BOSCH REXROTH

R170225020

$469.47 USD

- BOSCH REXROTH

- Material:R170225020

- Model:LSAHE-H-50-DD

Quantity in stock: 0

The Bosch Rexroth LINEAR-SET LSAHE-H-50-DD (R170225020) is a high-precision linear motion system designed for heavy-duty applications that require reliable and precise linear movement. This linear set is crafted from aluminum, providing a robust yet lightweight solution for various linear motion needs. The set includes an aluminum precision housing that incorporates a super linear bushing H, known for its ability to compensate for misalignments of up to 0.3 feet, ensuring smooth and accurate operation even in demanding conditions. Equipped with integrated wiper seals on both sides, the LINEAR-SET LSAHE-H-50-DD ensures protection against contaminants, thereby extending the life of the system and reducing maintenance needs. These wiper seals also contribute to the frictional drags generated by the bushings when not under radial load, which are dependent on speed and lubrication conditions. The system's shaft diameter 'd' is specifically designed to work seamlessly with the included super LB H bushing, which can be secured firmly with bolts and offers relubrication capabilities for long-term performance. The outer diameter 'D' is tailored to fit standard applications while allowing maximum permissible linear speeds (vmax) and accommodating dynamic load capacities that vary based on size specifications provided. This linear guide type caters to a wide temperature range from -20°C to +80°C, making it suitable for different working environments. It has been engineered to handle maximum accelerations (amax), static load ratings (C), and breakaway forces efficiently. The radial clearance comes pre-clamped to the h6 shaft lower limit and set to zero-clearance, ensuring optimal performance from installation. Overall, this Bosch Rexroth product belongs to a sophisticated product group known for its durability, precision engineering, and adaptability in various industrial applications where accurate linear motion is critical. With its adjustable features and heavy-duty design, it meets the stringent requirements of users seeking top-tier components for their machinery or systems.

Linear set (aluminum), HE-H-50, with two seals

Linear set (aluminum)

Heavy-duty, adjustable

With super LB H

Shaft diameter d = 50

With two seals

Version: Standard

Unpacked Weight: 2.698 kg

| Precision housing (aluminum) |

| super linear bushing H |

| Compensate for misalignments of up to 30 ft |

| Integrated wiper seals |

| Secured with bolt |

| Relubricatable |

| Data Sheet | Download Data Sheet |

| 2D CAD | Download 2D CAD |

| 2D CAD | Download 2D CAD |

| 3D CAD | Download 3D CAD |

| 3D CAD | Download 3D CAD |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Manual | Download Manual |

| Size V | 12 |

| Series | Super H |

| Footnote friction force FR | Frictional drags generated by linear bushings with integrated wiper seals on two sides when not under radial load. The frictional drags depend on speed and lubrication. |

| Size E1 | 108 |

| Footnote dynamic load capacity C | The load capacities apply for the main direction of loading. |

| Size H | 50 |

| Max. acceleration amax | 150 |

| Permissible ambient temperature | -20 °C ... +80 °C |

| Outer diameter D | 75 |

| Breakaway force | 15 |

| Size H4 | 37 |

| Maximum permissible linear speed vmax | 5 |

| Size D | 75 |

| Footnote static load capacity C0 | The load capacities apply for the main direction of loading. |

| Size N1 | 49 |

| Static load rating C0 | 12200 |

| Size M | 66 |

| Friction force | 6 |

| Size A | 132 |

| Radial clearance | Comes clamped to h5 shaft (lower limit) and set to zero-clearance |

| Productgroup ID | 17 |

| Size N2 | 34 |

| Size E3 | 108 |

| Permissible ambient temperature (max) | |

| Size E2 | 50 |

| Size E4 | 85 |

| Size SW | 8 |

| Permissible ambient temperature (min) | |

| Size S | 13.5 |

| Shaft diameter d | 50 |

| Linear guide type | Linear bushing and shaft |

| Filter for linear bushings and shafts | Linear sets with linear bushings |

| Format of linear bushings | HE – Heavy-duty, adjustable |

| Dynamic load capacity C | 16000 |

| Size L | 101 |

| Size S2 | 10 |

| Weight | 2.698 |

| Size D1 with tolerance | |

| Size H1 | 105 |

General technical data

|

Ø d |

mm |

20 | 25 | 30 | 40 | 50 | 60 |

|

amax |

m/s² |

150 | |||||

|

vmax |

m/s |

5 | |||||

|

m |

kg |

0.29 | 0.58 | 0.88 | 1.63 | 2.7 | 5.2 |

|

FR 1) |

N |

2.5 | 3 | 4 | 5 | 6 | 7 |

|

Breakaway force |

N |

5 | 7 | 9 | 12 | 15 | 18 |

|

Radial clearance |

Comes clamped to h5 shaft (lower limit) and set to zero clearance | ||||||

|

Operating conditions |

|||||||

|

Permissible ambient temperature (min ... max) |

-20 °C ... +80 °C | ||||||

| 1) | Frictional drags generated by Linear Bushings with integrated wiper seals on two sides when not under radial load. The frictional drags depend on speed and lubrication. |

