BOSCH REXROTH

R161982500

All Other Products

Other Acc&CP&PP: Front Lube Unit

BOSCH REXROTH

MATERIAL: R161982500

SUMMARY: Other Acc&CP&PP: Front Lube Unit

Quantity in stock: 0

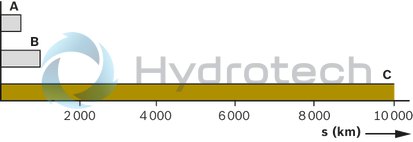

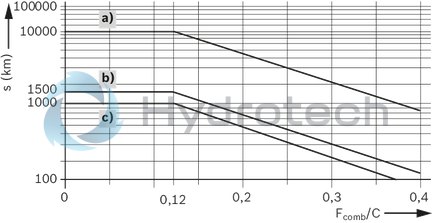

Possible travel distance with front lube units

Previous travel distance s

A With oil lubrication to 500 km B With grease lubrication to 1000 km

Possible travel distance s

C With front lube units to 10,000 km|

Size |

15 | 20 | 25 | 30 | 35 | 45 | 55 | 65 | |

|

possible travel distance s with front lube units |

km |

10000 | 1500 | 1000 | |||||

Compare oil consumption for size 25

|

Front lube units |

Amount of lubricant oil per lubrication cycle |

Travel distance s |

Lubricant oil consumption absolute |

Lubricant oil consumption in comparison |

|

cm³ |

km |

cm³/km |

% |

|

|

without |

1,2 |

20 |

0,06 |

100,00 |

|

with |

5,2 |

5000 |

0,00104 |

1,73 |

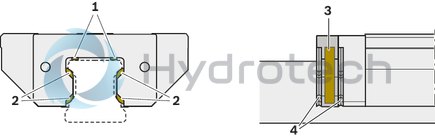

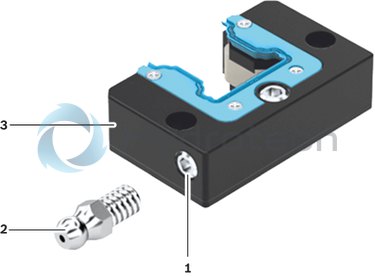

Lubricant distribution

Due to the special lubricant distribution construction, lubrication primarily takes place where it is needed: directly on the running tracks and the top surface of the Ball Guide Rail.

1 Top surface of the ball guide rail

2 Running tracks of the ball bearing guide

3 Oil tank

4 Seals

Front lube unit R1619 2. 00

Material:

special plastic

The front lube units R1619 .2. 00 are already filled with oil (Mobil SHC 639) and can be mounted after basic lubrication of the Ball Runner Block.

Front lube unit R1619 2. 10

Material:

special plastic

The front lube units R1619 2. 10 are left empty at the factory.

General technical data

|

Size |

Part number |

Oil |

maximum operating temperature |

Mass |

|

cm³ |

°C |

g |

||

| 15 | R161912500 | 1 | + 60 | 15 |

| 20 | R161982500 | 2.2 | 20 | |

| R161982600 1) | 1.8 | |||

| 25 | R161922500 | 2.6 | 25 | |

| R161922600 1) | 2.5 | |||

| 30 | R161972500 | 3.85 | 35 | |

| 35 | R161932500 | 5.7 | 50 | |

| 45 | R161942500 | 9.6 | 70 | |

| 55 | R161952500 | 14.5 | 90 | |

| 65 | R161962500 | 30 | 130 |

| 1) | For Ball Runner Blocks F.N (flanged ... low profile) and S.N (slimline ... low profile) |

| a) | Size 65 |

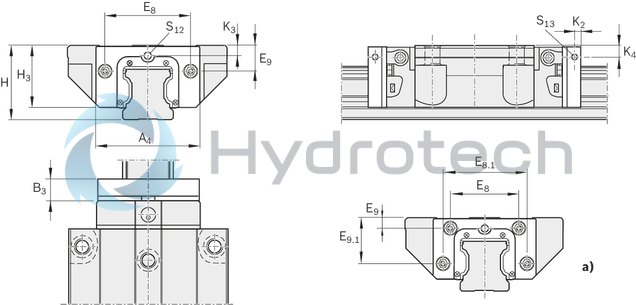

Dimensions

|

Size |

15 | 20 | 25 | 30 | 35 | 45 | 55 | 65 | |||

|

Part number |

R161912500 | R161982500 | R161982600 1) | R161922500 | R161922600 1) | R161972500 | R161932500 | R161942500 | R161952500 | R161962500 | |

