BOSCH REXROTH

M-4SEW10D1X/420MG24N9K4/B20

R900756347

Directional Seat/Poppet Valves

Direct. poppet valves: M-*SEW 10.-1x/

BOSCH REXROTH

MATERIAL: R900756347

SUMMARY: Direct. poppet valves: M-*SEW 10.-1x/

Quantity in stock: 0

3/2 directional seat valve

General

The directional valve of the M-.SEW type is a directional seat valve with solenoid actuation. It controls the start, stop and direction of flow.

It basically comprises a housing (1), the solenoid (2), the hardened valve system (3) and the spool (8) as closing element.

Basic principle

In the initial position, the control spool (8) is pressed onto the seat by the spring (9) and in spool position by the solenoid (2). The force of the solenoid (2) acts via the angled lever (6) and the ball (7) on the spool (8) that is sealed on two sides. The chamber between the two sealing elements is connected to port P. Therefore, the valve system (3) is pressure-compensated in relation to the actuating forces (solenoid or return spring). Therefore, the valves can be used up to 630 bar.

Notice!

3/2-directional seat valves feature "negative spool overlap". Therefore, port T must always be connected. That means that during the switching process – from the starting of the opening of one valve seat to the closing of the other valve seat – ports P–A–T are connected with each other. However, this process takes place within such a period of time that it is irrelevant in nearly all cases of use. The manual override (10) allows for the switching of the valve without solenoid energization.Attention!

It is to be ensured that the maximum flow indicated is not exceeded! If applicable, a throttle insert for flow limitation is to be inserted (see functional description).

The seat arrangement offers the following options:

Control spool symbol “U“

Control spool symbol “C”

Type M-3SEW 10 U…

4/2 directional seat valve

With a sandwich plate, the Plus-1 plate, under the 3/2 directional seat valve, the function of a 4/2 directional seat valve is achieved.

Function of the Plus-1 plate:

Initial position

The main valve is not operated. The spring (9) holds the ball (4) on the seat (11). Port P is blocked and A is connected to T. Apart from that, one control line is connected from A to the large area of the control spool (12), which is thus unloaded to the tank. The pressure applied via P now pushes the ball (13) onto the seat (14). Now, P is connected to B, and A to T.

Transition position:

When the main valve is actuated, the spool (8) is shifted against the spring (9) and pressed onto the seat (15). During this, port T is blocked, while P, A, and B are briefly connected to each other.

Spool position:

P is connected to A. As the pump pressure acts via A on the large area of the control spool (12), the ball (13) is pressed onto the seat (16). Thus, B is connected to T, and P to A. The ball (13) in the Plus-1 plate has a "positive spool overlap".

Attention!

In order to avoid pressure intensification when using differential cylinders, the annulus area of the cylinder must be connected at A.

The use of the Plus-1 plate and the seat arrangement offer the following options:

Control spool symbol “D”

Control spool symbol “Y”

Type M-4SEW 10 Y…

Throttle insert

The use of a throttle insert is required if, due to prevailing operating conditions, flows which exceed the performance limit of the valve can occur during the switching processes.

Examples:

Accumulator operation, use as pilot control valve with internal pilot fluid tapping.3/2 directional seat valve (see functional description)

The throttle insert is inserted into port P of the seat valve.

4/2 directional seat valve (see functional description)

The throttle insert is inserted into port P of the Plus-1 plate.

Check valve insert

The check valve insert allows a free flow from P to A and closes A to P in a leak-free form.

3/2 directional seat valve (see functional description)

The check valve insert is inserted into port P of the seat valve.

