SUN HYDRAULICS

FSCDXAN

$107.60 USD

Tags:

- SUN HYDRAULICS

- Material:FSCDXAN

- Model:FSCD-XAN

- Summary:Cartridge

Quantity in stock: 3

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics FSCDXAN (Material Number: FSCDXAN) is a precision-engineered flow divider designed to split hydraulic oil flow into two separate branches within a circuit at a specified ratio. This sliding-spool, pressure-compensated device is ideal for applications involving unidirectional hydraulic motors, hydraulic cylinders requiring one-way flow division, and multiple circuits powered by a single pump supply. The FSCDXAN ensures the leg of the circuit with the highest load receives a greater percentage of the flow during dividing mode. It should be noted that this valve functions strictly as a divider; reverse flow through the valve is not recommended. The FSCDXAN features interchangeable cartridges with consistent flow paths and cavity dimensions for a given frame size, allowing for versatile application across various systems. The operational accuracy of this valve is contingent upon proper design considerations to accommodate inherent inaccuracies, especially in systems with rigid mechanical connections between actuators or motors. Such configurations may experience cavitation or lockup due to variations in speed and load distribution. Key specifications include a cavity size of T-31A, series 1 classification, and capacity ranging from 1.5 to 8 gpm (6 to 30 L/min). It operates efficiently at pressures up to 5000 psi (350 bar) with divisional accuracy rates of 6.5% at minimum input flow and 3.5% at maximum input flow. The pressure drop varies from 30 psi (2 bar) at minimum rated input flow to 250 psi (18 bar) at maximum rated input flow. The valve\u2019s hex size measures .78 inches (22.2 mm), and it requires an installation torque between 30-35 lbf ft (41-47 Nm). The model weighs approximately .60 lbs (.30 kg) and utilizes Viton seal kits for optimal performance and durability.

The Sun Hydraulics FSCDXAN (Material Number: FSCDXAN) is a precision-engineered flow divider designed to split hydraulic oil flow into two separate branches within a circuit at a specified ratio. This sliding-spool, pressure-compensated device is ideal for applications involving unidirectional hydraulic motors, hydraulic cylinders requiring one-way flow division, and multiple circuits powered by a single pump supply. The FSCDXAN ensures the leg of the circuit with the highest load receives a greater percentage of the flow during dividing mode. It should be noted that this valve functions strictly as a divider; reverse flow through the valve is not recommended. The FSCDXAN features interchangeable cartridges with consistent flow paths and cavity dimensions for a given frame size, allowing for versatile application across various systems. The operational accuracy of this valve is contingent upon proper design considerations to accommodate inherent inaccuracies, especially in systems with rigid mechanical connections between actuators or motors. Such configurations may experience cavitation or lockup due to variations in speed and load distribution. Key specifications include a cavity size of T-31A, series 1 classification, and capacity ranging from 1.5 to 8 gpm (6 to 30 L/min). It operates efficiently at pressures up to 5000 psi (350 bar) with divisional accuracy rates of 6.5% at minimum input flow and 3.5% at maximum input flow. The pressure drop varies from 30 psi (2 bar) at minimum rated input flow to 250 psi (18 bar) at maximum rated input flow. The valve\u2019s hex size measures .78 inches (22.2 mm), and it requires an installation torque between 30-35 lbf ft (41-47 Nm). The model weighs approximately .60 lbs (.30 kg) and utilizes Viton seal kits for optimal performance and durability.

Flow dividers are sliding-spool, pressure-compensated devices used to split oil flow to two different branches of a circuit in a designated ratio. These valves are suitable for applications that use the following: unidirectional hydraulic motors, hydraulic cylinders where flow division in one direction only is required, and multiple circuits that are serviced from one pump supply.

- All flow divider and divider/combiner cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

- Operating characteristics cause the leg of the circuit with the greatest load to receive the higher percentage of flow in dividing mode. If a rigid mechanism is used to tie actuators together, the lead actuator may pull the lagging actuator and cause it to cavitate.

- In applications involving rigid mechanisms between multiple actuators, operating inaccuracy will cause the eventual lock-up of the system. If the mechanical structure is not designed to allow for the operating inaccuracy inherent in the valve, damage may occur.

- In motor circuits, rigid frames or mechanisms that tie motors together, and/or complete mechanical synchronized motion of the output shaft of the motors, either by wheels to the pavement or sprockets to conveyors, will contribute to cavitation, lock-up and/or pressure intensification.

- Variations in speed and lock-up can be attributed to differences in motor displacement, motor leakage, wheel diameter variance and friction of wheels on the driving surface.

- This valve is a divider only; any attempt to flow backwards through the valve is not advised.

- Dividers with unequal ratios have the higher flow at port 4.

- Below the minimum flow rating there is not enough flow for the valve to modulate. It is effectively a tee. If flow starts at zero and rises, there will be no dividing control until the flow reaches the minimum rating.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

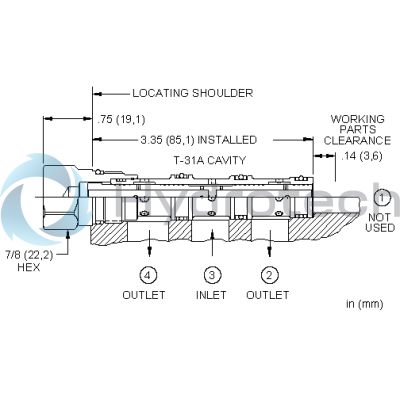

| Cavity | T-31A |

| Series | 1 |

| Capacity | 1.5 - 8 gpm6 - 30 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Divisional Accuracy at Minimum Input Flow | ±6.5%±6.5% |

| Divisional Accuracy at Max Input Flow | ±3.5%±3.5% |

| Pressure Drop at Minimum Rated Input Flow | 30 psi2 bar |

| Pressure Drop at Maximum Rated Input Flow | 250 psi18 bar |

| Rated Input Flow with 50/50 Split | 1.5 - 8 gpm6 - 30 L/min. |

| Rated Input Flow with 40/60 Split | 1.4 - 7 gpm5,3 - 26,5 L/min. |

| Rated Input Flow with 33/67 Split | 1.2 - 6 gpm4,5 - 22,7 L/min. |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Model Weight | .60 lb0,30 kg |

| Seal kit - Cartridge | Viton: 990-031-006 |

Show FAQ