|

A4 |

mm |

31.8 | 43 | 41 | 47 | 58.8 | 69 | 84 | 99 | 124.2 | |

|

B3 |

mm |

11.5 | 12.5 | 13 | 14.5 | 16 | 17 | 18 | 19 | ||

|

E8 |

mm |

24.55 | 32.5 | 30.5 | 38.3 | 48.4 | 58 | 69.8 | 80 | 76 | |

|

E8.1 |

mm |

- | 100 | ||||||||

|

E9 |

mm |

6.7 2) | 7.3 2) | 5.6 2) | 11.5 2) | 8.5 2) | 14.6 2) | 17.35 2) | 20.9 2) | 22.3 2) | 11 2) |

|

E9 |

mm |

10.7 2) 3) | - | 15.5 2) 3) | - | 17.6 2) 3) | 24.35 2) 3) | 30.9 2) 3) | 32.3 2) 3) | - | |

|

E9.1 |

mm |

- | 53.5 2) | ||||||||

|

H |

mm |

24 | 30 | 28 | 36 | 33 | 42 | 48 | 60 | 70 | 90 |

|

H 3) |

mm |

28 | - | 40 | - | 45 | 55 | 70 | 80 | - | |

|

H3 2) |

mm |

19.4 | 24.9 | 22.9 | 29.3 | 26.3 | 35.05 | 39.85 | 49.8 | 57.05 | 75.7 |

|

H3 2) 3) |

mm |

23.4 | - | 33.3 | - | 38.05 | 46.85 | 59.8 | 67.05 | - | |

|

K2 |

mm |

5 | - | 5 | 6 | 7 | 8 | ||||

|

K3 2) |

mm |

3.35 | 3.7 | 3.1 | 5.5 | 4.1 | 6.05 | 6.9 | 8.2 | 8.9 | 16 |

|

K3 2) 3) |

mm |

7.35 | - | 9.5 | - | 9.05 | 13.9 | 18.2 | 18.9 | - | |

|

K4 2) |

mm |

3.35 | 3.7 | 3.1 | 5.5 | 4.1 | 6.05 | 6.9 | 8.2 | 8.9 | 16 |

|

K4 2) 3) |

mm |

7.35 | - | 9.5 | - | 9.05 | 13.9 | 18.2 | 18.9 | - | |

|

S12 |

M3 | - | M6 | M3 | M6 | M8 | |||||

|

S13 |

M3 | M6 | M3 | M6 | M8 | ||||||

| 1) | For Ball Runner Blocks F.N (flanged ... low profile) and S.N (slimline ... low profile) |

| 2) | Based on the mounting face of the ball runner block |

| 3) | For ball runner blocks S.H (slimline ... high) |

Prior to assembling the front lube units, initial lubrication of the Ball Runner Blocks with grease lubricant is required! See Ball Rail Systems - General technical notes and information, chapter "Maintenance".

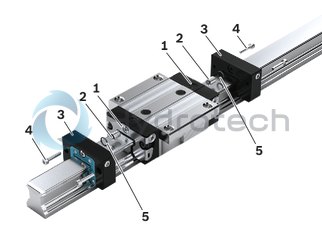

Assembly of front lube units – note for mounting

The parts required for mounting are included (coated screws, seal and lube nipple).

In each case, mount a front lube unit (Picture, Pos.3) on each side of the Ball Runner Block!

Do not pull the Ball Runner Block out of the Ball Guide Rail!

Ball Runner Block up to size 45:

The enclosed lubrication pin (2) must be installed between the lube plate and the Ball Runner Block! (It contains a lube port.)

Remove the set screws (1). Screw in lubrication pin (2). Slide on front lube units (3). Insert O-rings (5) between Ball Runner Block and front lube units. Tighten screws (4) with tightening torque MA Tighten according to the table (see below).

Ball Runner Block from size 55:

Slide on front lube units (3). Remove set screws (1) and insert O-rings (5) between Ball Runner Block and front lube units. Tighten screws (4) with tightening torque MA Tighten according to the table (see below).