4/2 directional seat valve (see functional description)

The check valve insert is inserted into port P of the Plus-1 plate.

|

01 |

Mineral oil |

M |

|||

|

02 |

3 main ports |

3 |

|||

|

4 main ports |

4 |

||||

|

03 |

Seat valve |

SEW |

|||

|

04 |

Size 10 |

10 |

|||

|

05 |

Main ports |

3 |

4 |

||

|

Symbol |

|

● |

– |

U |

|

|

● |

– |

C |

||

|

– |

● |

D |

||

|

– |

● |

Y |

||

|

● = available |

|||||

|

06 |

Component series 10 ... 19 (10 ... 19: unchanged installation and connection dimensions) |

1X |

|||

|

07 |

Operating pressure 420 bar |

420 bar |

|||

|

Operating pressure 630 bar |

630 bar |

||||

|

08 |

Solenoid (air-gap) with detachable coil |

M |

|||

|

09 |

Direct voltage 24 V |

G24 |

|||

|

Nominal voltage 96 V at DC solenoid in operation with alternating voltage (AC voltage mains 110/120 V - 50/60 Hz with an admissible voltage tolerance of +/- 10 %) |

G96 |

||||

|

Nominal voltage 110 V at DC solenoid with operation with AC voltage mains (AC voltage mains 110 V/120 V – 50/60 Hz with an admissible voltage tolerance of +/-10 %) |

G110 |

||||

|

Nominal voltage 205 V at DC solenoid with operation with AC voltage mains (AC voltage mains 230 V – 50/60 Hz with an admissible voltage tolerance of +/- 10 %) |

G205 2) |

||||

|

10 |

With concealed manual override |

N9 |

|||

|

Without manual override |

no code |

||||

|

Electrical connection |

|||||

|

11 |

Individual connection |

||||

|

Without mating connector, with connector DIN EN 175301-803 |

K41;2) |

||||

|

With M12x1 plug-in connection, high-performance version 5-pole, integrated interference protection circuit, operating display with LED |

K72L3) |

||||

|

Spool position monitoring |

|||||

|

12 |

Without position switch |

no code |

|||

|

Monitored spool position "a" |

QMAG24 |

||||

|

Monitored spool position "b" |

QMBG24 |

||||

|

13 |

Without check valve insert, without throttle insert |

no code |

|||

|

With check valve insert |

P |

||||

|

Throttle Ø 1.2 mm |

B12 |

||||

|

Throttle Ø 1.5 mm |

B15 |

||||

|

Throttle Ø 1.8 mm |

B18 |

||||

|

Throttle Ø 2.0 mm |

B20 |

||||

|

Throttle Ø 2.2 mm |

B22 |

||||

|

Seal material |

|||||

|

14 |

NBR seals |

no code |

|||

|

FKM seals (other seals upon request) |

V |

||||

|

Observe compatibility of seals with hydraulic fluid used. |

|||||

|

15 |

Further details in the plain text |

* |

|||

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

|||

|

M |

– |

SEW |

10 |

1X |

/ |

M |

K4 |

/ |

Preferred types and standard units are contained in the EPS (standard price list).

