BOSCH REXROTH

DREE30-6X/200YMG24K31A1M

R901387950

Proportional Pressure Reducing Control Valves

Prop.press.valves: DRE* 30.-4x/

BOSCH REXROTH

MATERIAL: R901387950

SUMMARY: Prop.press.valves: DRE* 30.-4x/

Quantity in stock: 0

Valves of type DRE(M)E are pilot-operated pressure reducing valves. They are used for operating pressure reduction.

These valves basically consist of a pilot control valve (1) with proportional solenoid (2), a main valve (3) with main spool insert (4), as well as an optional check valve (5). On the proportional solenoid, there is moreover a housing (15) with the control electronics. Supply and command value voltage are applied at the connector (16).

At the factory, the command value pressure characteristic curve is adjusted with little manufacturing tolerance.

Type DREE...

The pressure in channel A is set in a command value-dependent form via the proportional solenoid (2).

In rest position – no pressure in channel B –, the spring (11) holds the main spool (4) in its initial position. The connection from channel B to A is open.

The pressure in channel A acts on the bottom side of the main spool in closing direction, and the pressure of the pilot control valve on the spring side of the main spool in the opening direction from channel B to A.

The pilot oil is taken from channel B and flows through the bore (6) to the constant-current control (9) which keeps the pilot flow constant independent of the pressure drop between channel A and B. From the constant-current control (9), the pilot flow flows through the bores (7) via the valve seat (10), passes the valve poppet (8) and is directed into channel Y to the tank.

The pressure required in channel A is preset at the related amplifier. The proportional solenoid pushes the valve poppet (8) in the direction of the valve seat (10) and limits the pressure in the spring chamber (12) to the set value. In the control position of the main spool (4), the hydraulic fluid flows from channel B to A and generates the pressure in channel A (setting of the pilot control valve plus spring (11)). If the set pressure in A is achieved, the forces at the main spool are balanced.

If the actuator at port A does not move (e. g. cylinder piston at stop) and a lower pressure is set for channel A via the proportional solenoid (2), the main spool (4) closes the connection from B to A and simultaneously opens the connection from channel A to the spring chamber (12) of the main spool (4). In this position, the compression volume in channel A can expand via the pilot control valve (1) and port Y.

For the free flow back from channel A to B, a check valve (5) can optionally be installed.

A pressure gauge connection (13) allows for the control of the reduced pressure in channel A.

Type DREME...

For hydraulic protection against an inadmissibly high electric control current at the proportional solenoid, which imperatively results in excessive pressures in port A, you can optionally install a spring-loaded pressure relief valve as maximum pressure limitation (14). The maximum pressure limitation is pre-set based on the relevant pressure rating.

|

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

||

|

DRE |

30 |

‒ |

6X |

/ |

Y |

G24 |

* |

|

01 |

Proportional pressure reducing valve |

DRE |

|

02 |

Without maximum pressure limitation |

no code |

|

With maximum pressure limitation |

M1) |

|

|

03 |

With integrated control electronics |

E |

|

Size |

||

|

04 |

Size 32 |

30 |

|

05 |

Component series 60 … 69 (60 … 69: unchanged installation and connection dimensions) |

6X |

|

Pressure rating |

||

|

06 |

50 bar |

50 |

|

100 bar |

100 |

|

|

200 bar |

200 |

|

|

315 bar |

315 |

|

|

07 |

Pilot oil return always external, separate and depressurized to the tank |

Y |

|

08 |

With check valve between A and B |

no code |

|

Without check valve |

M |

|

|

Power supply |

||

|

09 |

Direct voltage 24 V |

G24 |

|

10 |

1600 mA version |

no code |

|

800 mA version |

-8 2) |

|

|

Electrical connection |

||

|

11 |

Without mating connector; connector DIN EN 175201-804 |

K31 3) |

|

Electrical interface |

||

|

12 |

Command value 0 … 10 V |

A1 |

|

Command value 4 to 20 mA |

F1 |

|

|

Seal material |

||

|

13 |

NBR seals |

M |

|

FKM seals |

V |

|

|

14 |

Further details in the plain text |

* |

|

1) |

The maximum pressure limitation only serves as protection against overpressure in case of an error in the pilot valve (e. g. in case of contamination or over-current). |

|

|

2) |

Replacement for series 4X. (Attention! External amplifiers only suitable for G24 = 1.6 A solenoid). |

|

|

3) |

Mating connectors, separate order |

|

For applications outside these parameters, please consult us!