Slide on front lube units (3). Remove set screws (1) and insert O-rings (5) between Ball Runner Block and front lube units. Tighten screws (4) with tightening torque MA Tighten according to the table (see below).

Maximum tightening torque MA

|

Size |

Pos. 4  |

Tightening torque MA in Nm |

|

15 |

M2,5 x 12 |

0,3 |

|

20 |

M3 x 14 |

0,6 |

|

25 |

M3 x 14 |

0,6 |

|

30 |

M3 x 14 |

1,2 |

|

35 |

M3 x 16 |

1,2 |

|

45 |

M4 x 18 |

1,6 |

|

55 |

M5 x 18 |

2,0 |

|

65 |

M4 x 20 |

1,6 |

Initial filling of a front lube unit without oil

Remove set screw from the lube port (Fig. 1, item 1) and keep for later use. Tighten lube nipple (2). Lay front lube unit (3) down flat, fill with oil quantity according to table (see below), leave unused for approximately 36 hours. Check whether the lubricant insert is fully soaked with oil. Add oil if necessary. Remove lube nipple. Screw in set screw For size 20 Low: Place front lube units in 10 mm-deep oil for about 36 hours (see Fig. 2).

Fig. 1

Fig. 2

Recommended lubricating oil for initial filling:

Mobil SHC 639 (viscosity 1000 mm2/s at 40 °C)If any oil other than the one specified is used, check the compatibility of lubricants and observe travel distance!

|

Size |

Oil quantity for initial filling of a front lube unit without oil in cm3 |

|

15 |

0,90 |

|

20 |

2,00 |

|

25 |

2,40 |

|

30 |

3,85 |

|

35 |

5,70 |

|

45 |

9,60 |

|

55 |

14,50 |

|

65 |

30,00 |

Relubrication of the front lube units

Once the relubrication interval has been reached according to the diagram (see below), apply the relubrication quantity shown in the table "Oil quantity for initial filling of a front lube unit without oil in cm3" (see chapter "Commissioning").

Relubrication is possible via the lateral lube port. The front lube unit size 20 Low is not refillable via the lube port (see chapter "Commissioning", Fig. 2).

Note

After no more than 3 years Rexroth recommends replacing the front lube units and re-lubricating the Ball Runner Block prior to assembly of the new front lube unit.

Relubrication of the Ball Runner Block

Under clean operating conditions, the Ball Runner Block end faces can be re-lubricated with grease (Dynalub 510).

Relubrication of the Ball Runner Block with grease lubricant see section on lubrication.

Attention:

If other lubricants are used, this may lead to a reduction in lubrication intervals, performance losses with short-stroke applications and load capacities. Possible chemical interactions between the plastic materials, lubricants and preservative oils must also be taken into account. The recommended lubrication intervals depend on environmental factors, load and load type. Examples of environmental factors include swarf, mineral abrasion (or similar), solvent and temperature. Examples of loads and stress types are oscillations, shocks and tilting. The manufacturer is not familiar with the operating conditions. Only the user's own trials and accurate monitoring can yield safety across lubrication intervals. No water-based coolant/lubricant is permitted on the Ball Runner Blocks and Ball Guide Rails!

Load-dependent lubrication intervals for Ball Runner Blocks with front lube units

This applies for the following conditions:

Ball Runner Block lubricants: Dynalub 510 (NLGI 2 grease) or, alternatively, Castrol Longtime PD 2 (NLGI 2 grease) Front lube unit lubricants: Mobil SHC 639 (synthetic oil) Maximum speed: vmax. = 2 m/s No exposure to media Standard seals (SS) Ambient temperature: T = 20 – 30 °C

Definition Fcomb/C

The load ratio Fcomb/C describes the quotient form the equivalent dynamic load with combined load on bearing Fcomb (when considering the internal pre-tensioning force Fpr) and the dynamic load rating C.

a) Size 15, 20, 25, 30, 35, 45

b) Size 55:

c) Size 65

Legend

|

Symbol |

Description |

Unit |

|

C |

Dynamic load capacity |

N |

|

Fcomb |

Dynamic combined equivalent load |

N |

|

Fcomb/C |

Load ratio |

|

|

s |

Lubrication interval as travel distance |

km |