A jet engine manufacturer needed a better way to accurately measure and record pressures and flows of two types of manifolds.

A jet engine manufacturer needed a better way to accurately measure and record pressures and flows of two types of manifolds.

Too Many Failures at Assembly

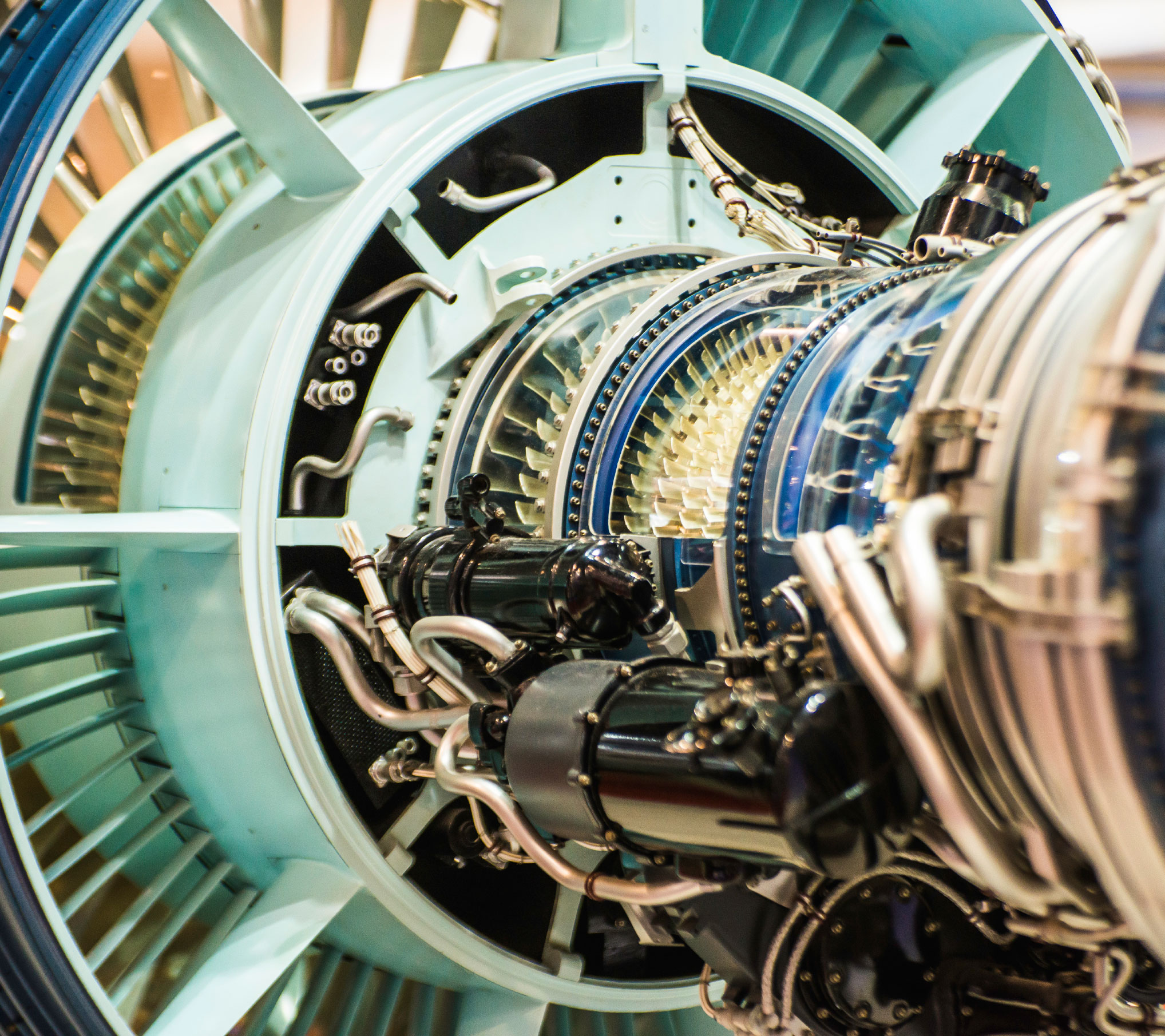

This manufacturer's jet engine is used to drive a turbine, which in turn generates electricity. Jet engines are expensive and, unsurprisingly, customers want their engines to last as long as possible. For a long-lasting engine, it's critical that the engine's high and low pressure hydraulic functions cool as quickly as possible.

Two different manifolds are responsible for bringing coolant to the hydraulics.

The manifolds were manufactured and then sent directly to contractors for engine assembly. While it may have sped up delivery times, this process caused a further problem. The manifolds didn't always work—causing delays and lost production.

The jet engine manufacturer needed a custom test stand to test the manifolds quickly before shipping. The test stand needed to accurately simulate engine flow and pressures, both high and low, as well as withstand the rigors of daily use. Ideally, it could also test other manifolds with similar requirements from this same manufacturer.

Fortunately, Cincinnati-based industrial solutions provider Hydrotech, Inc.(https://www.hydrotech.com) was experienced in creating custom-designed industrial test stands.

Simulating a Jet Engine Startup

Test stands aren't easy to design. The engineers at Hydrotech had to simulate the actual pressure variations and piloting operations of a jet engine—all in a compact box. The test stand Hydrotech built simulates flows of two gallons per minute (gpm) and 3 gpm at pressures ranging from 0 pounds pressure per square inch (psi) to 2,580 pounds psi.

The manifolds had to send out enough coolant to cool the hydraulics, but not too much. The common thinking is more coolant the better. However, too much coolant can create more heat in the engine due to friction. The test stand critically tested velocity and viscosity of the coolant coming from the manifolds.

A complete circuit design was required for approval, as well as specific written test and inspection procedures. All testing and inspection must follow the written guidelines and results must be documented. The test stand was designed to accommodate a production test environment, as well as to be utilized for future testing of other manifolds and components.

Dozens of Tests In Less Than 60 Minutes

The new test stand runs each manifold through thru dozens of tests in less than 60 minutes. Manifolds can now be tested in real-world situations before being shipped to contractors without sacrificing significant shipping delay. The problems and adjustments at start-up were eliminated, thereby reducing the high cost in trouble shooting at contractor sites.

The final product included functions to test other manifolds and assemblies, making the test stand designed by Hydrotech a factory-wide asset.