SUN HYDRAULICS

XPJ

$107.60 USD

Tags:

- SUN HYDRAULICS

- Material:XPJ

- Summary:Manifold

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

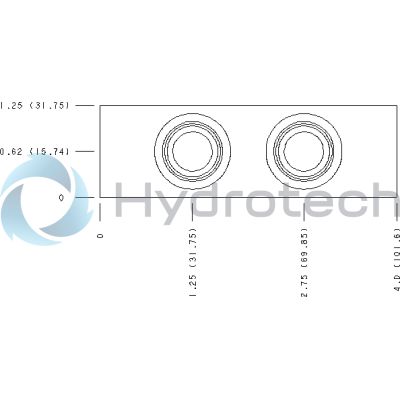

The Sun Hydraulics XPJ (Material Number: XPJ) is a line mount manifold designed for hydraulic systems requiring cross pilot configurations with a common port 4s. This manifold features two open cavities and is compatible with the T-21A cavity type. It supports SAE 8 port sizes, making it suitable for various hydraulic applications where precise control and reliability are essential. The XPJ manifold has a mounting hole diameter of 0.34 inches (8.6 mm) and is designed for through-hole mounting, accommodating two mounting holes to ensure secure installation. Constructed from 6061T651 aluminum, this manifold offers excellent corrosion resistance, which is crucial in demanding environments. Despite not being anodized, the material choice provides sufficient protection against corrosion while maintaining cost-effectiveness and structural integrity under pressure conditions up to 3000 psi (210 bar). This product is ideal for integrating into hydraulic systems that require robust performance without compromising on durability or efficiency.

The Sun Hydraulics XPJ (Material Number: XPJ) is a line mount manifold designed for hydraulic systems requiring cross pilot configurations with a common port 4s. This manifold features two open cavities and is compatible with the T-21A cavity type. It supports SAE 8 port sizes, making it suitable for various hydraulic applications where precise control and reliability are essential. The XPJ manifold has a mounting hole diameter of 0.34 inches (8.6 mm) and is designed for through-hole mounting, accommodating two mounting holes to ensure secure installation. Constructed from 6061T651 aluminum, this manifold offers excellent corrosion resistance, which is crucial in demanding environments. Despite not being anodized, the material choice provides sufficient protection against corrosion while maintaining cost-effectiveness and structural integrity under pressure conditions up to 3000 psi (210 bar). This product is ideal for integrating into hydraulic systems that require robust performance without compromising on durability or efficiency.

| Body Type | Line mountLine mount |

| Interface | NoneNone |

| Body Features | Cross pilot with common port 4sCross pilot with common port 4s |

| Mounting Hole Diameter | .34 in.8.6 mm |

| Mounting Hole Depth | ThroughThrough |

| Mounting Hole Quantity | 22 |

| Open Cavities | 22 |

| Cavity | T-21A |

| Port Size | SAE 8SAE 8 |

Show FAQ

Additional Resources

- Standard Line Mount Manifolds for High Flow Valves

- QuickDesign with SmartConnect Offers Drag-and-Drop Schematic Tool

- Manufacturing Sun Cartridge Cavities

- Sun Model Code Explanation; 999-901-334

- Custom Integrated Packages from Sun

- Fluid and Temperature Recommendations

- QuickDesign & SunDesign: Sun's 3- & 5-Axis Solutions

- Manifolds: Materials of Construction

- Sun's Floating Style Screw-In Cartridge

Notes:

- Important: Carefully consider the maximum system pressure. The pressure rating of the manifold is dependent on the manifold material, with the port type/size a secondary consideration. Manifolds constructed of aluminum are not rated for pressures higher than 3000 psi (210 bar), regardless of the port type/size specified.