general

|

Size |

10 | ||

|

Weight |

3/2 directional seat valve |

kg |

2 |

|

4/2 directional seat valve |

kg |

3.5 | |

|

Installation position |

any | ||

|

Ambient temperature range |

NBR seals |

°C |

-30 … +50 |

|

FKM seals |

°C |

-20 … +50 | |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

|

Mineral oil |

HL, HLP |

FKM, NBR |

DIN 51524 |

|

|

Bio-degradable |

Insoluble in water |

HEES (synthetic esters) |

FKM |

VDMA 24568 |

|

HETG (rape seed oil) |

FKM, NBR |

|||

|

Soluble in water |

HEPG (polyglycols) |

FKM |

VDMA 24568 |

|

|

Other hydraulic fluids on request |

||||

electrical

|

Voltage type |

Direct voltage | AC voltage | ||

|

Available voltages |

V |

12 / 24 / 42 / 96 / 110 / 205 / 220 1) | 110 / 120 / 230 | |

|

Voltage tolerance (nominal voltage) |

% |

± 10 | ||

|

Power consumption |

W |

30 | ||

|

Duty cycle |

% |

100 | ||

|

Switching time according to ISO 6403 |

ON (without rectifier) |

ms |

25 … 60 | |

|

ON (with rectifier) |

ms |

30 … 70 | ||

|

OFF (without rectifier) |

ms |

10 … 20 | ||

|

OFF (with rectifier) |

ms |

30 … 70 | ||

|

Maximum switching frequency |

Operating pressure ≤350 bar |

1/h |

15000 | |

|

Operating pressure >350 bar |

1/h |

3600 | ||

|

Protection class according to DIN EN 60529 |

IP65 (with mating connector mounted and locked) | |||

|

Maximum surface temperature of the coil 2) |

°C |

120 | ||

| 1) | Special voltages available upon request |

| 2) | Due to the surface temperatures of the solenoid coils, the standards ISO 13732-1 and EN 982 need to be adhered to! |

When establishing the electrical connection, the protective earthing conductor (PE) has to be connected properly.

Inductive position switch type QM: electrical connection

The electric connection is realized via a 4-pole mating connector (separate order) with connection thread M12 x 1.

electrical

|

Connection voltage (DC voltage) |

V |

24 | ||

|

Voltage tolerance (connection voltage) |

+30 %/-15 % | |||

|

Admissible residual ripple |

% |

≤ 10 | ||

|

Max. load capacity |

mA |

400 | ||

|

Switching outputs  |

PNP transistor outputs, load between switching outputs and GND | |||

|

Pinout  |

1 |

V |

24 | |

|

2, 4 |

Switching output |

mA |

400 | |

|

3 |

Earthing (GND) |

V |

0 | |

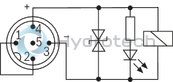

M12x1 plug-in connection

electrical

|

M12x1 plug-in connections 1) |

K72L | ||

|

Available voltages 2) |

V |

24 | |

|

Limited switch-off voltage peak |

V |

-44 … -55 | |

|

Voltage tolerance (nominal voltage) |

% |

± 10 | |

|

Power consumption |

W |

30 | |

|

Duty cycle |

% |

100 | |

|

Switching time according to ISO 6403 |

ON (without rectifier) |

ms |

25 … 60 |

|

ON (with rectifier) |

ms |

30 … 70 | |

|

OFF (without rectifier) |

ms |

10 … 20 | |

|

OFF (with rectifier) |

ms |

30 … 70 | |

|

Maximum switching frequency |

Standard |

1/h |

15000 |

|

Protection class according to DIN EN 60529 3) |

IP40 | ||

|

Protection class according to DIN EN 61140 |

III | ||

|

Maximum coil temperature 4) |

°C |

150 | |

| 1) | Mating connectors according to IEC 60947-5-2, separate order, see data sheet 08006 |

| 2) | Connection to functional low voltage with secure separation only = PELV/SELV |

| 3) | Only with the use of the mating connectors indicated by us and with correct installation. |

| 4) | Due to the surface temperatures of the solenoid coils, the standards ISO 13732-1 and EN 982 need to be adhered to! |

hydraulic

|

Size |

10 | ||

|

Maximum operating pressure |

Port P |

bar |

420 630 |

|

Port A |

bar |

420 | |

|

Port B |

bar |

420 630 |

|

|

Maximum flow |

l/min |

40 | |

|

Hydraulic fluid |

see table | ||

|

Hydraulic fluid temperature range |

NBR seals |

°C |

-30 … +80 |

|

FKM seals |

°C |

-20 … +80 | |

|

Viscosity range |

mm²/s |

2.8 … 500 | |

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) |

Class 20/18/15 according to ISO 4406 (c) | ||

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

For applications outside these parameters, please consult us!