Load capacities and load moments

|

Ød |

mm |

20 | 25 | 30 | 40 | 50 | 60 |

|

C 1) |

N |

2520 | 4430 | 6300 | 9680 | 16000 | 23500 |

|

C0 1) |

N |

1880 | 3360 | 5230 | 7600 | 12200 | 18700 |

| 1) | The load ratings apply for the main direction of loading. |

| The load ratings are based on a total travel of 100, 00 m. When based on 50 000 m, the values in the table need to be multiplied by 1.26. |

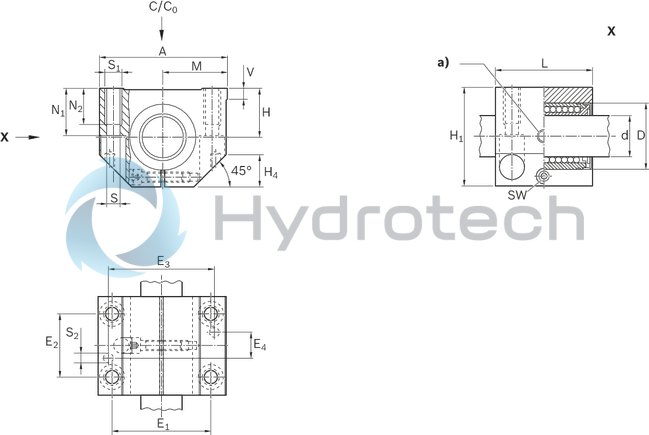

Legend

|

Symbol |

Description |

Unit |

|

Ød |

Shaft diameters |

mm |

|

amax |

Maximum acceleration travel |

m/s2 |

|

C |

Dynamic load capacity |

N |

|

C0 |

Static load capacity |

N |

|

FR |

Friction force |

N |

|

m |

Mass |

kg |

|

vmax |

Maximum permissible speed |

m/s |

See "Technical data – Load direction factors" and the diagrams/characteristic curves section for exact values for the 4 main directions of loading.

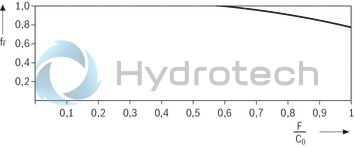

Effect of load direction on load rating

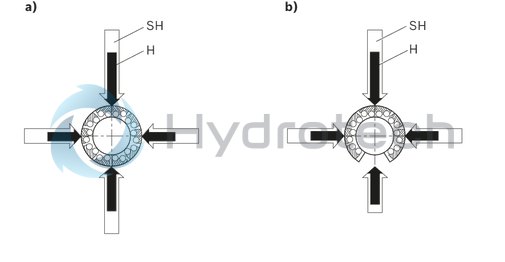

| a) | Closed |

| b) | Open |

Main direction of loading

Load direction factors

The load ratings C and C0 apply for the load direction ρ = 0°. For all other load directions, the load ratings must be multiplied by the factors fr (dynamic load rating C) or fρ0 (static load rating C0).

Load direction factor Super H

|

Shaft |

Load direction factor (dynamic load capacity) |

|||||

|

Ø d (mm) |

⇩ |

⇒⇐ |

⇑ |

⇩ |

⇒⇐ |

⇑ |

|

20 - 25 |

1 |

0,80 |

0,98 |

1 |

0,80 |

0,67 |

|

30 - 60 |

1 |

0,70 |

0,91 |

1 |

0,70 |

0,62 |

|

Load direction factor (static load capacity) |

||||||

|

20 - 25 |

1 |

0,70 |

0,87 |

1 |

0,70 |

0,67 |

|

30 - 60 |

1 |

0,62 |

0,80 |

1 |

0,62 |

0,61 |

|

|

|||||

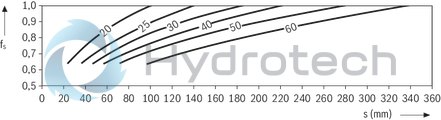

Reduced load capacity with short stroke

In case of short stroke, the service life of the shaft is less than that of the super Linear Bushing. The load ratings C specified in the tables must therefore be multiplied by the factor f.s .

| 1) | fs = factor |

| 2) | s = movement path |

Reduced load capacity with high load

The load rating is reduced under high load F. The dynamic load rating must be multiplied by the load factor f.F .