general

|

Type |

DRE(M)E | |

|

Size |

32 | |

|

Component series |

6X | |

|

Installation position |

Any | |

|

Weight |

kg |

8.7 |

|

Storage temperature range |

°C |

-20 … +80 |

|

Ambient temperature range |

°C |

-20 … +50 |

hydraulic

|

Type |

DRE(M)E | ||

|

Size |

32 | ||

|

Maximum operating pressure |

bar |

315 | |

|

Maximum operating pressure |

Port A |

bar |

315 |

|

Port B |

bar |

315 | |

|

Maximum set pressure in port A |

Pressure rating 50 bar |

bar |

50 |

|

Pressure rating 100 bar |

bar |

100 | |

|

Pressure rating 200 bar |

bar |

200 | |

|

Pressure rating 315 bar |

bar |

315 | |

|

Minimum set pressure with command value 0 V in channel A or P➀ |

See characteristic curve | ||

|

Maximum pressure relief function |

Pressure rating 50 bar |

bar |

75 |

|

Pressure rating 100 bar |

bar |

130 | |

|

Pressure rating 200 bar |

bar |

230 | |

|

Pressure rating 315 bar |

bar |

350 | |

|

Pilot flow |

l/min |

1 | |

|

Maximum flow |

l/min |

300 | |

|

Hydraulic fluid temperature range |

°C |

-20 … +70 | |

|

Viscosity range |

mm²/s |

15 … 380 | |

|

Maximum admissible degree of contamination of the hydraulic fluid, cleanliness class according to ISO 4406 (c) 1) |

Class 20/18/15 according to ISO 4406 (c) | ||

|

Hysteresis 2) |

% |

± 3 | |

|

Repetition accuracy 2) |

% |

< ± 2 | |

|

Linearity 2) |

% |

± 3.5 | |

|

Manufacturing tolerance of the command value pressure characteristic curve 3) |

% |

± 1.5 | |

|

Step response |

10 ... 90% 4) |

ms |

≈ 160 |

|

90 ... 10% 4) |

ms |

≈ 250 | |

|

10 ... 90% 5) |

ms |

≈ 250 | |

|

90 ... 10% 5) |

ms |

≈ 450 | |

| 1) | The cleanliness classes specified for the components must be adhered to in hydraulic systems. Effective filtration prevents faults and simultaneously increases the life cycle of the components. For the selection of the filters, see www.boschrexroth.com/filter. |

| 2) | from maximum set pressure; does not apply to types "G24-8" |

| 3) | of the maximum set pressure, related to the hysteresis characteristic curve, pressure increasing; does not apply to types “G24-8” |

| 4) | measured with standing hydraulic fluid column, 1.0 liters at port A |

| 5) | measured with standing hydraulic fluid column, 5 liters at port A |

|

Hydraulic fluid |

Classification |

Suitable sealing materials |

Standards |

|

Mineral oils and related hydrocarbons |

HL, HLP, HLPD, HLPP |

NBR / FKM |

DIN 51524 |

|

Flame-resistant - water-free |

HFDU, HFDR |

FKM |

ISO 12922 |

|

Flame-resistant - containing water |

HFC (Fuchs HYDROTHERM 46M, Petrofer Ultra Safe 620) |

NBR |

ISO12922 |

|

Important information on hydraulic fluids: For more information and data on the use of other hydraulic fluids please contact us. The flash point of the process and operating medium used must be 40 K over the maximum solenoid surface temperature.

Flame-resistant - containing water: |

|||

electrical

|

Type |

DRE(M)E | |||

|

Power supply |

Nominal voltage |

mV |

24 | |

|

Lower limit value |

mV |

21 | ||

|

Upper limit value |

mV |

35 | ||

|

Minimum solenoid current |

with 1600 mA - coil |

mA |

≤ 100 | |

|

with 800 mA - coil |

mA |

≤ 100 | ||

|

Maximum solenoid current |

with 1600 mA - coil |

mA |

1760 | |

|

with 800 mA - coil |

mA |

840 | ||

|

Solenoid coil resistance |

Cold value at 20 °C |

with 1600 mA - coil |

Ω |

5.5 |

|

with 800 mA - coil |

Ω |

20.6 | ||

|

Solenoid coil resistance |

Maximum hot value |

with 1600 mA - coil |

Ω |

8.05 |

|

with 800 mA - coil |

Ω |

33 | ||

|

Duty cycle |

% |

100 | ||

|

Current consumption |

A |

1.5 | ||

|

Required fuse protection |

2, time-lag | |||

|

Inputs |

Voltage |

V |

0 … 10 | |

|

Current |

mA |

4 … 20 | ||

|

Outlet |

Actual current value |

1 mV ≙ 1 mA | ||

|

Protection class according to DIN EN 60529 |

IP65 (with mating connector mounted and locked) | |||

(measured with HLP46, ϑOil = 40 ±5 °C)

Pressure in port P dependent on the command value (flow = 0.8 l/min)

Type DRE(M)E

Pressure in channel A dependent on command value (measured with a flow of 0 l/min from B to A as well as related control electronics)

Pressure rating 50 bar

Pressure rating 100 bar

Pressure rating 200 bar

Pressure rating 315 bar

Comparison series 4X-6X / pressure rating 50 bar (with amplifier VT-VSPA1-1-1X with 800 mA coil)

Comparison series 4X-6X / pressure rating 100 bar (with amplifier VT-VSPA1-1-1X with 800 mA coil)

Comparison series 4X-6X / pressure rating 200 bar (with amplifier VT-VSPA1-1-1X with 800 mA coil)

Comparison series 4X-6X / pressure rating 315 bar (with amplifier VT-VSPA1-1-1X with 800 mA coil)

Pressure rating 200 bar (with VT-SSPA1)

Pressure in channel A dependent on the flow Qv

Pressure rating 50 bar

Pressure rating 100 bar

Pressure rating 200 bar

Pressure rating 315 bar

Pressure in port A dependent on pressure in port B

pmin - Qv characteristic curve

Pressure differential from A to B via the check valve

Type DREE-6X/...YM...