(measured with HLP46, ϑOil = 40 ±5 °C)

Δp-qV characteristic curves ‒ 3/2 directional seat valve

Δp-qV characteristic curves ‒ 3/2 directional seat valve

Δp-qV characteristic curves ‒ 4/2 directional seat valve

Δp-qV characteristic curves ‒ 4/2 directional seat valve

Δp-qV characteristic curves ‒ Check valve insert

Δp-qV characteristic curves ‒ Check valve insert

Δp-qV characteristic curves ‒ throttle insert

Δp-qV characteristic curves ‒ throttle insert

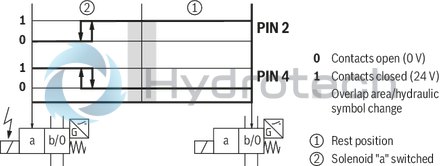

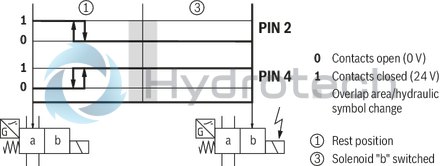

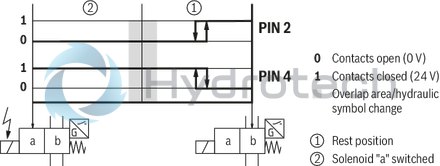

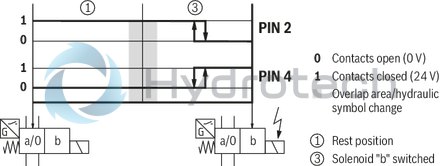

Inductive position switch type QM Switching logics

Version QMA

(Position switch on side B, monitored spool position "a")

Version QMA

(Position switch on side A, monitored spool position "a")

Version QMB

(Position switch on side B, monitored spool position "b")

Version QMB

(Position switch on side A, monitored spool position "b")

Performance limits: (measured with HLP46, ϑoil = 40 ±5 °C)

|

Symbol |

Comment |

||

|

2-way circuit (3/2 directional seat valve) as unloading function only |

U |

|

Before switching from the initial position to the switching position, pressure must be applied to port A. pA ≥ pT |

|

C |

|

pA ≥ pT |

|

|

3-way circuit |

U |

|

pP ≥ pA ≥ pT |

|

C |

|

||

|

4-way circuit (flow only possible in the direction of arrow) |

D |

|

3/2 directional valve (symbol “U”) in connection with Plus-1 plate: pP > pA ≥ pB > pT |

|

Y |

|

3/2 directional valve (symbol “C”) in connection with Plus-1 plate: pP > pA ≥ pB > pT |

|

Attention!

Please observe the general notices on page 12!

The performance limit was determined when the solenoids were at operating temperature, at 10 % undervoltage and without tank preloading.

M12x1 plug-in connection ‒ Individual connection – “K72L”

Pin 5 without function

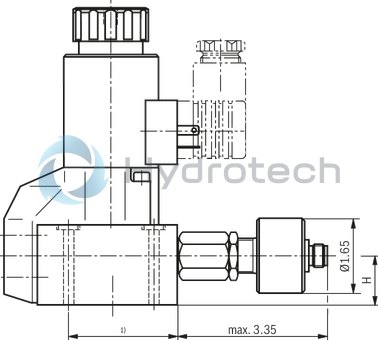

3/2 directional seat valve

Dimensions in mm

3/2 directional seat valve

Dimensions in mm

|

1 |

Solenoid “a” |

|

2 |

Concealed manual override “N9” |

|

3 |

Mating connector without circuitry (separate order) |

|

4 |

Mating connector with circuitry (separate order) |

|

5 |

Space required to remove the coil |

|

6 |

Space required to remove the mating connector |

|

8 |

Name plate |

|

9 |

Mounting nut, tightening torque MA = 4+1 Nm |

|

10 |

Attention! In 3/2 directional seat valves of version “420”, ports B and TB are available as blind counterbore; with version “630”, they are not available. In 4/2 directional seat valves of version “420”, port TB is available as blind counterbore. In 4/2 directional seat valves of version “630”, ports B and TB are not available. |

|

11 |

Same seal rings for ports A, B, TA and TB; seal ring for port P |

|

12 |

Valve mounting screws |

|

13 |

Porting pattern according to ISO 4401-05-04-0-05 |

|

14 |

30 mm (420 bar); 47,5 mm (630 bar) |

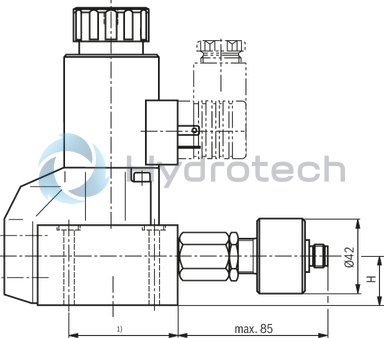

4/2 directional seat valve, version “420”