| 1) | fF = load factor |

Definition of dynamic load ratings

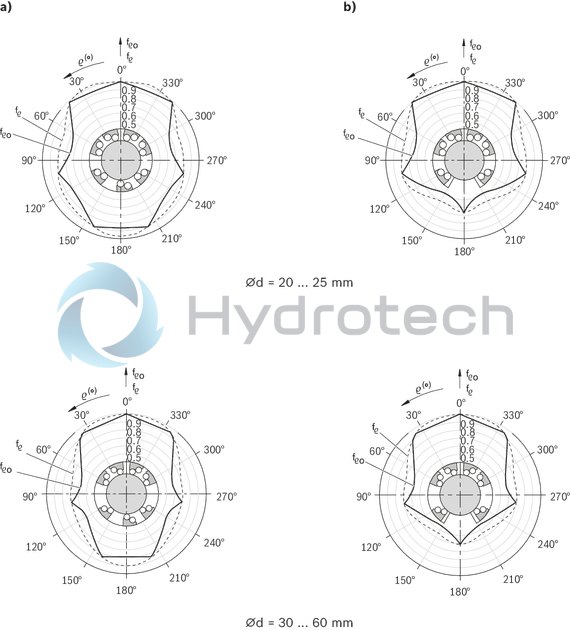

Load direction factors

| a) | Closed |

| b) | Open |

Super Linear Bushings can be installed in any location. Choose a location that ensures that the main direction of loading is always ρ = 0°.

| a) | Lubricating hole sealed with plastic cap |

| M8x1 (Ø d 20 – 50 mm) | |

| M10x1 (Ø d = 60 mm) |

Dimensions

|

Ød |

mm |

20 | 25 | 30 | 40 | 50 | 60 |

|

D |

mm |

32 | 40 | 47 | 62 | 75 | 90 |

|

A |

mm |

60 | 78 | 87 | 108 | 132 | 164 |

|

E1 |

45 mm ±0.15 | 60 mm ±0.15 | 68 mm ±0.15 | 86 mm ±0.15 | 108 mm ±0.2 | 132 mm ±0.2 | |

|

E2 |

32 mm ±0.15 | 40 mm ±0.15 | 45 mm ±0.15 | 58 mm ±0.15 | 50 mm ±0.2 | 65 mm ±0.2 | |

|

E3 |

mm |

50 | 64 | 72 | 90 | 108 | 132 |

|

E4 |

mm |

15 | 17 | 20 | 25 | 85 | 108 |

|

H |

mm |

25 | 30 | 35 | 45 | 50 | 60 |

|

Tolerance for H 1) |

µm |

+ 8 - 16 |

- - |

+ 8 - 16 |

|||

|

H1 |

mm |

50 | 60 | 70 | 90 | 105 | 125 |

|

H4 |

mm |

16 | 20 | 22 | 28 | 37 | 45 |

|

L |

mm |

46 | 59 | 69 | 81 | 101 | 126 |

|

M 1) |

30 mm ±0.01 | 39 mm ±0.01 | 43.5 mm ±0.01 | 54 mm ±0.01 | 66 mm ±0.01 | 82 mm ±0.01 | |

|

N1 |

mm |

24 | 29 | 34 | 44 | 49 | 59 |

|

N2 |

mm |

18 | 22 | 26 | 34 | 42 | |

|

S |

mm |

6.6 | 8.4 | 10.5 | 13.5 | 17.5 | |

|

S1 |

M8 | M10 | M12 | M16 | M20 | ||

|

S2 |

mm |

5 | 6 | 8 | 10 | 12 | |

|

SW |

mm |

4 | 5 | 6 | 8 | 10 | |

|

V |

mm |

5 | 6.5 | 8 | 10 | 12 | 13 |

| 1) | Clamped (fastened) in relation to Ø d. |

| a) | Lubricating hole sealed with plastic cap |

| M8x1 (Ø d 20 – 50 mm) | |

| M10x1 (Ø d = 60 mm) |

Legend

|

Symbol |

Description |

Unit |

|

Ød |

Shaft diameters |

mm |

|

C/C0 |

Main direction of loading |

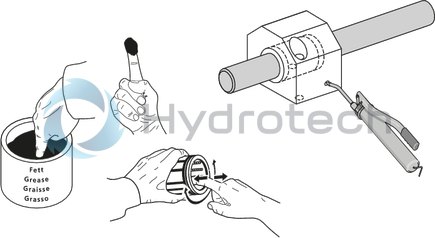

Linear Sets with Super H Linear Bushings do not come with initial lubrication. Grease the Linear Bushings before use. Service life data is based on initial lubrication and relubricated Linear Bushings.

Hydraulic-type lube nipple according to DIN 71412 Form A

Hydraulic-type lube nipple according to DIN 71412 Form A

Catalog

Instructions

Service

Funnel-type lube nipple according to DIN 3405 Form A

Funnel-type lube nipple according to DIN 3405 Form A

Catalog

Instructions

Service

Hollow screw

Hollow screw

For relubricating and securing Super Linear Bushing H (closed) via locating hole S.1Catalog

Instructions

Service

Locating screws for super linear bushings H and SH

Locating screws for super linear bushings H and SH

For securing Super Linear Bushing H and SHCatalog

Instructions

Service