Type DREME-6X/...YM...

Type DREE-6X/...Y...

Type DREME-6X/...Y...

|

Pin assignment |

Contact |

Assignment interface "A1" |

Assignment interface "F1" |

|

Power supply |

A |

24VDC(u(t)=21...35V);Imax≤1,5A |

|

|

B |

0V |

||

|

Reference potential actual value |

C |

Reference contact F; 0 V |

Reference contact F; 0 V |

|

Differential amplifier input (command value) |

D |

0 ... 10 V; Re = 100 kΩ |

4 ... 20 mA; Re = 100 kΩ |

|

E |

Reference potential command value |

||

|

Measuring output (actual value) |

F |

0 to 1.6 V actual value (1 mV ≙ 1 mA); |

|

|

PE |

connected to solenoid and valve housing |

||

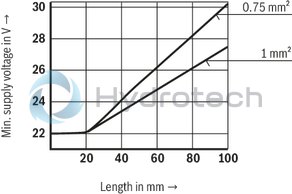

Connection cable

| 1) | Connection cable:- Recommendation 6-wire, 0.75 or 1mm2 plus protective earthing conductor and screening- Connect screening to PE on supply side only- Maximum admissible length 100 m The minimum supply voltage at the power supply unit depends on the length of the supply line (see diagram) |

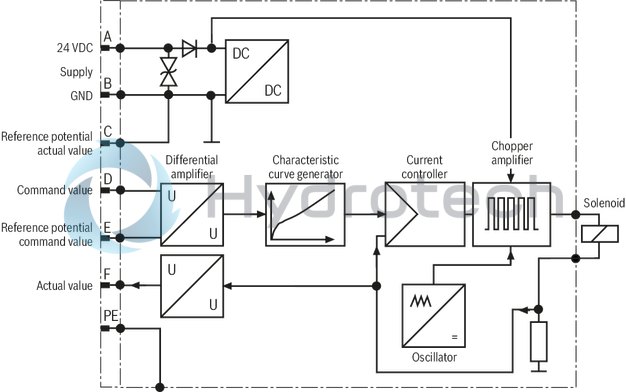

Integrated electronics (OBE)

Function

The electronics are supplied with voltage via ports A and B. The command value is applied to the differential amplifier ports D and E.Via the characteristic curve generator, the command value solenoid current characteristic curve is adjusted to the valve so that non-linearities in the hydraulic system are compensated and thus, a linear command value pressure characteristic curve is created.The current controller controls the solenoid current independently of the solenoid coil resistance.The power stage of the electronics for controlling the proportional solenoid is a chopper amplifier with a clock frequency of approx. 180 Hz to 400 Hz. The output signal is pulse-width modulated (PWM). For checking the solenoid current, a voltage can be measured at the connector between pin F(+) and pin C(–) which is proportional to the solenoid current. 1 mV corresponds to 1 mA solenoid current.

Block diagram / pin assignment

|

1 |

Upon delivery, this port (G1/4) is closed. After removal of the blanking plug, an external and separate depressurized pilot oil return to the tank is, however, also possible here. |

|

2 |

Space required to remove the mating connector |

|

3 |

Name plate |

|

4 |

Maximum pressure limitation with version DREM and DREME |

|

5 |

Check valve, optional |

|

6 |

Locating pin |

|

7 |

Pilot oil return always external, separate and depressurized to the tank |

|

8 |

Blind counterbore |

|

9 |

Identical seal rings for ports A and B |

|

10 |

Identical seal rings for port Y and blind counterbore (pos. 8) |

|

11 |

Pressure gauge connection G1/4; 12 deep |

|

12 |

mating connector according to DIN EN 175301-803 |

|

13 |

Mating connector according to DIN EN 175201-804 |

|

14 |

Integrated electronics (OBE) |

|

15 |

Space required to remove the mating connector |

|

16 |

Cable fastening |

Recommended valve mounting screws (separate order):

6 hexagon socket head cap screws ISO 4762 - M10 x 70 - 10.9-flZn-240h-L

(Friction coefficient μtotal = 0.09 to 0.14)

Tightening torque MA = 60 Nm ± 10%

Material no. R00002245 (separate order) or

6 hexagon socket head cap screws ISO 4762 - M10 x 70 - 10.9

(Friction coefficient μtotal = 0.12 to 0.17)

Tightening torque MA = 75 Nm ± 10%

Notice:

The dimensions are nominal dimensions which are subject to tolerances.

Mating connectors for valves with round connector, 6-pole + PE

7P Z31

Mating connectors for valves with round connector, 6-pole + PE

7P Z31

For valves with round connector according to EN 175201-804, 6-pole + PE as well as 6-pole, compatible with VG 95328Data sheet

Spare parts & repair