Dimensions in mm

4/2 directional seat valve, version “420”

Dimensions in mm

|

1 |

Solenoid “a” |

|

2 |

Concealed manual override “N9” |

|

3 |

Mating connector without circuitry (separate order) |

|

4 |

Mating connector with circuitry (separate order) |

|

5 |

Space required to remove the coil |

|

6 |

Space required to remove the mating connector |

|

7 |

Plus-1 plate |

|

9 |

Mounting nut, tightening torque MA = 4+1 Nm |

|

10 |

Attention! In 3/2 directional seat valves of version “420”, ports B and TB are available as blind counterbore; with version “630”, they are not available. In 4/2 directional seat valves of version “420”, port TB is available as blind counterbore. In 4/2 directional seat valves of version “630”, ports B and TB are not available. |

|

11 |

Same seal rings for ports A, B, TA and TB; seal ring for port P |

|

12 |

Valve mounting screws |

|

13 |

Porting pattern according to ISO 4401-05-04-0-05 |

4/2 directional seat valve, version “630”

Dimensions in mm

4/2 directional seat valve, version “630”

Dimensions in mm

Valve mounting screws

3/2 directional seat valve (separate order)

[si]420 bar[/si][imp]6100 psi[/imp] version:4 hexagon socket head cap screws metric

ISO 4762 - M6 x 40 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]12.5 Nm[/si][imp]9.2 ft - lbs[/imp] ± 10 %,

material no. R9130001058

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 40 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]15.5 Nm[/si][imp]11.4 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 1 1/2” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = [si]20 Nm[/si][imp]14.8 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = [si]14 Nm[/si][imp]10.3 ft - lbs[/imp] ± 15 %,

material no. R978800710

[si]630 bar[/si][imp]9150 psi[/imp] version:

4 hexagon socket head cap screws metric

ISO 4762 - M8 x 60 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]30 Nm[/si][imp]22.1 ft - lbs[/imp] ± 10 %,

material no. metric R913000217

or

4 hexagon socket head cap screws

ISO 4762 - M8 x 60 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]37 Nm[si][imp]27.3 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

5/16-18 UNC x 2” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = [si]40 Nm[/si][imp]29.5 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = [si]28 Nm[/si][imp]20.7 ft - lbs[/imp] ± 15 %,

material no. R978800730

4/2 directional seat valve (included in the scope of delivery)

[si]420 bar[/si][imp]6100 psi[/imp] version:4 hexagon socket head cap screws metric

ISO 4762 - M6 x 90 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]12.5 Nm[/si] [imp]9.2 ft - lbs[/imp] ± 10 %,

material no. R913000259

or

4 hexagon socket head cap screws

ISO 4762 - M6 x 90 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]15.5 Nm[si][imp]11.4 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

1/4-20 UNC x 3 1/2” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24 according to ASTM-574);

tightening torque MA = [si]20 Nm[/si][imp]14.8 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17 according to ISO 4762);

tightening torque MA = [si]14 Nm[/si][imp]10.3 ft - lbs[/imp] ± 15 %,

material no. R978800717

[si]630 bar[/si][imp]9150 psi[/imp] version:

4 hexagon socket head cap screws metric

ISO 4762 - M8 x 110 - 10.9 - flZn - 240h - L

(friction coefficient μtotal = 0.09 to 0.14);

tightening torque MA = [si]30 Nm[/si][imp]22.1 ft - lbs[/imp] ± 10 %,

material no. R913000260

or

4 hexagon socket head cap screws

ISO 4762 - M8 x 110 - 10.9 (self procurement)

