the center of gravity is taken into consideration |

| The mounted workpiece pallet must be provided with wear pads (steel or PE) by the customer. |

| 1: WT plate |

| 2: Centering bushing |

| 3: End pieces |

| 4: Steel workpiece pallet wear pad |

| 5: PE workpiece pallet wear pad |

| Data Sheet | Download Data Sheet |

| 3D CAD | Download 3D CAD |

| Productgroup ID | 2 |

| Packaging unit | 10 |

| Material | PE |

| Weight | 0.015 |

| Required accessories | Screw 3842543246 (not in scope of delivery) |

| Size [b] | 65 |

VarioFlow workpiece pallet (WT)

Optimum center of gravity range for smooth operation

Workpiece pallet VFplus 65, VFplus 90