SUN HYDRAULICS

RVETLCN

$195.70 USD

Tags:

- SUN HYDRAULICS

- Material:RVETLCN

- Model:RVET-LCN

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics RVETLCN (RVETLCN) is a ventable, pilot-operated anti-shock relief cartridge designed to limit maximum system pressure and control the rate of pressure rise. This valve features a unique mechanism where it opens and then ramps closed at a constant speed, independent of settings and flows. It includes three ports, with a vent port that allows for remote control via other pilot or 2-way valves. The valve\u2019s adjust screw determines both the maximum relief setting and the minimum threshold setting. Thanks to its internal modulating design, it effectively reduces issues associated with cavitation, like noise and manifold erosion. This valve is capable of accepting maximum pressure at port 2, making it suitable for cross-port relief circuits but not for load-holding applications. When inlet port 1 exceeds the threshold pressure, the valve opens to tank port 2, allowing the pilot section to move forward at a steady rate until it reaches a mechanical stop for maximum setting. It provides protection for hydrostatic drives by mitigating jerks from sudden reversals and can be used with switching devices to emulate ramp characteristics typical of proportional valves. The RVETLCN supports small power units by starting them against an anti-shock relief to extend pump life. Back pressure on tank port 2 directly adds to the valve setting at a 1:1 ratio. The main stage orifice is designed to resist contamination, incorporating Sun's floating style construction that minimizes internal binding due to excessive torque or machining variations. With a capacity of 30 gpm (120 L/min) and maximum operating pressure of 5000 psi (350 bar), this cartridge offers reliable performance in demanding hydraulic systems.

The Sun Hydraulics RVETLCN (RVETLCN) is a ventable, pilot-operated anti-shock relief cartridge designed to limit maximum system pressure and control the rate of pressure rise. This valve features a unique mechanism where it opens and then ramps closed at a constant speed, independent of settings and flows. It includes three ports, with a vent port that allows for remote control via other pilot or 2-way valves. The valve\u2019s adjust screw determines both the maximum relief setting and the minimum threshold setting. Thanks to its internal modulating design, it effectively reduces issues associated with cavitation, like noise and manifold erosion. This valve is capable of accepting maximum pressure at port 2, making it suitable for cross-port relief circuits but not for load-holding applications. When inlet port 1 exceeds the threshold pressure, the valve opens to tank port 2, allowing the pilot section to move forward at a steady rate until it reaches a mechanical stop for maximum setting. It provides protection for hydrostatic drives by mitigating jerks from sudden reversals and can be used with switching devices to emulate ramp characteristics typical of proportional valves. The RVETLCN supports small power units by starting them against an anti-shock relief to extend pump life. Back pressure on tank port 2 directly adds to the valve setting at a 1:1 ratio. The main stage orifice is designed to resist contamination, incorporating Sun's floating style construction that minimizes internal binding due to excessive torque or machining variations. With a capacity of 30 gpm (120 L/min) and maximum operating pressure of 5000 psi (350 bar), this cartridge offers reliable performance in demanding hydraulic systems.

Ventable, pilot-operated, anti shock relief cartridges limit maximum system pressure and also limit the rate of pressure rise. The valve opens and then ramps closed at a constant speed, independent of settings and flows. These 3 port valves include a vent port (port 3) that connects between the main piston and the pilot stage to provide for remote control by other pilot or 2-way valves. The adjust screw determines the maximum (relief) setting and the minimum (threshold) setting.

- Because the modulating occurs inside the cartridge, these valves are immune to most of the problems associated with cavitation, namely noise and manifold erosion.

- Will accept maximum pressure at port 2; suitable for use in cross port relief circuits.

- A remote pilot relief on port 3 (vent) will control the valve below its own setting.

- Not suitable for use in load holding applications.

- When pressure at the inlet (port 1) exceeds the threshold setting, the valve opens to tank (port 2). The pilot section moves forward at a steady rate, increasing the setting by compressing the pilot spring. Maximum setting is achieved when the pilot section reaches a mechanical stop.

- Valve provides protection for hydrostatic drives by reducing the jerk caused by sudden reversals. The valve is suitable for cross-port applications.

- When used with a switching device, the valve can provide the ramp characteristic typically provided by proportional valves.

- Small power units can be started against an anti shock relief to provide longer pump life.

- Back pressure on the tank port (port 2) is directly additive to the valve setting at a 1:1 ratio.

- The main stage orifice is protected against contamination.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

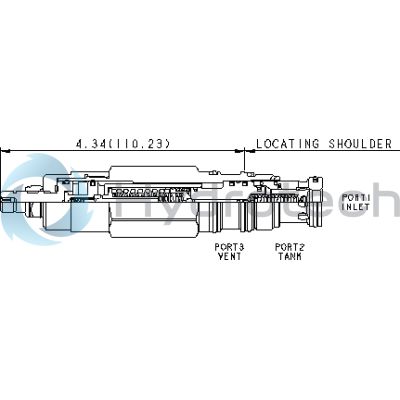

| Cavity | T-2A |

| Series | 2 |

| Capacity | 30 gpm120 L/min. |

| Factory Pressure Settings Established at | 4 gpm15 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Control Pilot Flow | 10 - 25 in³/min.0,16 - 0,41 L/min. |

| Response Time - Typical | 2 ms2 ms |

| U.S. Patent # | 6,039,0706,039,070 |

| Pressure Ramp Up Time | 200 - 400 ms200 - 400 ms |

| Adjustment - Number of Clockwise Turns to Increase Setting | 4.54.5 |

| Valve Hex Size | 1 1/8 in.28,6 mm |

| Valve Installation Torque | 45 - 50 lbf ft61 - 68 Nm |

| Adjustment Screw Internal Hex Size | 5/32 in.4 mm |

| Locknut Hex Size | 9/16 in.15 mm |

| Locknut Torque | 80 - 90 lbf in.9 - 10 Nm |

| Seal kit - Cartridge | Viton: 990-402-006 |

Show FAQ

Additional Resources

- Tri-Grip Handknob Now Offered From Sun as a Standard Control Option

- QuickDesign with SmartConnect Offers Drag-and-Drop Schematic Tool

- Sun Introduces 'Hybrid' Valves

- CE/TÜV Certified Pressure Relief Valves

- Pressure Relief and Regulating Cartridge Valve Technical Tips

- Pilot Operated, Balanced Poppet Relief Valves

- Sun Expands Corrosion-Resistant Solutions

- Sun Offers Zinc-Nickel Plating for Corrosion Resistance

- Sun Cartridges with EPDM Seals

- Series 4 PLUS Cartridges Offer Higher Flows with Lower Pressure Losses

- Pilot-Operated, Balanced Poppet, Anti Shock Reliefs

- CavitySaver multi-function valves deliver single-cartridge solutions

- 'Soft' Relief Eliminates Pressure Spikes

- Manufacturing Sun Cartridge Cavities

- Pressure Relief and Regulating Valves

- Cavity Information (S-171) and Tooling

- Sun Model Code Explanation; 999-901-334

- Cartridges: Materials of Construction

- Fluid and Temperature Recommendations

- Performance Data

- Sun's Floating Style Screw-In Cartridge

- Units of Measure, Settings, and Conversions

Notes:

- Patents are pending for this product.