SUN HYDRAULICS

FMDBMCV214N

$229.70 USD

Tags:

- SUN HYDRAULICS

- Material:FMDBMCV214N

- Model:FMDB-MCV@214N

- Summary:Cartridge

Quantity in stock: 0

***Disclaimer: The following summary contains information gathered from various sources such as product descriptions, technical specifications and catalogs. While efforts have been made to provide accurate details, inaccuracies may occur. It is advised to verify all information by contacting Sun Hydraulics directly.***

The Sun Hydraulics FMDBMCV214N (FMDBMCV214N) is a versatile 3-way, meter-in, electro-proportional throttle valve designed for precise flow control in hydraulic systems. In its unenergized state, the valve blocks the supply at port 1 while connecting port 2 to tank at port 3. When the coil is energized, it generates a closing force on the spool, creating a metering orifice in the 1 to 2 direction that is proportional to the coil command current. This valve self-compensates in this direction and can be pressure compensated with an external compensator for enhanced flow control accuracy. The flow from port 2 to port 3 is not proportional. The transition between positions is closed, and using two of these valves can create a 4-way configuration that allows selection from existing flow ranges without requiring a special spool. For pressure compensation, an external modulating logic element such as LRCXHN or LPCXHN may be used. The valve supports pressures up to 5000 psi (350 bar) across all ports and features interchangeable coils with other Sun solenoid-operated valves. For optimal performance, it is recommended to use an amplifier with current sensing and adjustable dither ranging from 100 to 250 Hz. The manual override options include a momentary-twist mechanism that allows temporary actuation by twisting clockwise by 90 degrees. The construction incorporates Sun\u2019s floating style design to minimize internal binding due to installation torque or machining variations. This model fits into cavity T-11A and belongs to Series 1 with a capacity of up to 6 gpm (23 L/min). It has minimal leakage at specified conditions and requires specific installation torque values for proper operation. The valve's design ensures reliable performance in demanding hydraulic applications where precise control is essential.

The Sun Hydraulics FMDBMCV214N (FMDBMCV214N) is a versatile 3-way, meter-in, electro-proportional throttle valve designed for precise flow control in hydraulic systems. In its unenergized state, the valve blocks the supply at port 1 while connecting port 2 to tank at port 3. When the coil is energized, it generates a closing force on the spool, creating a metering orifice in the 1 to 2 direction that is proportional to the coil command current. This valve self-compensates in this direction and can be pressure compensated with an external compensator for enhanced flow control accuracy. The flow from port 2 to port 3 is not proportional. The transition between positions is closed, and using two of these valves can create a 4-way configuration that allows selection from existing flow ranges without requiring a special spool. For pressure compensation, an external modulating logic element such as LRCXHN or LPCXHN may be used. The valve supports pressures up to 5000 psi (350 bar) across all ports and features interchangeable coils with other Sun solenoid-operated valves. For optimal performance, it is recommended to use an amplifier with current sensing and adjustable dither ranging from 100 to 250 Hz. The manual override options include a momentary-twist mechanism that allows temporary actuation by twisting clockwise by 90 degrees. The construction incorporates Sun\u2019s floating style design to minimize internal binding due to installation torque or machining variations. This model fits into cavity T-11A and belongs to Series 1 with a capacity of up to 6 gpm (23 L/min). It has minimal leakage at specified conditions and requires specific installation torque values for proper operation. The valve's design ensures reliable performance in demanding hydraulic applications where precise control is essential.

This valve is a 3-way, meter-in, electro-proportional throttle. The flow path, unenergized, has the supply blocked at port 1 and port 2 connected to tank at port 3. Energizing the coil generates a closing force on the spool, creating a metering orifice in the 1 to 2 direction that is proportional to the coil command current. The valve self-compensates in the 1 to 2 direction and with the addition of an external compensator will provide pressure compensated flow control. Flow in the 2 to 3 direction is not proportional.

- The transition between positions is closed.

- Using 2 3-ways to create a 4-way allows one to choose existing flow ranges instead of cutting a special spool.

- These valves may be pressure compensated by an external, modulating, logic element. Use LR_C-XHN for a bypass circuit or LP_C-XHN for a restrictive circuit.

- The valve provides a degree of self-compensation and may be used as a flow control. To increase the accuracy of flow control, an external, modulating, logic element can be used to maintain a constant flow over a wider range of flows and pressures. See performance curves for additional information.

- All ports will accept 5000 psi (350 bar).

- Coils are interchangeable with Sun's other full flow, solenoid-operated valves and can be mounted on the tube in either direction.

- For optimum performance, an amplifier with current sensing and adjustable dither should be used. Dither should be adjustable between 100 - 250 Hz.

- On models equipped with the D or L control, the detent mechanism in the manual override is meant for temporary actuation. The D, E, L and T manual control assemblies have a mechanical life expectancy of approximately 7,000 cycles.

- The momentary/twist override option "E" allows the operator to shift the valve by twisting the manual override clockwise 90 degrees.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

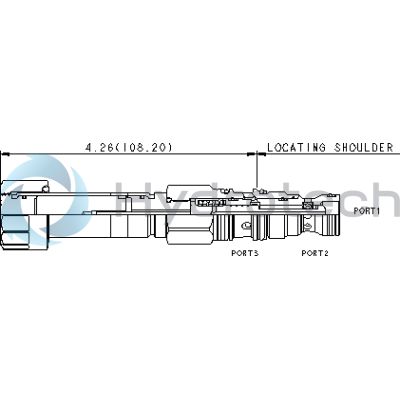

| Cavity | T-11A |

| Series | 1 |

| Capacity | 6 gpm23 L/min. |

| Maximum Valve Leakage at 110 SUS (24 cSt) | 2 in³/min.@1000 psi30 cc/min.@70 bar |

| Manual Override Force Requirement | 5 lbs/1000 psi @ Port 133 N/100 bar @ Port 1 |

| Manual Override Stroke | .10 in.2,5 mm |

| Solenoid Tube Diameter | .75 in.19 mm |

| Valve Hex Size | 7/8 in.22,2 mm |

| Valve Installation Torque | 30 - 35 lbf ft41 - 47 Nm |

| Model Weight (with coil) | 1.10 lb0,50 kg |

| Seal kit - Cartridge | Viton: 990-411-006 |

| Seal and nut kit - Coil | Viton: 990-770-006Viton: 990-770-006 |

Show FAQ