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]37 Nm[/si][imp]27.3 ft - lbs[/imp] ± 10 %

4 hexagon socket head cap screws UNC

5/16-18 UNC x 4 1/4” (self procurement)

(friction coefficient μtotal = 0.19 to 0.24);

tightening torque MA = [si]40 Nm[/si][imp]29.5 ft - lbs[/imp] ± 15 %,

(friction coefficient μtotal = 0.12 to 0.17);

tightening torque MA = [si]28 Nm[/si][imp]20.7 ft - lbs[i/mp] ± 15 %

Spool position monitoring

Dimensions in mm

Inductive position switch type QM

Dimensions in mm

| 1) | For dimensions, see valve dimensions |

|

Size |

H |

|

mm |

|

| 6 | 23 |

| 10 | 32.5 |

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

M12x1 plug-in connection

Type M-.SEW 10 .-1X/420MG24.K72L…

Dimensions in mm

Type M-.SEW 10 .-1X/420MG24.K72L…

Dimensions in mm

|

6 |

Space required to remove the mating connector |

|

15 |

M12x1 plug-in connection with status LED (mating connector according to IEC 60947-5-2, separate order, see data sheet 08006); electrical connections “K72L”: see Electrical connections |

|

6 |

Space required to remove the mating connector |

|

15 |

M12x1 plug-in connection with status LED (mating connector according to IEC 60947-5-2, separate order, see data sheet 08006); electrical connections “K72L”: see Electrical connections |

|

1 |

Solenoid “a” |

|

2 |

Concealed manual override “N9” |

|

3 |

Mating connector without circuitry (separate order) |

|

4 |

Mating connector with circuitry (separate order) |

|

5 |

Space required to remove the coil |

|

6 |

Space required to remove the mating connector |

|

7 |

Plus-1 plate |

|

8 |

Name plate |

|

9 |

Mounting nut, tightening torque MA = 4+1 Nm |

|

10 |

Attention! In 3/2 directional seat valves of version “420”, ports B and TB are available as blind counterbore; with version “630”, they are not available. In 4/2 directional seat valves of version “420”, port TB is available as blind counterbore. In 4/2 directional seat valves of version “630”, ports B and TB are not available. |

|

11 |

Same seal rings for ports A, B, TA and TB; seal ring for port P |

|

12 |

Valve mounting screws |

|

13 |

Porting pattern according to ISO 4401-05-04-0-05 |

In order to switch the valve safely or maintain its switching position, the pressure situation must be as follows:P ≥ A ≥ T (for design reasons). The ports P, A and TA (3/2 directional seat valve) as well as P, A, B and TA (4/2 directional seat valve) are clearly determined according to their tasks. They must not be arbitrarily exchanged or closed! The flow is only admissible in the direction of arrow. When using the Plus-1 plate (4/2 directional function), the following lower operating values are to be observed:pmin = 8 bar; qV > 3 l/min. The total flow of the valve must not be exceeded.

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z4

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z45

Mating connectors for valves with connector “K4”, without circuitry, standard

3P Z45

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

Mating connectors for valves with connector “K4”, with indicator light

3P Z5L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light

3P Z55L

Mating connectors for valves with connector “K4”, with indicator light

3P Z55L

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

Mating connectors for valves with connector “K4”, with indicator light and Zener diode suppression circuit

3P Z5L1

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

Mating connectors for valves with connector “K4”, with rectifier

3P RZ5

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair

Mating connectors for valves with connector “K4”, with rectifier

3P RZ55

Mating connectors for valves with connector “K4”, with rectifier

3P RZ55

For valves with connector “K4” according to EN 175301-803 and ISO 4400, 2-pole + PE, “large cubic connector” Mating connectors for valves with one or two solenoids (individual connection)Data sheet

Spare parts & repair