Hydrotech ecommerce supports the continental US only

SUN HYDRAULICS CORP

FSFHXAN

Speciality

Cartridge

$845.00

SUN HYDRAULICS CORP

MATERIAL: FSFHXAN

SUMMARY: Cartridge

Quantity in stock: 2

Quantity Details:- Hydrotech Stock: 0 can ship April 22, 2024

- Factory Stock: 2 can ship July 22, 2024

High-capacity, closed-center flow divider/combiners are sliding-spool, pressure-compensated devices used to split flow in one direction and combine flow in the opposite direction. These valves have approximate 15% greater capacity than standard closed-center divider/combiners and are designed for use in tractive drive systems. Note: Accuracy on these cartridges is not equivalent to the accuracy of standard closed-center divider/combiners.

- All flow divider and divider/combiner cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

- Operating characteristics cause the leg of the circuit with the greatest load to receive the higher percentage of flow in dividing mode. If a rigid mechanism is used to tie actuators together, the lead actuator may pull the lagging actuator and cause it to cavitate.

- In combining mode, compensating characteristics will cause the leg of the circuit with the lowest load to receive the higher percentage of flow. If a synchronization feature is not included, an additive accuracy error will be experienced with each full stroke of the actuator.

- In applications involving rigid mechanisms between multiple actuators, operating inaccuracy will cause the eventual lock-up of the system. If the mechanical structure is not designed to allow for the operating inaccuracy inherent in the valve, damage may occur.

- In motor circuits, rigid frames or mechanisms that tie motors together, and/or complete mechanical synchronized motion of the output shaft of the motors, either by wheels to the pavement or sprockets to conveyors, will contribute to cavitation, lock-up and/or pressure intensification.

- Variations in speed and lock-up can be attributed to differences in motor displacement, motor leakage, wheel diameter variance and friction of wheels on the driving surface.

- Extreme pressure intensification can occur on multiple wheel drive vehicles.

- Differential slip for tractive drive systems must be achieved with orifices in the body/manifold.

- Divisional and combining accuracy are equal.

- Below the minimum flow rating there is not enough flow for the valve to modulate. It is effectively a tee. If flow starts at zero and rises, there will be no dividing or combining control until the flow reaches the minimum rating.

- Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge machining variations.

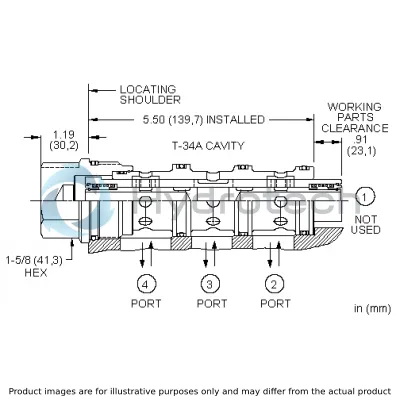

| Cavity | T-34A |

| Series | 4 |

| Capacity | 15 - 70 gpm60 - 270 L/min. |

| Maximum Operating Pressure | 5000 psi350 bar |

| Divisional Accuracy at Minimum Input Flow | 50% ±6.5%50% ±6.5% |

| Divisional Accuracy at Max Input Flow | 50% ±3.5%50% ±3.5% |

| Pressure Drop at Minimum Rated Input Flow | 30 psi2 bar |

| Pressure Drop at Maximum Rated Input Flow | 350 psi24 bar |

| Valve Hex Size | 1 5/8 in.41,3 mm |

| Valve Installation Torque | 350 - 375 lbf ft475 - 508 Nm |

| Model Weight | 2.80 lb1,30 kg |

| Seal kit - Cartridge | Viton: 990-034-006 |

Show FAQ